264 8 Programming: Cycles

8.4 Cycles for milling pockets, studs and slots

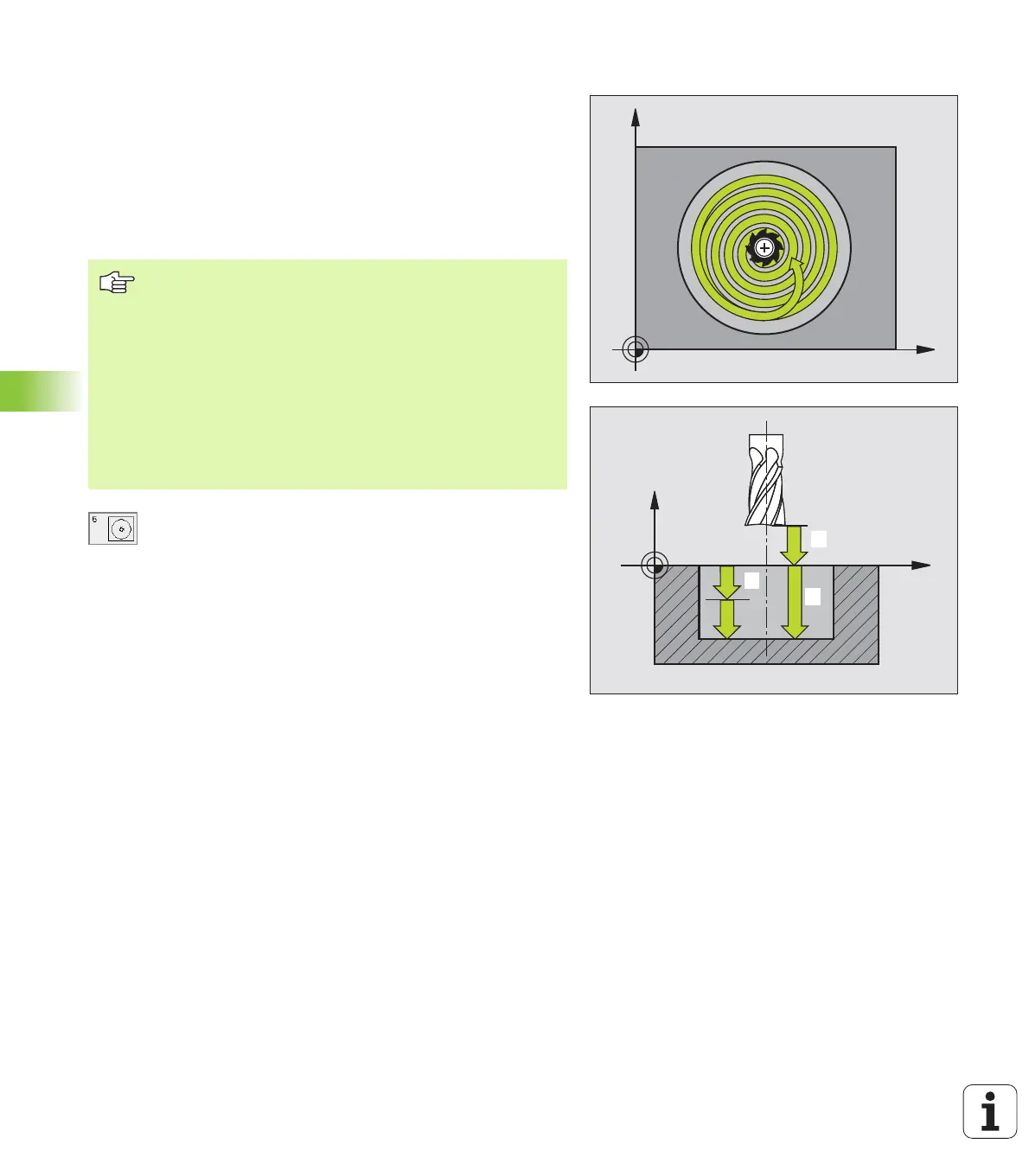

CIRCULAR POCKET MILLING (Cycle 5)

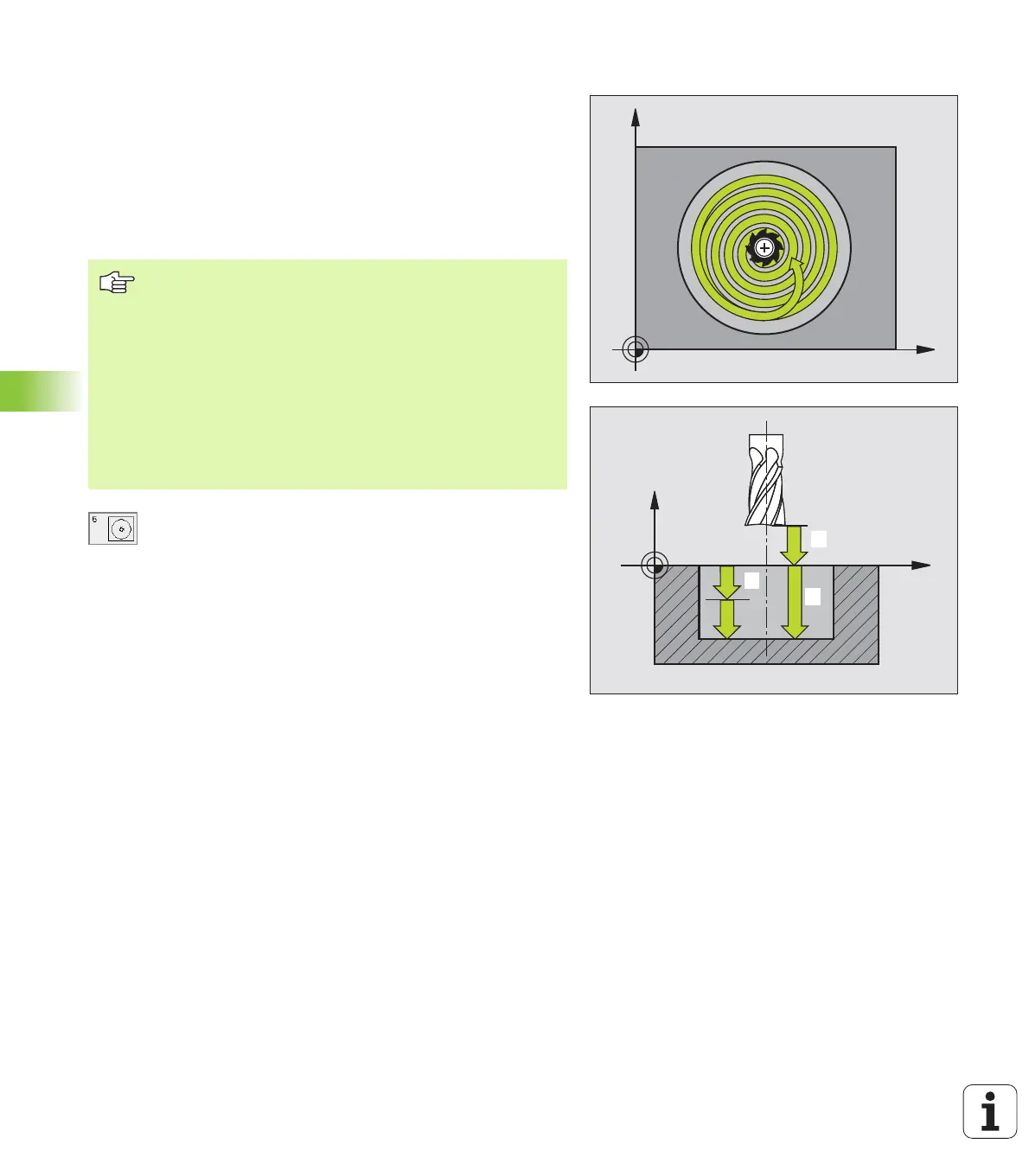

1 The tool penetrates the workpiece at the starting position (pocket

center) and advances to the first plunging depth.

2 The tool subsequently follows a spiral path at the feed rate F - see

figure at right. For calculating the stepover factor k, see Cycle 4

POCKET MILLING.see “POCKET MILLING (Cycle 4),” page 258

3 This process is repeated until the depth is reached.

4 At the end of the cycle, the TNC retracts the tool to the starting

position.

U Set-up clearance 1 (incremental value): Distance

between tool tip (at starting position) and workpiece

surface

U Milling depth 2: Distance between workpiece

surface and bottom of pocket

U Plunging depth 3 (incremental value): Infeed per cut

The TNC will go to depth in one movement if:

n the plunging depth is equal to the depth

n the plunging depth is greater than the depth

X

Y

X

Z

1

1

1

2

1

3

Before programming, note the following:

This cycle requires a center-cut end mill (ISO 1641), or pilot

drilling at the pocket center.

Pre-position over the pocket center with radius

compensation R0.

Program a positioning block for the starting point in the

tool axis (set-up clearance above the workpiece surface).

The algebraic sign for the cycle parameter DEPTH

determines the working direction. If you program DEPTH

= 0, the cycle will not be executed.

Loading...

Loading...