6 Interface Between CNC And PLC

6 - 7

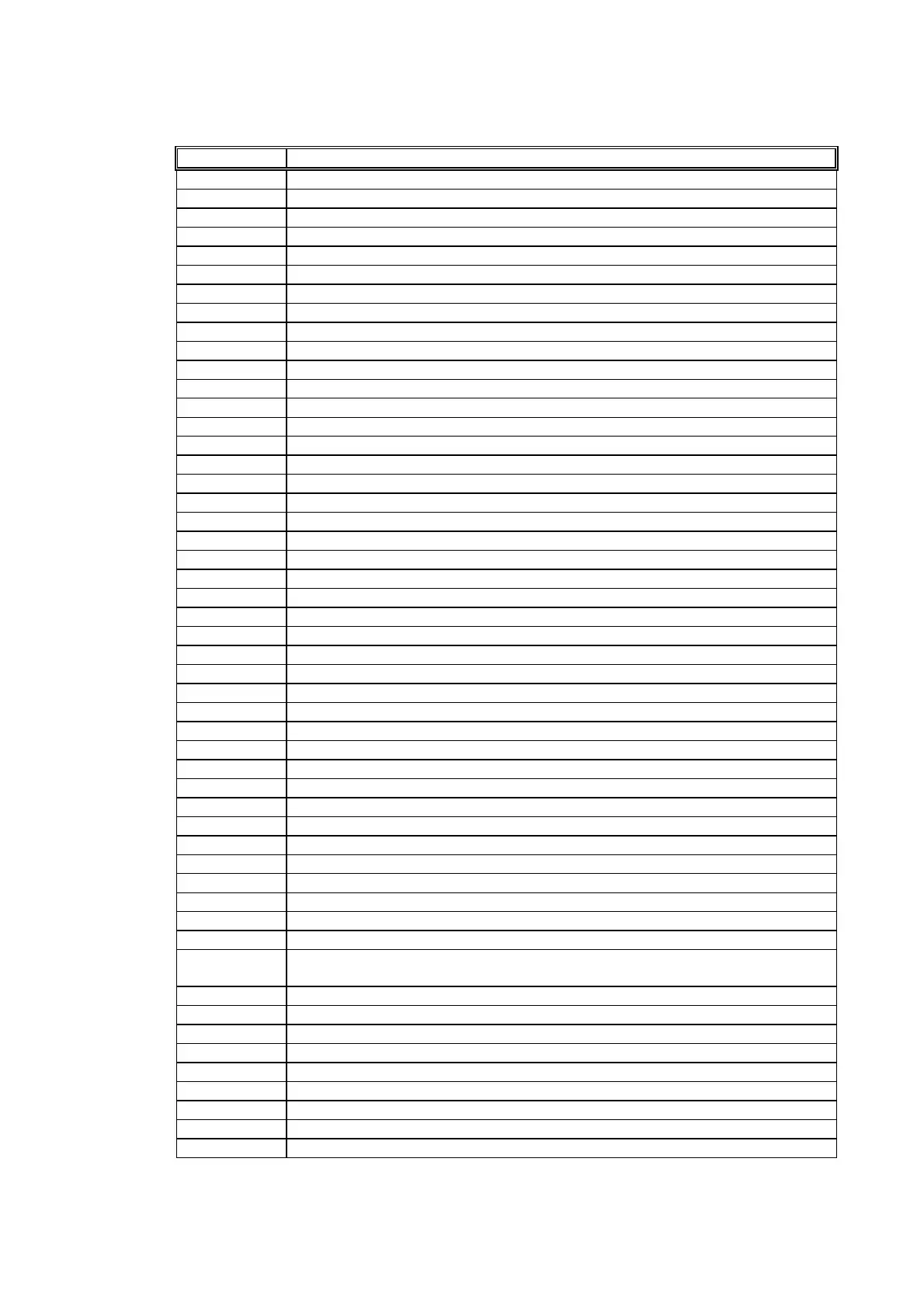

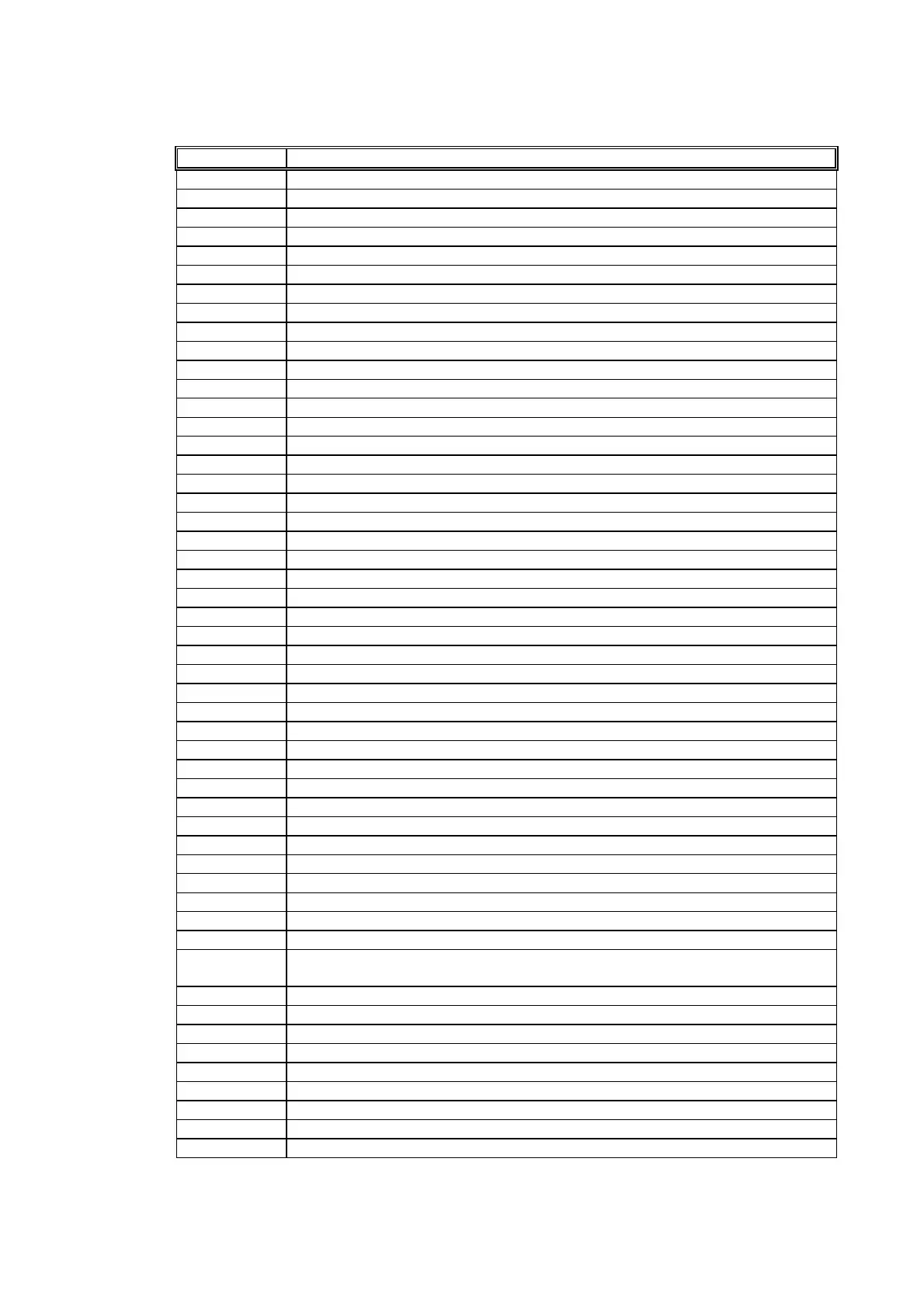

Table 6-2 C-bit Signals Description

Bit Number C-Bit Signal Description

C000 Machine Lock/Feed hold

C001 Reset

C002 Emergency stop

C003 Reserved

C004 Cycle start

C005 Program No. selection by INPUT key

C006 Single Block

C007 NC alarm & stop NC command

C008~C010 Reserved

C011 Program restart -1

C012~C013 Program restart from the previous program after jumping to other program

C014 Reserved

C015 Dryrun

C016~C019 Reserved

C020~C021 Cursor up / Cursor down command

C022~C023 Page up / Page down command

C024~C025 Reserved

C026 Option stop

C027 Option skip

C028 Speed deceleration selection for G31 Skip function

C029 Reserved

C030 Counter status (On/Off) command

C031 Ladder simulation

C032 M-code finish signal from PLC to CNC

C033 T-code finish signal from PLC to CNC

C034 S-code finish signal from PLC to CNC

C035 Reserved

C036 Round corner non-stop operation

C037~C055 Reserved

C056 MPG hand-wheel test mode

C057 Return to the last program block where execution was interrupted

C058 Program EDIT mode disabled

C059 MCM EDIT mode disabled

C060~C062 Reserved

C063 HOME execution command

C064~C065 HOME limit switch signal for X, Y-axis

C066~C079 Reserved

C080~C081 Set X, Y-axis work coordinate system

C082~C095 Reserved

C096~C097 Clear X, Y-axis program & machine coordinate to zero (0)

C098~C116 Reserved

C117 C117=0, Open loop circuit for spindle

C117=1, Closed loop circuit for spindle

C118~C119 Reserved

C120 Command code for program selection from external device

C121 Command code for spindle speed control (in %) from external I/O device

C122 Reserved

C123 Set work coordinate system (G54~G59)

C124 Reserved

C125 M, T, and S-code to be executed in synchronization

C126~C127 Reserved

C128~C129 To enable axial data input (X, Y) when in TEACH mode

Loading...

Loading...