OM-260 273 Page 28

SECTION 9 − GMAW WELDING (MIG) GUIDELINES

Wire Feeder/

Power Source

Workpiece

Gun

Regulator/

Flowmeter

Gas

Shielding Gas

Work Clamp

9-1. Typical GMAW (MIG) Process Connections

! Weld current can damage

electronic parts in vehicles.

Disconnect both battery

cables before welding on a

vehicle. Place work clamp as

close to the weld as possible.

GMAW1 2013−05 (GMAW Only) − Ref. 801 909-A

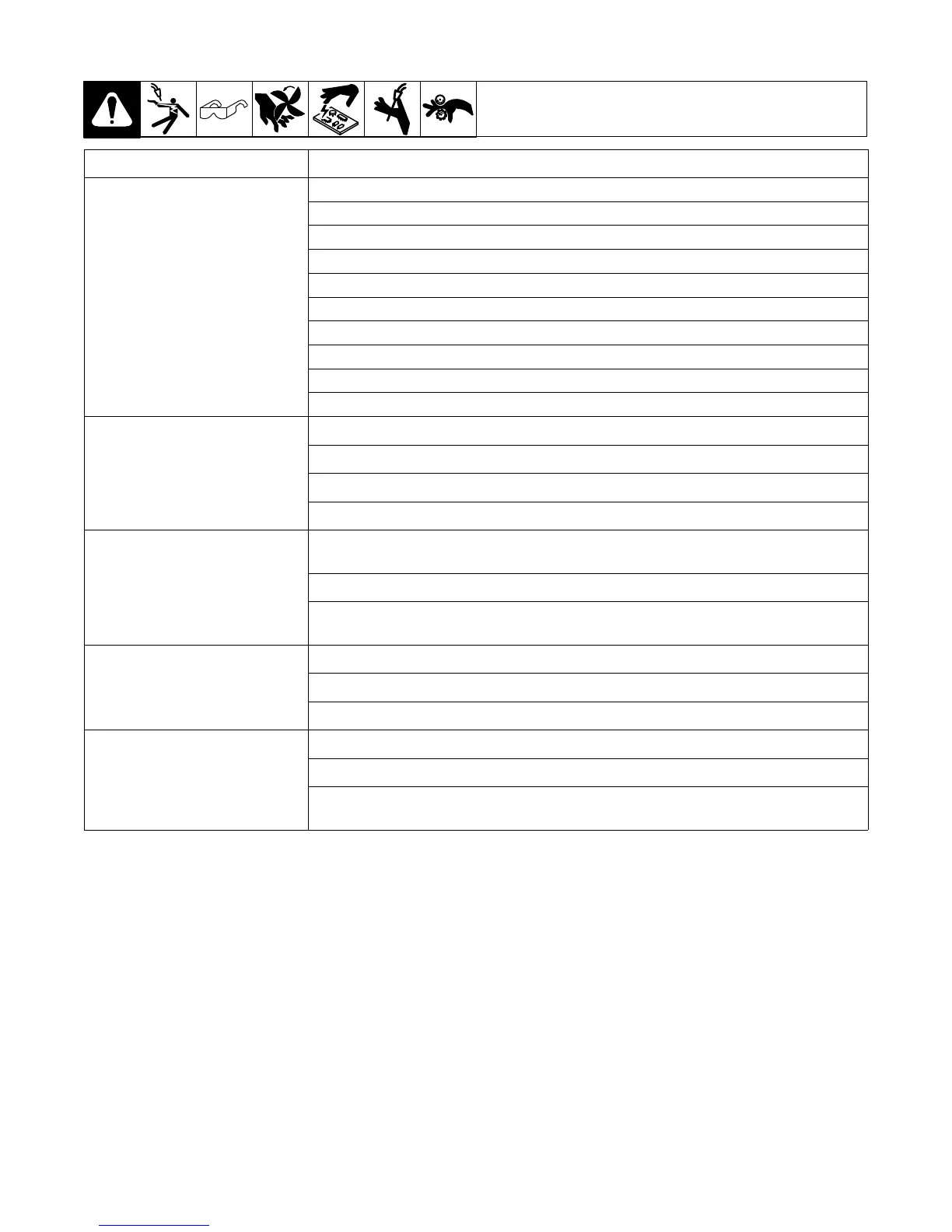

9-2. Typical GMAW (MIG) Process Control Settings

. These settings are guidelines only. Material and wire type, joint design, fitup, position, shielding gas, etc. affect settings. Test welds to be sure

they comply to specifications.

3.5 x 125 A = 437 ipm

2 x 125 A = 250 ipm

1.6 x 125 A = 200 ipm

30 − 90 A

40 − 145 A

50 − 180 A

Convert Material

Thickness to

Amperage (A)

Material thickness determines weld

parameters.

.035 in

Recommendation

Wire Speed

(Approx.)

1/8 or 0.125 in.

(0.001 in. = 1 ampere)

0.125 in. = 125 A

Wire Size Amperage Range

0.023 in.

0.030 in.

0.035 in.

Select Wire Size

Wire

Size

0.023 in.

0.030 in.

0.035 in.

3.5 in. per ampere

2 in. per ampere

1.6 in. per ampere

Select Wire Speed (Amperage)

125 A based on 1/8 in.

material thickness

ipm = inches per minute

Low voltage: wire stubs into work

High voltage: arc is unstable (spatter)

Set voltage midway between high/low voltage

Select Voltage

Voltage controls height and

width of weld bead.

Wire speed (amperage) controls weld

penetration (wire speed = burn-off rate)

Loading...

Loading...