I English

(2)

(3)

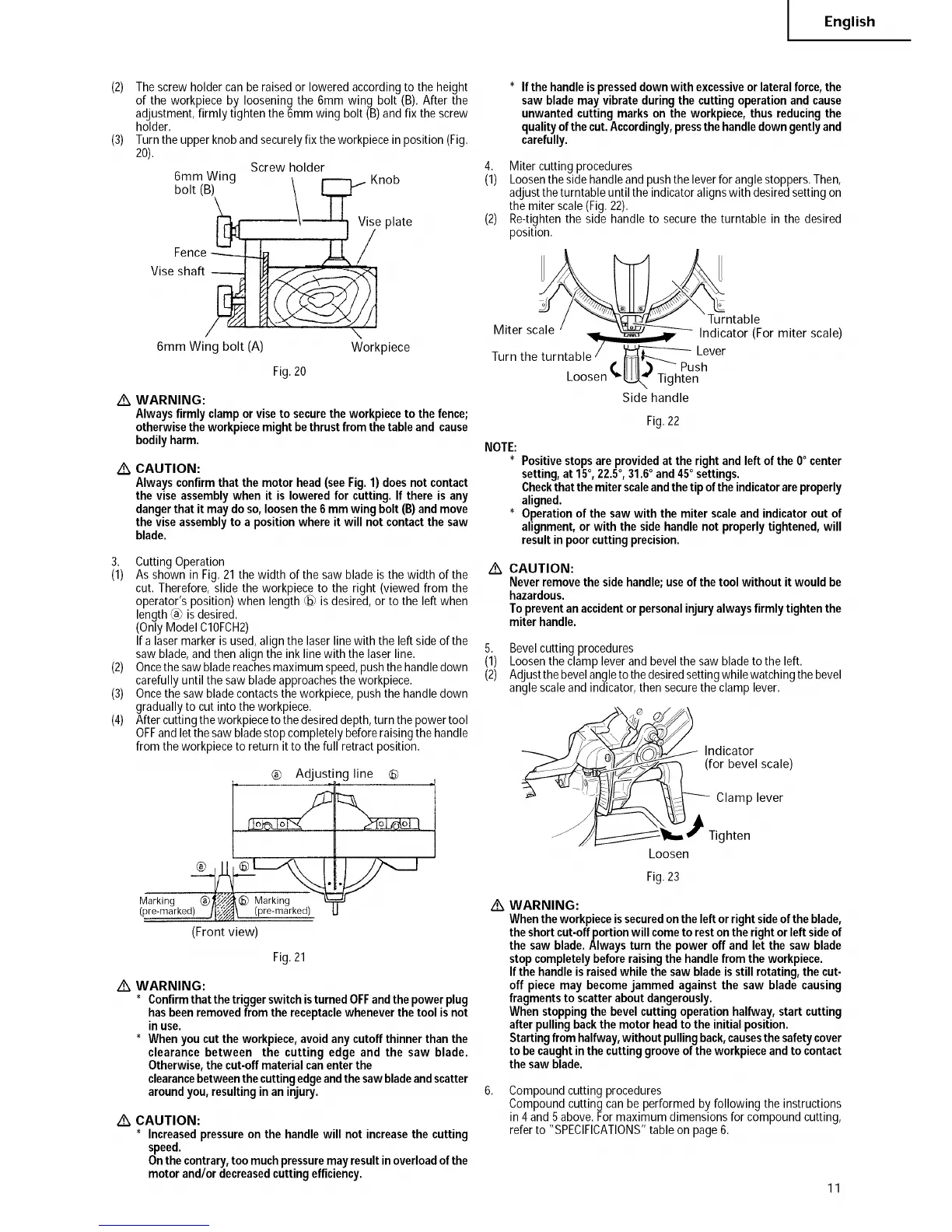

Thescrewholder canbe raisedor lowered accordingto the height

of the workpiece by loosening the 6mm wing bolt (B). After the

adjustment,firmly tighten the 6mm wing bolt (B)andfix the screw

holder.

Turnthe upper knoband securelyfix the workpiecein position (Fig.

20),

Screw holder

6mm Wing _ _ _ Knob

bolt (B) \ I.,_.! f

Viseg:#:f_ _ ise plate

/ "\

6mm Wing bolt (A) Workpiece

Fig.20

Z_ WARNING:

Alwaysfirmly clamporviseto securetheworkpieceto thefence;

otherwisetheworkpiecemightbethrustfrom thetableand cause

bodilyharm.

Z_ CAUTION:

Alwaysconfirmthatthe motorhead (seeFig. 1)doesnot contact

the viseassemblywhen it is loweredfor cutting.If there is any

dangerthat itmaydoso,loosenthe6 mmwing bolt(B)andmove

theviseassemblyto a positionwhereit will not contactthe saw

blade.

3. Cutting Operation

(1) As shown in Fig.21the width of the saw blade is the width of the

cut. Therefore, slidethe workpiece to the right (viewed from the

operator's position) when length @ is desired, or to the left when

length_ is desired.

(OnlyModel C10FCH2)

If a lasermarkeris used, alignthe laser line with the leftside of the

saw blade,and then align the ink linewith the laser line.

(2) Oncethesawbladereachesmaximumspeed,pushthehandledown

carefullyuntil the saw bladeapproachesthe workpiece.

(3) Oncethe saw blade contactsthe workpiece,pushthe handledown

gradually to cut into the workpiece.

(4) Aftercutting theworkpieceto the desireddepth,turn the powertool

OFFand letthe sawbladestop completelybeforeraising the handle

from the workpieceto return it to thefull retract position.

® Adjusti

Marking ® @ Marking

(pre-_arked) ®_:_ (pre-_arked)

(Front view)

ng line ®

Fig.21

Z_ WARNING:

* Confirmthat thetriggerswitchisturnedOFFandthepowerplug

hasbeenremovedfrom thereceptaclewheneverthetool isnot

in use.

* Whenyou cuttheworkpiece,avoidanycutoffthinnerthanthe

clearance between the cutting edge and the saw blade.

Otherwise,thecut-offmaterialcanenterthe

clearancebetweenthecuttingedgeandthesawbladeandscatter

aroundyou, resultingin an injury.

Z_ CAUTION:

* Increasedpressureon the handlewill not increasethe cutting

speed.

Onthecontrary,toomuchpressuremayresultinoverloadofthe

motorand/or decreasedcuttingefficiency.

* Ifthe handleis presseddownwith excessiveorlateral force,the

sawblademay vibrateduringthe cuttingoperationandcause

unwantedcutting markson the workpiece,thus reducingthe

qualityofthecut.Accordingly,pressthehandledowngentlyand

carefully.

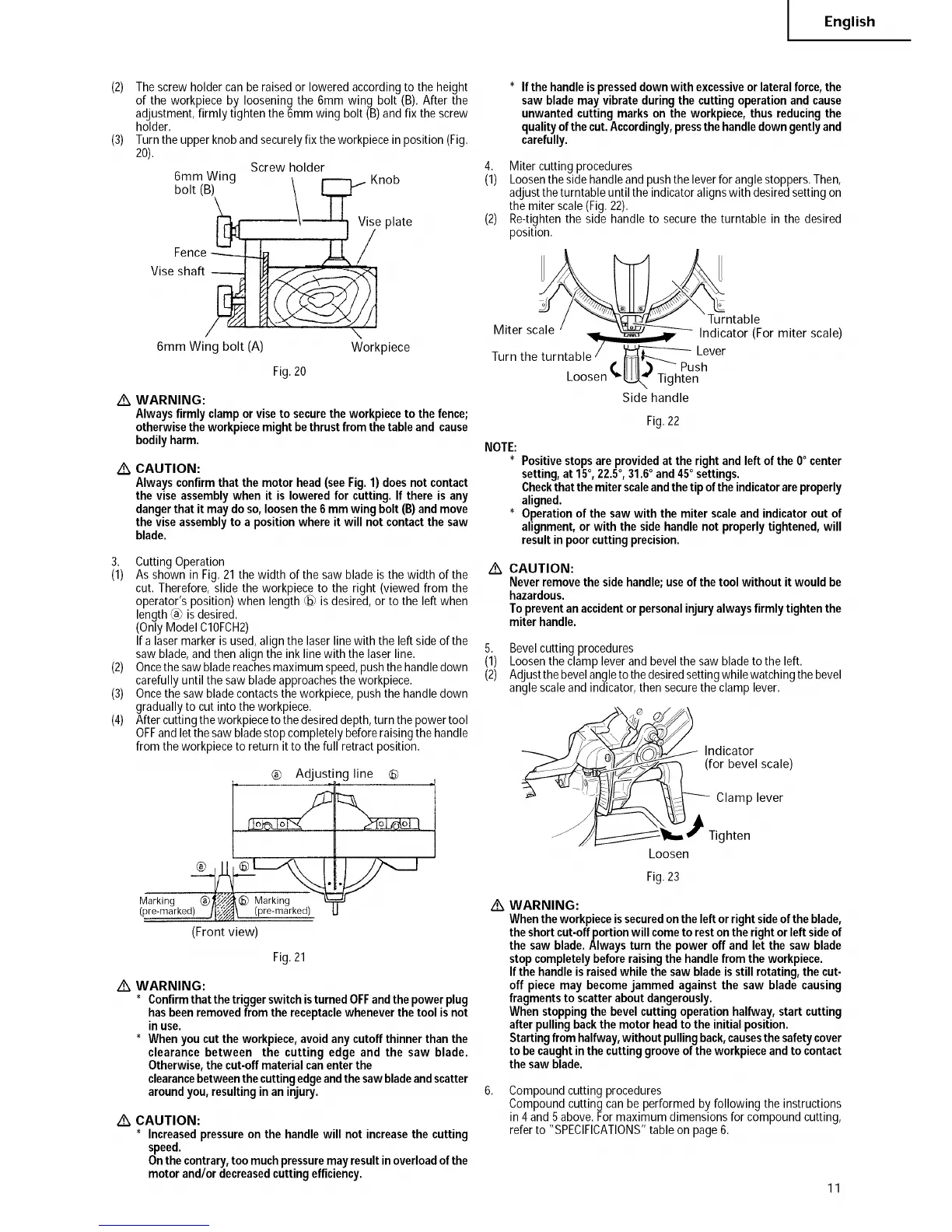

4. Miter cutting procedures

(1) Loosenthe side handleand pushthe leverfor anglestoppers.Then,

adjusttheturntable until the indicatoralignswith desiredsetting on

the miter scale(Fig.22).

(2) Re-tightenthe side handle to securethe turntable in the desired

position.

]urntable

Miter scale Indicator (For miter scale)

Turn the turntable

Lever

I'/ ill_ _Push

Loosen "_ Tighten

Side handle

Fig. 22

NOTE:

* Positivestopsareprovidedat the rightandleft of the 0° center

setting,at 15°, 22.5°, 31.6° and450settings.

Checkthatthemiterscaleandthetip oftheindicatorareproperly

aligned.

* Operationof the saw with the miter scaleandindicatorout of

alignment,orwith thesidehandlenot properlytightened,will

resultin poorcuttingprecision.

/k CAUTION:

Neverremovethe sidehandle;useofthetoolwithout it would be

hazardous.

Topreventanaccidentorpersonalinjuryalwaysfirmly tightenthe

miterhandle.

5. Bevelcutting procedures

(1) Loosenthe clamp leverand bevelthe saw bladeto the left.

(2) Adjustthebevelangleto the desiredsettingwhilewatchingthe bevel

angle scaleand indicator,then securethe clamp lever.

I(fn°d_cbal°ri scale)

_ Clamp lever

__P_ Tighten

Loosen

Fig.23

/k

WARNING:

Whentheworkpieceissecuredontheleftorrightsideofthe blade,

theshortcut-offportionwillcometo restontherightorleftsideof

the saw blade.Alwaysturn the poweroff and let the saw blade

stopcompletelybeforeraisingthe handlefrom theworkpiece.

Ifthe handleis raisedwhilethe saw bladeisstill rotating,the cut-

off piecemay becomejammed againstthe saw blade causing

fragments to scatteraboutdangerously.

Whenstoppingthe bevelcuttingoperationhalfway,startcutting

afterpullingbackthe motorheadto theinitialposition.

Starting from halfway,withoutpullingback,causesthesafetycover

to becaughtinthecuttinggrooveof theworkpieceandto contact

thesaw blade.

Compoundcutting procedures

Compoundcutting canbe performed by following the instructions

in 4and 5 above.Formaximum dimensions for compound cutting,

refer to "SPECIFICATIONS"table on page6.

11

Loading...

Loading...