5 I/O Interface Connections

5 - 5

a) With I/O relay board, each connection point on the board can withstand a

maximum of AC 250V and 10A current.

b) Without I/O relay board, the output transistor circuit of HUST H2N

controller is rated at a maximum of 35V and 500 mA of current.

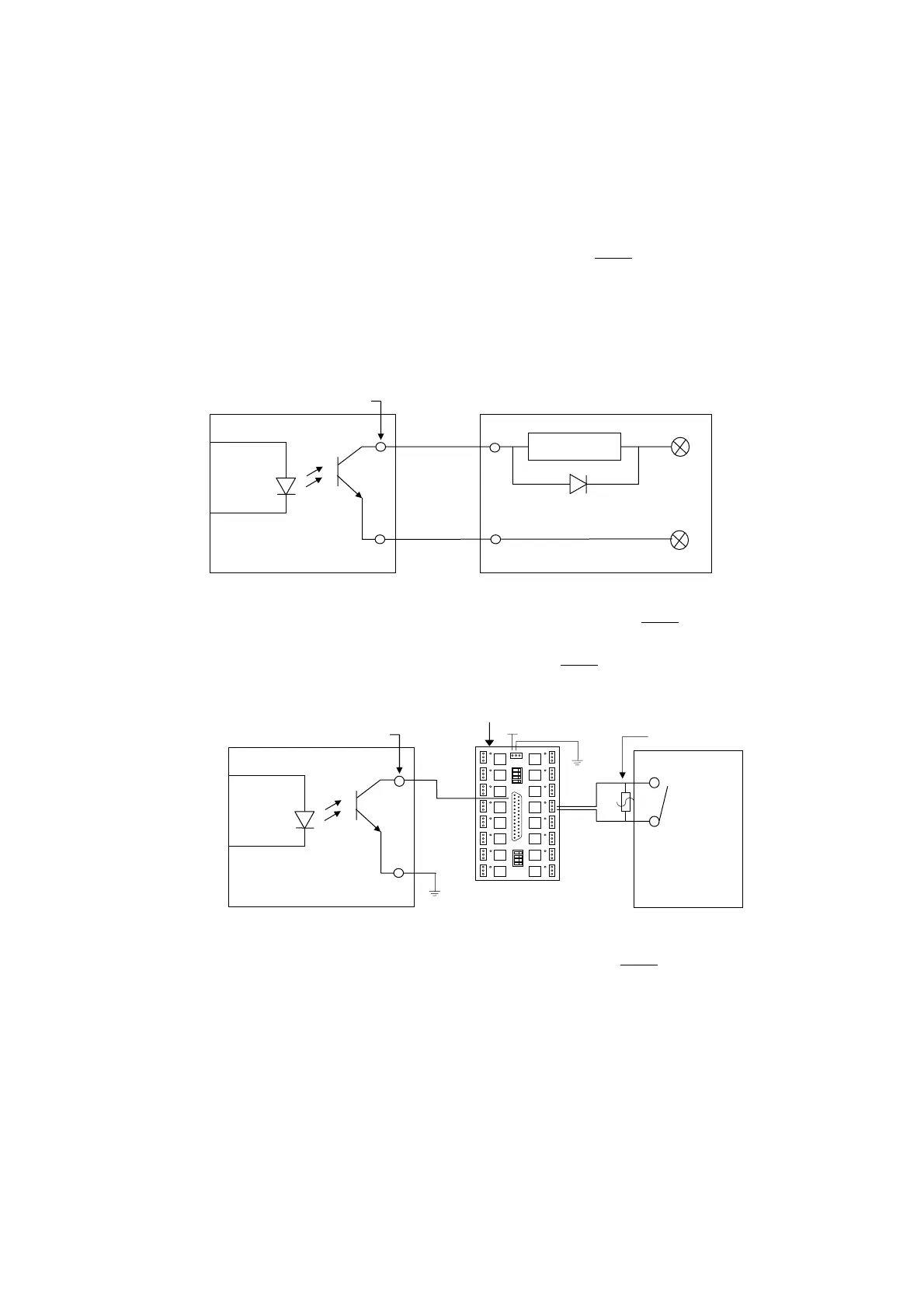

• Output Signal Directly Connected from CNC to Tool (NPN-type)

When output connector is directly connected to an inductive load, such as relay,

it must connect a spark killer diode in parallel and as close to the load as

possible. (See Fig 5-6) ll output terminal of HUST H2N controller is open

collector transistor circuit.

Fig 5-6 Output Signal from CNC without Relay Board (NPN-type)

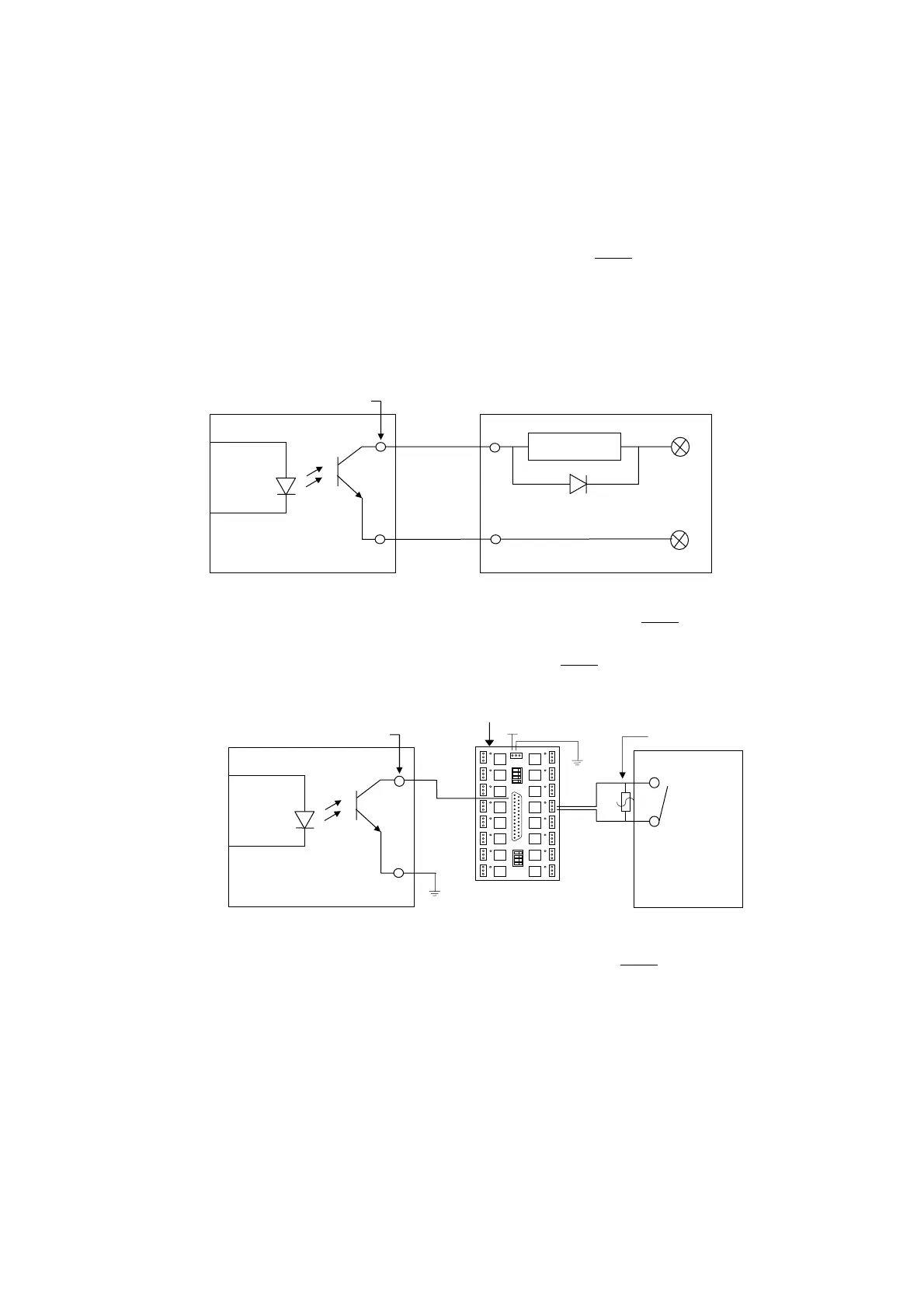

• Output Signal Connected to Output Relay Board (NPN-type)

Fig 5-7 Output Signal Connected to Relay Board (NPN-type)

5.5 Emergency-Stop Circuit

The electronic circuit in the controller requires about 100 milli-seconds to reach

stable state when power is turned on. During this unstable period, the servo motor

should not be turned on. To accomplish this purpose, HUST internal PLC has a

"Servo-on Timer" with 1.5 seconds. When the timer is up, the controller sends an O-

bit high (1) to turn on the servo driver.

RELAY

Ext. Device

Spark Killer

CNC Side

DB25LM Pin

DB25LM Output

Output Board

Spark Killer

CNC Side

0V

24V

0

O

Ext. Tool

Loading...

Loading...