3232

Stripe Hog Systems

Refer to the Wear Brush in this section and the

Maintenance section of this manual for additional

information on adjusting and replacing the wear

brush.

NOTICE:

ALWAYS MAKE SURE TO CHECK THE HOG HEAD FOR

SMOOTH AND PROPER OPERATION BEFORE EACH SHIFT.

DO NOT USE EQUIPMENT THAT HAS NOT BEEN CHECKED

THOROUGHLY.

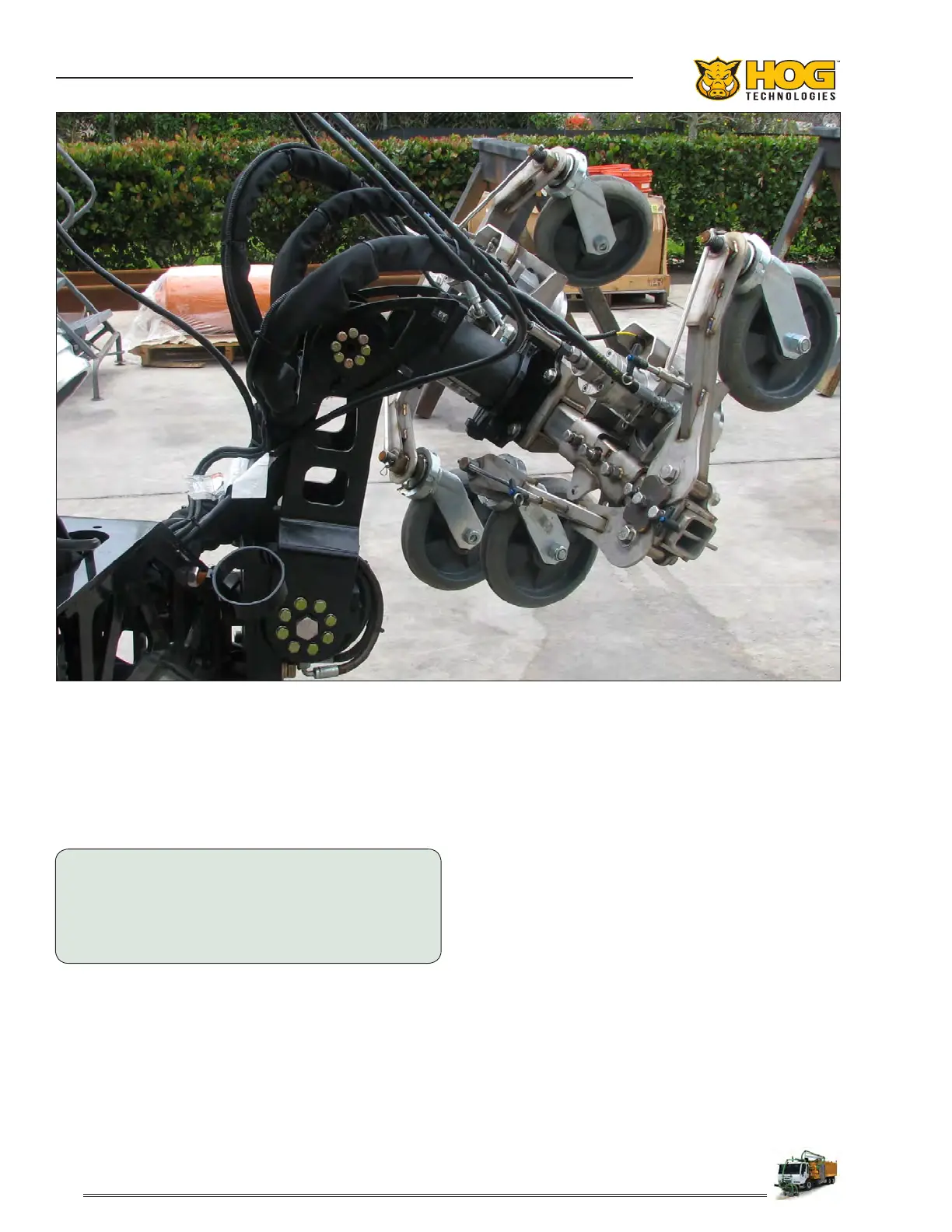

The exible design of the tubular head plate al-

lows the operator to congure the blasting heads

in a variety of congurations to accommodate

dierent waterblasting operations. The heads can

mounted together on either side of the arm or

one blasting head on each side of the arm. The

distance between the blasting heads or from the

helac cylinder to the blasting head is also adjust-

able. Special brackets with jam bolts and nuts

secure the spray heads and other tubular head

plate components in the desired position.

The blasting heads operate simultaneously when

activated by the UHP system and the start button

in joystick console. The spray bars are rotated by

special hydraulic powered motors called thru-shaft

motors. The center of the rotating shaft is drilled

to allow high pressure water to pass through the

shaft to the spray bar. Spray bar rotation is con-

trolled by the PLC (Programmable Logic Controller)

and the Head Rotation speed dial on the joystick

console.

Spray bar rotation in each blasting head can be

independently controlled by the PLC, which allows

the operator to choose various speeds between

700 and 3000 RPM or simultaneously controlled

using the Head Rotation speed dial. Two operating

Tubular Head Plate, Castor Wheels & Arms

Loading...

Loading...