5454

Stripe Hog Systems

You can avoid overow of material in the debris

bag by monitoring the water level and dumping

the recovered water when ¾ full or when you have

downtime. The debris bag should be checked at

the beginning of the shift as part of the pre-start

procedure or when you believe it may be reaching

its capacity. It should also be checked at the end

of each shift. Debris should never be left inside the

debris tank for a period of more than two days.

Debris will harden and conform to the shape of

the tank walls making it very dicult to dump.

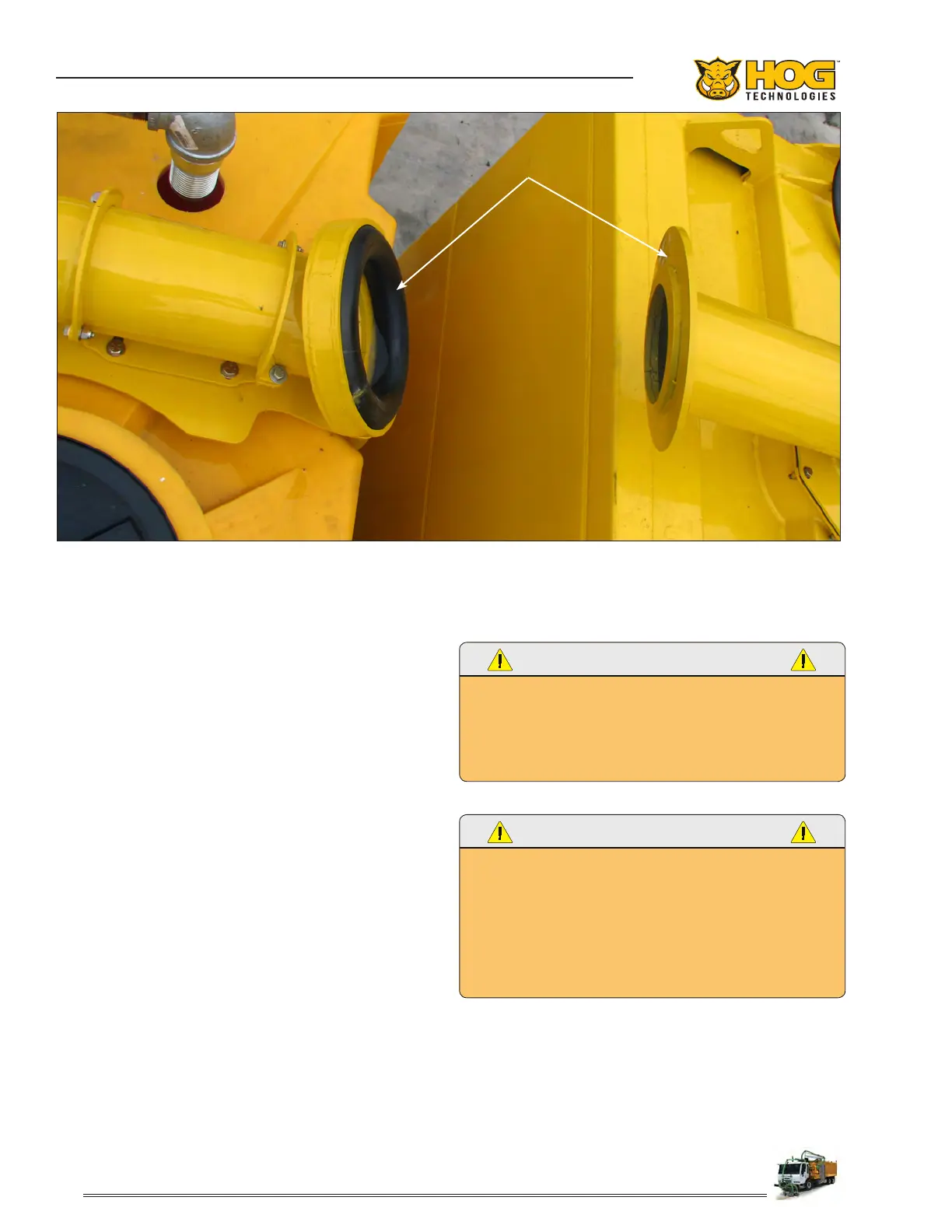

Once dumping operations are complete it is criti-

cal that the door seal and it’s point of contact be

cleaned to maintain a water tight seal during op-

erations. The O-ring seal and point of contact on

the primary vacuum tube on top of the debris tank

must also be cleaned before the tank is lowered

to the full down position. Also make sure all drain

valves are closed before resuming waterblasting

operations.

Always comply with local guidelines and state law

when dumping recovered water and debris.

Vacuum Tube Coupler O-ring & Point OF Contact At the Top of the Debris Tank

IF A DEBRIS BAG IS USED AND NOT INSTALLED CORRECTLY

IT MAY NOT RELEASE PROPERLY DURING DUMPING THIS

COULD CAUSE THE LINER TO SEPARATE FROM THE DEBRIS

TANK, DAMAGING THE TANK AND/OR CAUSING PERSONAL

INJURY.

ALWAYS MAKE SURE THAT ALL PERSONNEL ARE WELL

CLEAR OF THE TRUCK AND THE DEBRIS TANK DOOR WHEN

DUMPING OPERATIONS ARE IN PROCESS. NEVER ROCK

OR JERK THE TRUCK BACK AND FORTH TO DISLODGE

MATERIAL STUCK IN THE DEBRIS TANK. THIS CAN CAUSE

THE HYDRAULIC RAM AND/OR OTHER COMPONENTS

TO FAIL WHICH COULD RESULT IN SEVERE INJURY TO

PERSONNEL AND SEVERE DAMAGE TO THE UNIT.

Loading...

Loading...