. A complete Parts List is available at www.HobartWelders.com

OM-260 273 Page 14

5-4. Installing Welding Gun

260 458-A

1 Drive Assembly

2 MIG Gun

3 Gun Securing Thumbscrew

4 Gun End

Loosen thumbscrew. Insert end

through opening until it bottoms

against drive assembly. Tighten

thumbscrew.

Welding gun must be inserted

completely to prevent leakage of

shielding gas.

5 Gun Trigger Plug

Insert plug into receptacle, and

tighten threaded collar.

6 Spool Gun/MIG Gun Switch

Place switch in MIG Gun position.

Close door.

. Be sure that gun end is tight against drive assembly.

4

Correct Gun

Fully Seated

4

Incorrect Gun

Not Seated

Exposed O-rings

will cause shielding

gas leakage.

Spool Gun

5

MIG Gun

6

1

3

2

4

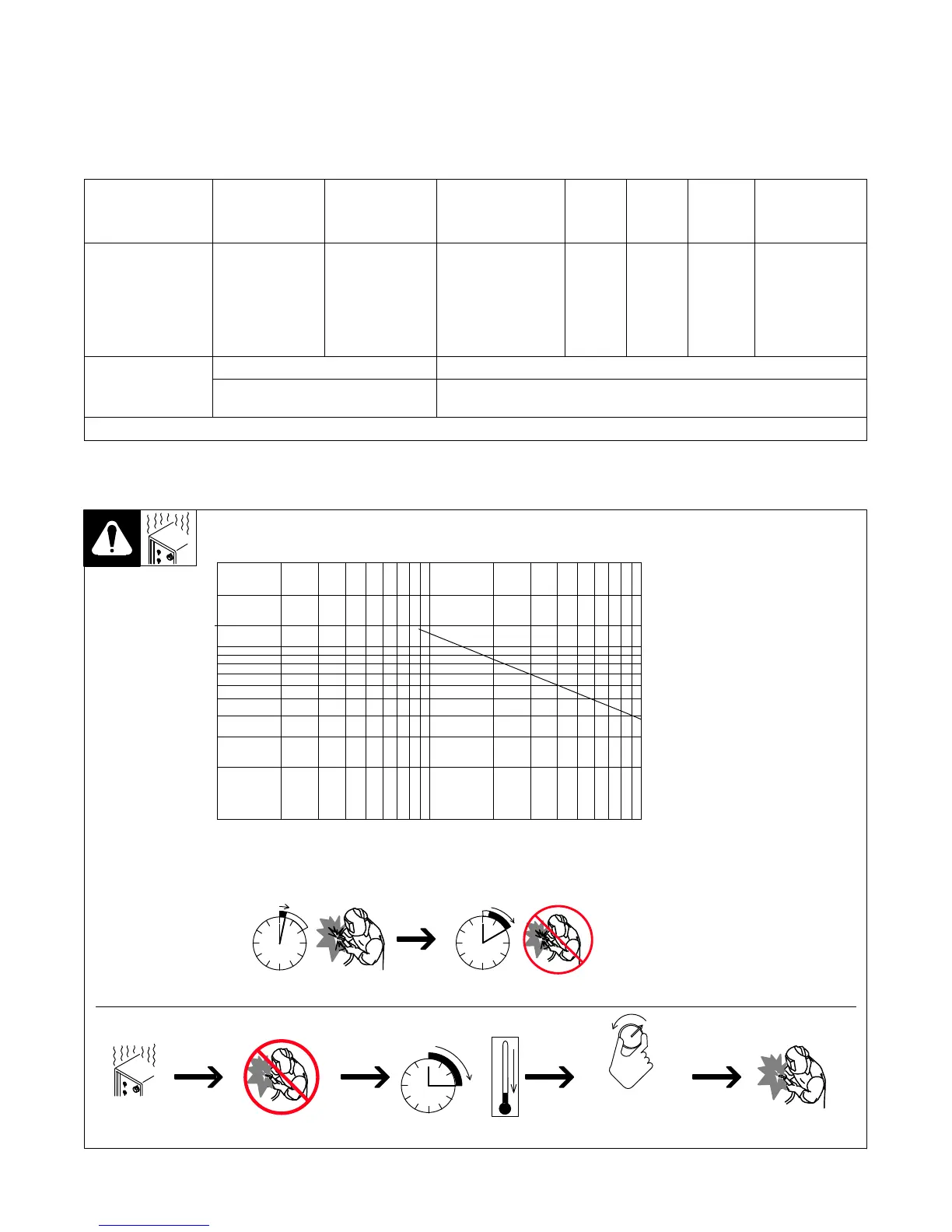

5-5. Process/Polarity Table

Process Polarity

Cable Connections

Cable To Gun Cable To Work

GMAW − Solid wire with shielding gas DCEP − Reverse Polarity Connect to positive (+) output

terminal

Connect to negative (−) output terminal

FCAW − Self-shielding wire − no

shielding gas

DCEN − Straight Polarity Connect to negative (−) output

terminal

Connect to positive (+) output terminal

5-6. Changing Polarity

! Turn off welding power

source.

1 Lead Connections For Direct

Current Electrode Negative

(DCEN)

2 Lead Connections For Direct

Current Electrode Positive

(DCEP)

Always read and follow wire

manufacturer’s recommended

polarity, and see Section 5-5.

Close door.

260 459-A

1

CHANGING

POLARITY

DCEN

Electrode negative

for flux cored wire

DCEP

Electrode positive

for solid wire

2

Loading...

Loading...