8.2 Routine Maintenance

To ensure that the SUN2000 can operate properly for a long term, you are advised

to perform routine maintenance on it as described in this chapter.

Before cleaning the system, connecting cables, and ensuring the grounding

reliability, power o the system.

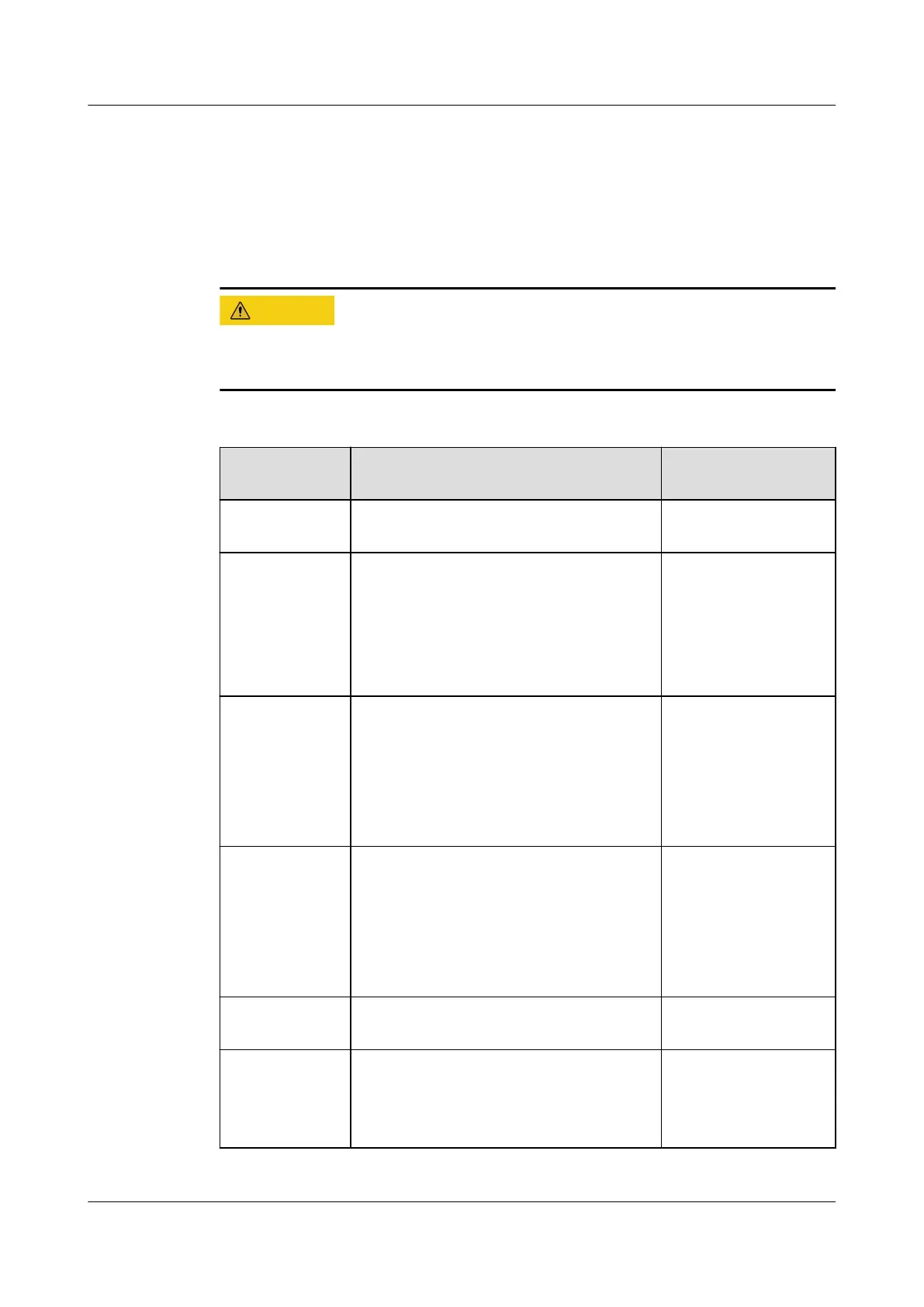

Table 8-1 Maintenance checklist

Check Item Check Method Maintenance

Interval

System

cleanliness

Check periodically that the heat sinks

are free from obstacles and dust.

Once every 6 to 12

months

System

operating

status

● Check that the SUN2000 is not

damaged or deformed.

● Check that the SUN2000 operates

with no abnormal sound.

● Check that all SUN2000 parameters

are correctly set during operation.

Once every 6

months

Electrical

connection

● Check that cables are secured.

● Check that cables are intact, and

that in particular, the parts touching

the metallic surface are not

scratched.

The rst inspection is

6 months after the

initial

commissioning.

From then on, the

interval can be 6 to

12 months.

Grounding

reliability

Check that ground cables are securely

connected.

The rst inspection is

6 months after the

initial

commissioning.

From then on, the

interval can be 6 to

12 months.

Air tightness Check that all terminals and ports are

properly sealed.

Once a year

Clear

vegetation

around the

inverters

● Perform inspection and weeding as

required.

● Clean the site promptly after

weeding.

Based on the local

wilting season

SUN2000-(20KTL, 29.9KTL, 30KTL, 36KTL, 40KTL)-

M3

User Manual 8 Maintenance

Issue 11 (2023-01-10) Copyright © Huawei Technologies Co., Ltd. 73

Loading...

Loading...