123

Scheduled Maintenance

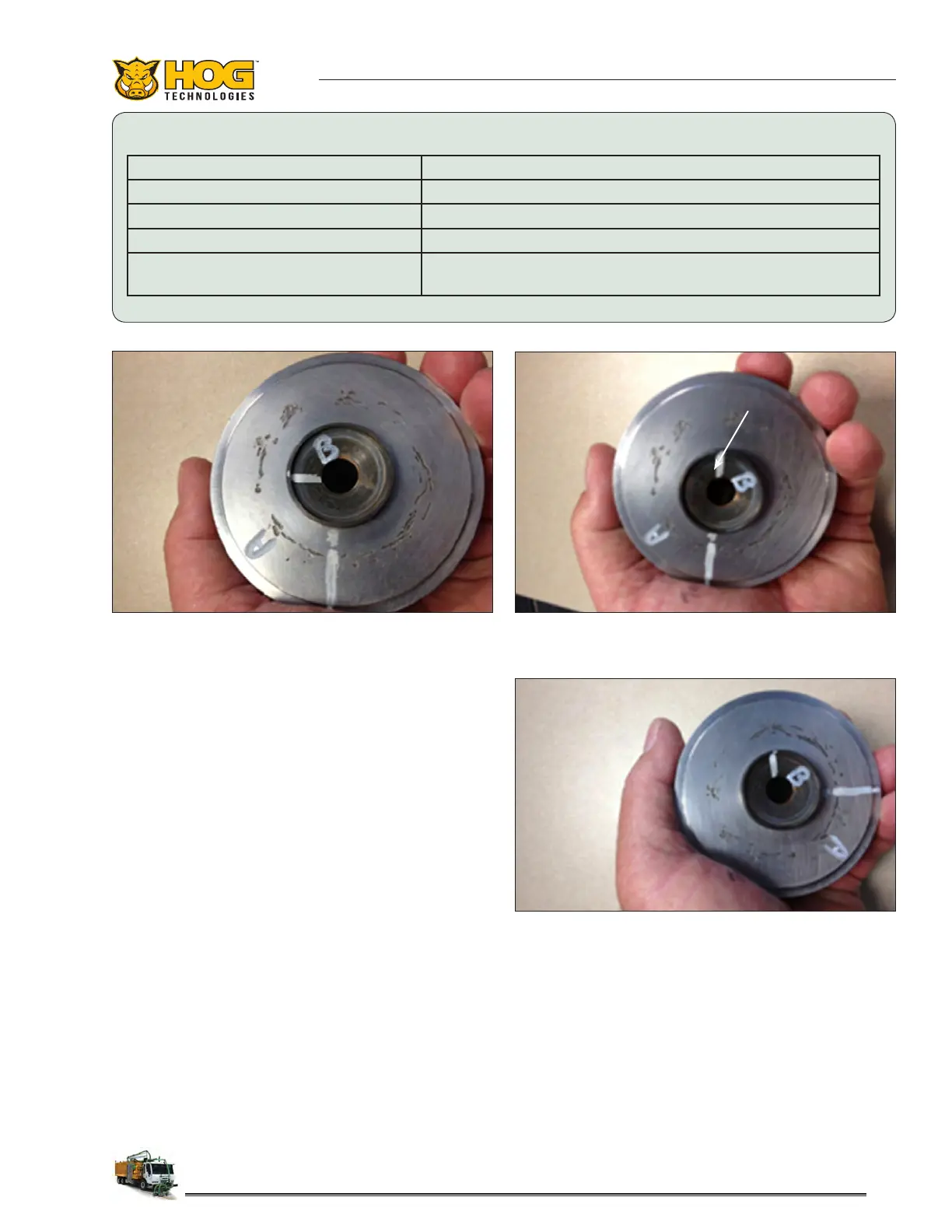

Figure 2: A. Univalve Body - B. Suction Valve

Valve Cartridge Rotated 90

0

Counterclockwise

Figure 4: A. Univalve Body - B. Suction Valve

Valve Cartridge Rotated 90

0

Clockwise

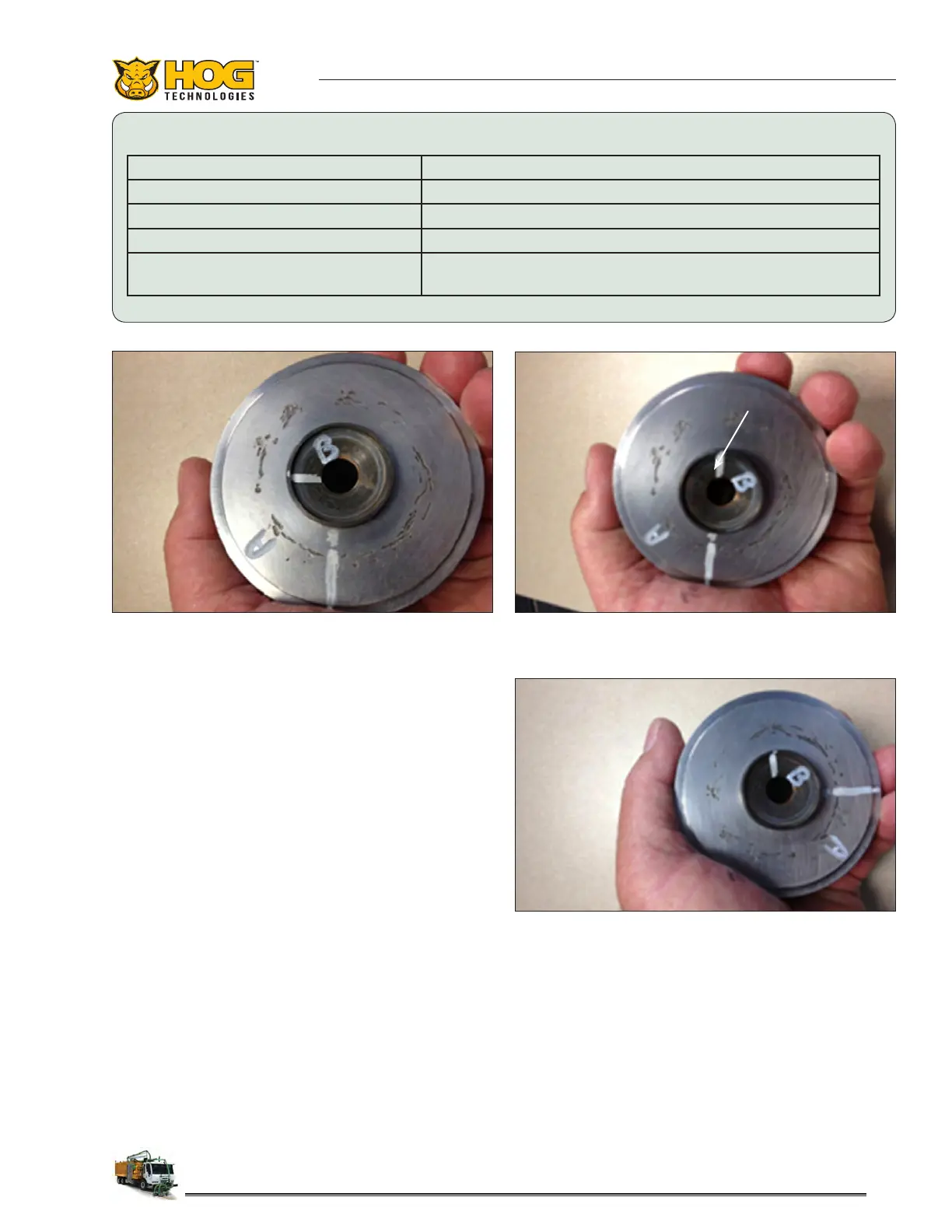

Figure 3: A. Univalve Body - B. Suction Valve

Suction Valve Rotated 90

0

Clockwise

Shiny Line Indicates a cut or a crack

Cuts caused by a leak Can be lapped if not too deep

Cracks in the univalve Cannot be repaired, replace the univalve

Shiny dot is a pit caused by calcium Can be lapped out

“V” shape on top of a hole Can be lapped out, check the inner wall of the univalve

for damage

LEGEND

6. Use approximately 5 lbs of pressure on the

suction valve (B), and rotate it 180 degrees

clockwise, then 180 degrees counterclockwise

on the valve cartridge seat (A).

7. Each 180 degree clockwise/180 degree coun-

terclockwise movement is considered one

rotation. Complete 5 rotations.

8. Rotate valve cartridge (A) 90 degrees coun-

terclockwise while maintaining the position

of suction valve (B). Repeat steps 6 and 7.

Figure 2.

9. Rotate suction valve (B) 90 degrees clockwise

while maintaining the position of valve car-

tridge (A). Repeat 6 and 7. Figure 3.

10. Rotate valve cartridge (A) 90 degrees coun-

terclockwise while maintaining the position

of suction valve (B). Repeat steps 6 and 7.

Figure 4.

11. Continue steps 6-9 for 2 minutes at about 120

rotations per minute.

12. Remove the suction valve and clean both

pieces thoroughly with brake cleaner. Be sure

to thoroughly clean the holes in the UNI-VALVE

to ensure no debris can get in the new grit.

Blow o the components with compressed air

after cleaning them with brake cleaner.

Steps 3-11 = One Cycle

Loading...

Loading...