1-3

Service Information

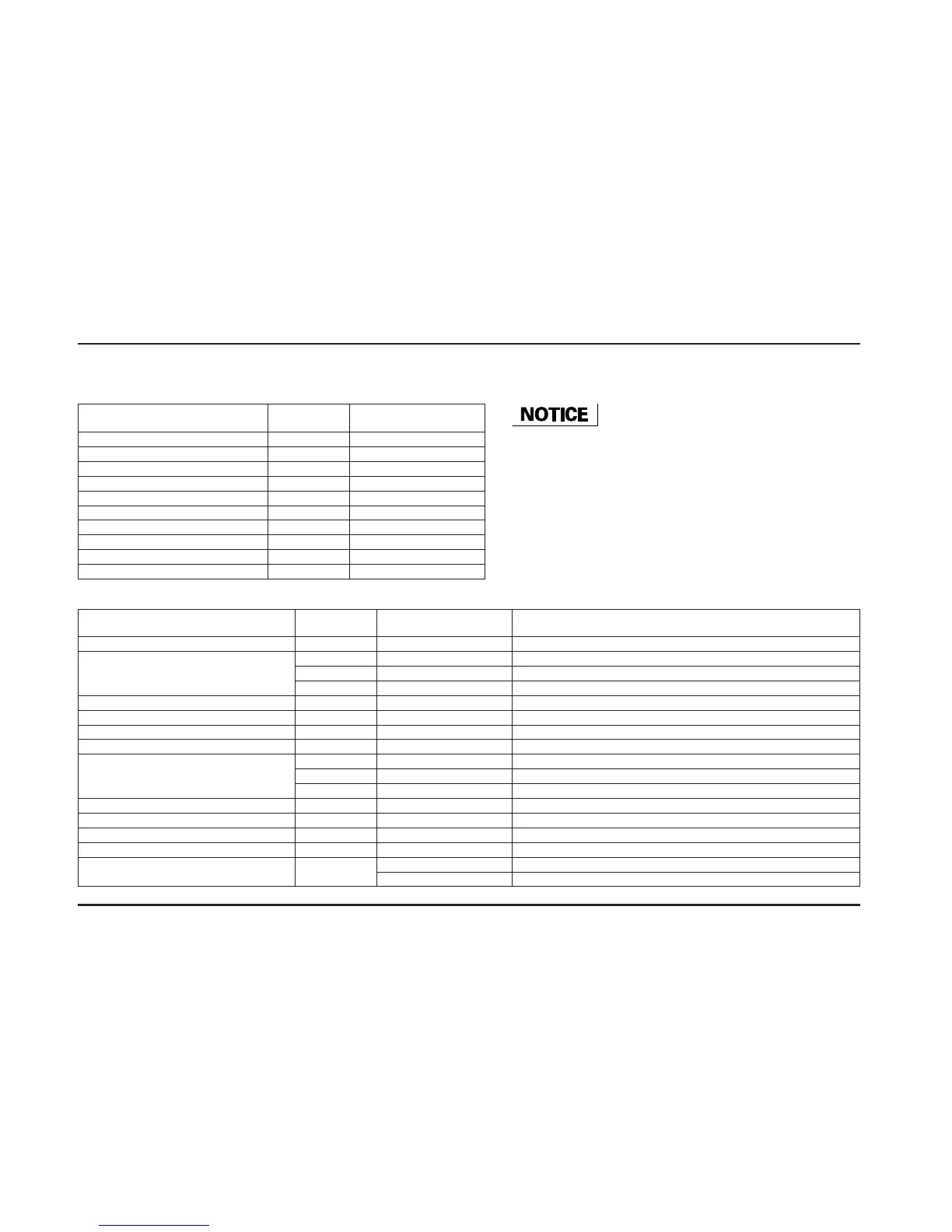

Item

Thread/ Torque

Remarks

pitch N•m (kgf•m, lbf•ft)

Main journal bolt M8 x 1.25 15 (1.5, 11) + 120˚ Apply oil to the threads and seating surface

Crankcase bolt M10 x 1.25 39 (4.0, 29) Apply oil to the threads and seating surface

M8 x 1.25 24 (2.4, 17)

M6 x 1.0 12 (1.2, 9) Apply oil to the threads and seating surface

Lower crankcase sealing bolt M20 x 1.0 30 (3.1, 22) Apply locking agent

Oil drain bolt M12 x 1.5 30 (3.1, 22) Wire lock

Timing hole cap M45 x 1.5 18 (1.8, 13) Apply grease

ACG wire clamp flange bolt M6 x 1.0 12 (1.2, 9) CT bolt (standard), SH bolt 6 x 16 (racing kit)

Cylinder head bolt M9 x 1.25 47 (4.8, 35)

Apply oil to the threads and seating surface after removing anti-rust additive

M6 x 1.0 12 (1.2, 9)

Apply oil to the threads and seating surface after removing anti-rust additive

M14 x 1.0 18 (1.8, 13) Apply locking agent

Camshaft holder bolt M6 x 1.0 12 (1.2, 9) Apply oil to the threads and seating surface

Cylinder head cover bolt M6 x 1.0 10 (1.0, 7) Apply oil to the threads and seating surface

Breather plate bolt M6 x 1.0 12 (1.2, 9) Apply locking agent

PAIR reed valve cover bolt M6 x 1.0 12 (1.2, 9) CT bolt, apply locking agent

Connecting rod bolt

M7 x 0.75

20 (2.0, 14) + 90˚ New bolt, apply oil to the threads and seating surface

14 (1.4, 10) + 90˚ Only when checking oil clearance (see above for final torque)

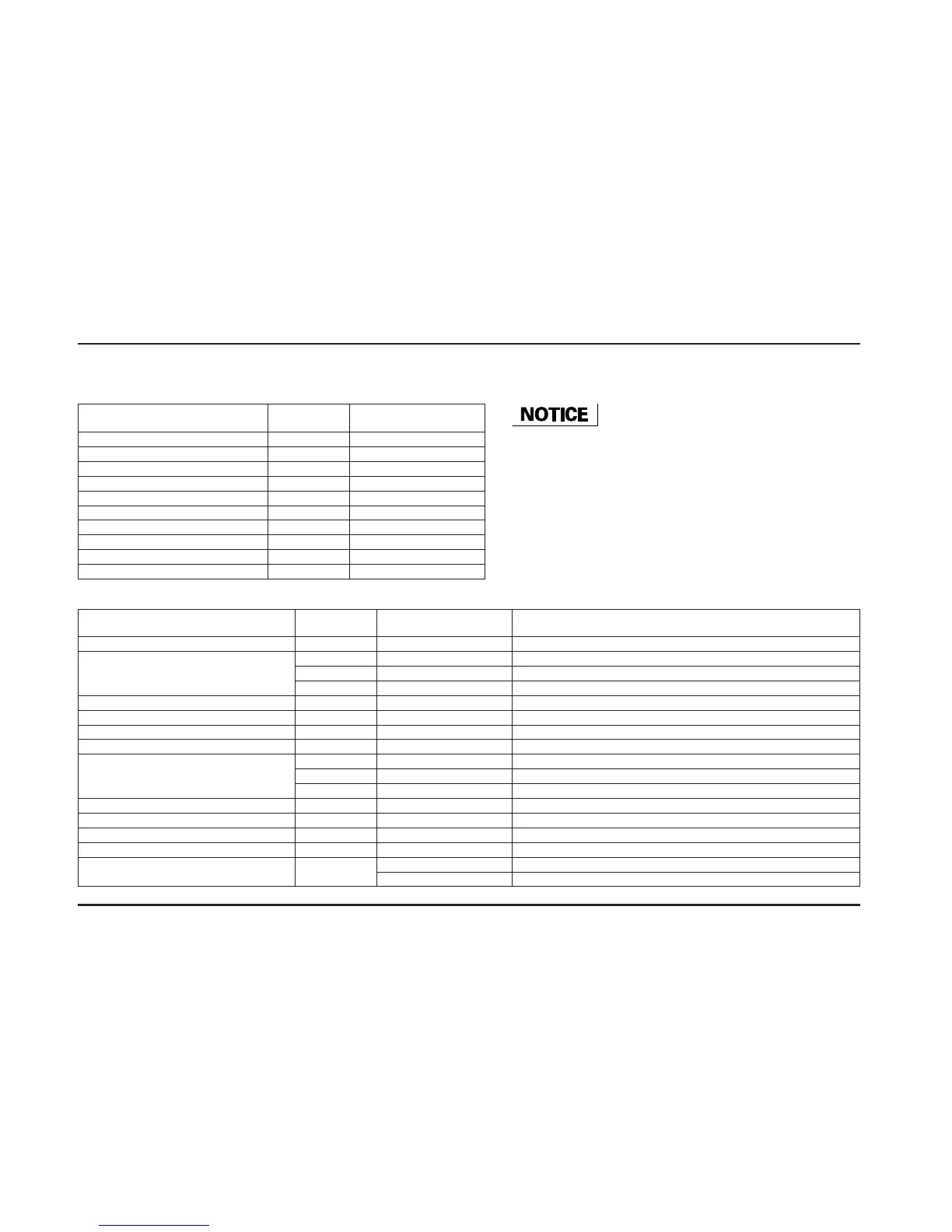

Torque Values

Standard Torque

Item

Thread/ Torque

pitch N•m (kgf•m, lbf•ft)

M5 bolt and nut M5 x 0.8 4.9 (0.5, 3.6)

M6 hex/SH bolt and nut M6 x 1.0 12 (1.2, 9)

M8 bolt and nut M8 x 1.25 22 (2.2, 16)

M10 bolt and nut M10 x 1.25 34 (3.5, 25)

M12 bolt and nut M12 x 1.25 54 (5.5, 40)

M5 screw M5 x 0.8 4 (0.4, 2.9)

M6 screw M6 x 1.0 9 (0.9, 6.5)

M6 flange bolt and nut (NSHF) M6 x 1.0 12 (1.2, 9)

M8 flange bolt and nut M8 x 1.25 26 (2.7, 20)

M10 flange bolt and nut M10 x 1.25 39 (4.0, 29)

Engine

• Use Honda 4-stroke oil on the specified bolts and nuts. Inaccurate

torque or cross threading may occur if the specified oil is not used.

• Check the crankcase cover bolt seating surfaces before tightening the

cover bolts. If the crankcase cover painting peels off, remove paint

from the bolt seating surfaces, then tighten the bolts.

Loading...

Loading...