English - 54

5 Repair instructions

All repairs to robotic lawnmowers should be done in-

doors on a clean work bench to protect sensitive compo-

nents from moisture and dirt.

All screws in the robotic lawnmower must be tted using

the correct tightening torque according to Table 3: Screw

Fasteners on page 82.

Oil, grease and dirt on electrical

connections can cause intermittent

faults on the robotic lawnmower. These

faults only occur at times, which make

them difcult to nd. Never touch

sensitive electronic components with

your ngers, for example, connectors or

components on a circuit board.

To avoid electrostatic discharge in

electronic components always earth

yourself, for example against a radiator,

before you start to work on electrical

components.

Always disconnect cables from a

component by pulling the connector. Do

not pull the actual cable.

Never use any form of silicone or the like

when repairing a robotic lawnmower.

If possible test that components work

before completely assembling the

robotic lawnmower.

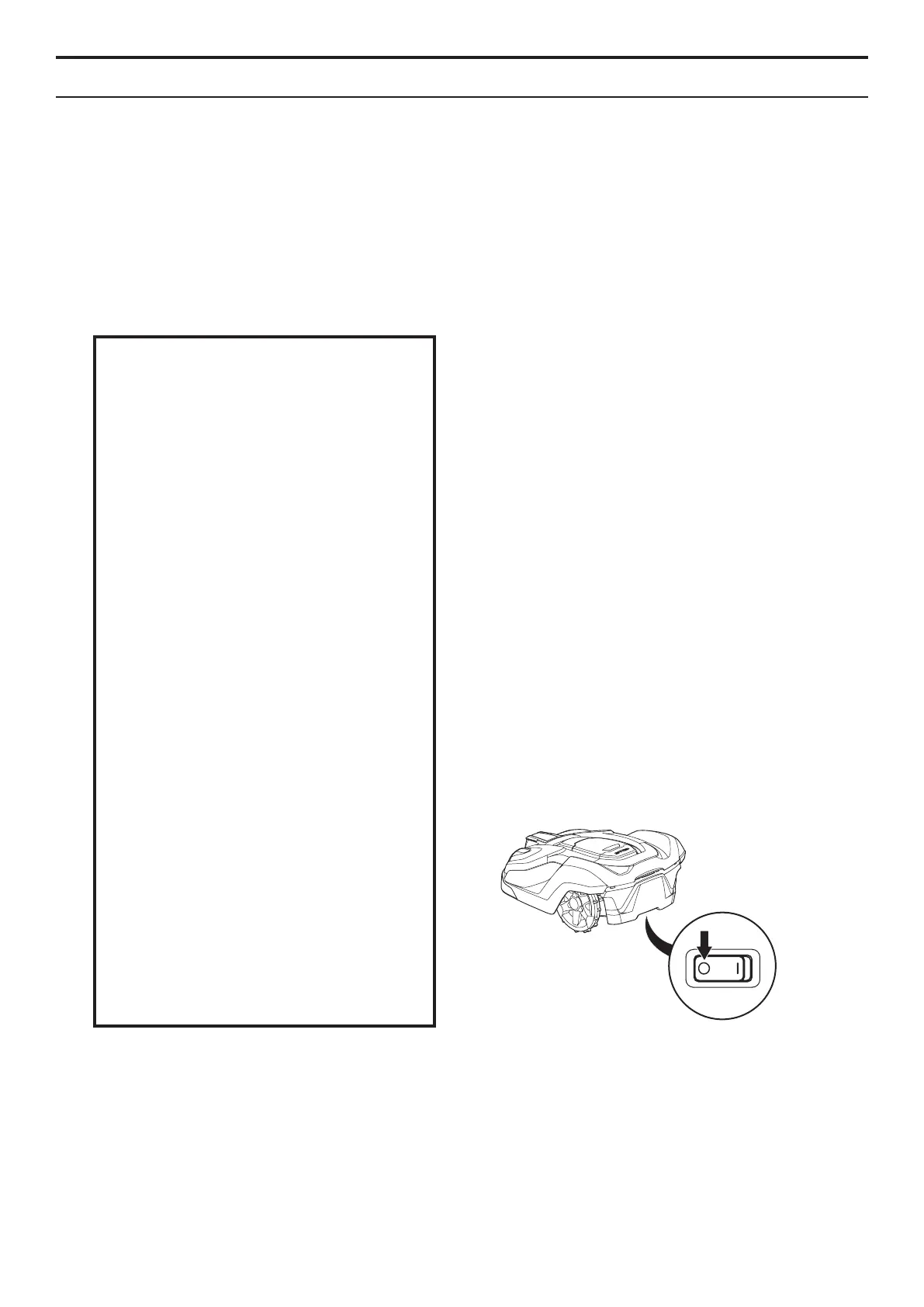

Always set the mower's main switch to

0 before connecting or disconnecting

any connectors (for example HMI cable

to main circuit board). If the main switch

is left in position 1, there is a risk the

circuit board will be destroyed when

connecting.

IMPORTANT INFORMATION

5. REPAIR INSTRUCTIONS

Loading...

Loading...