6 Interface Between CNC And PLC

6 - 25

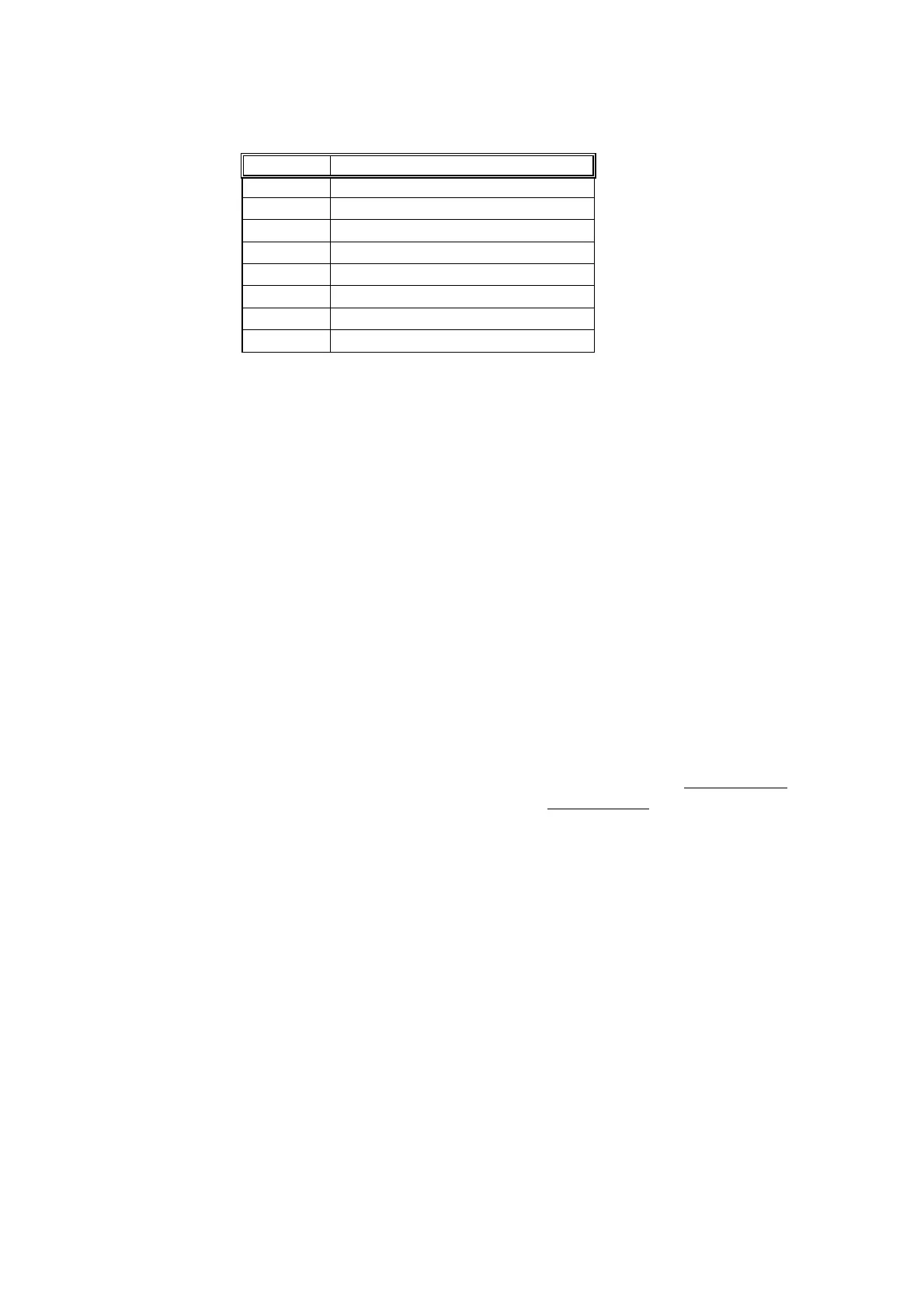

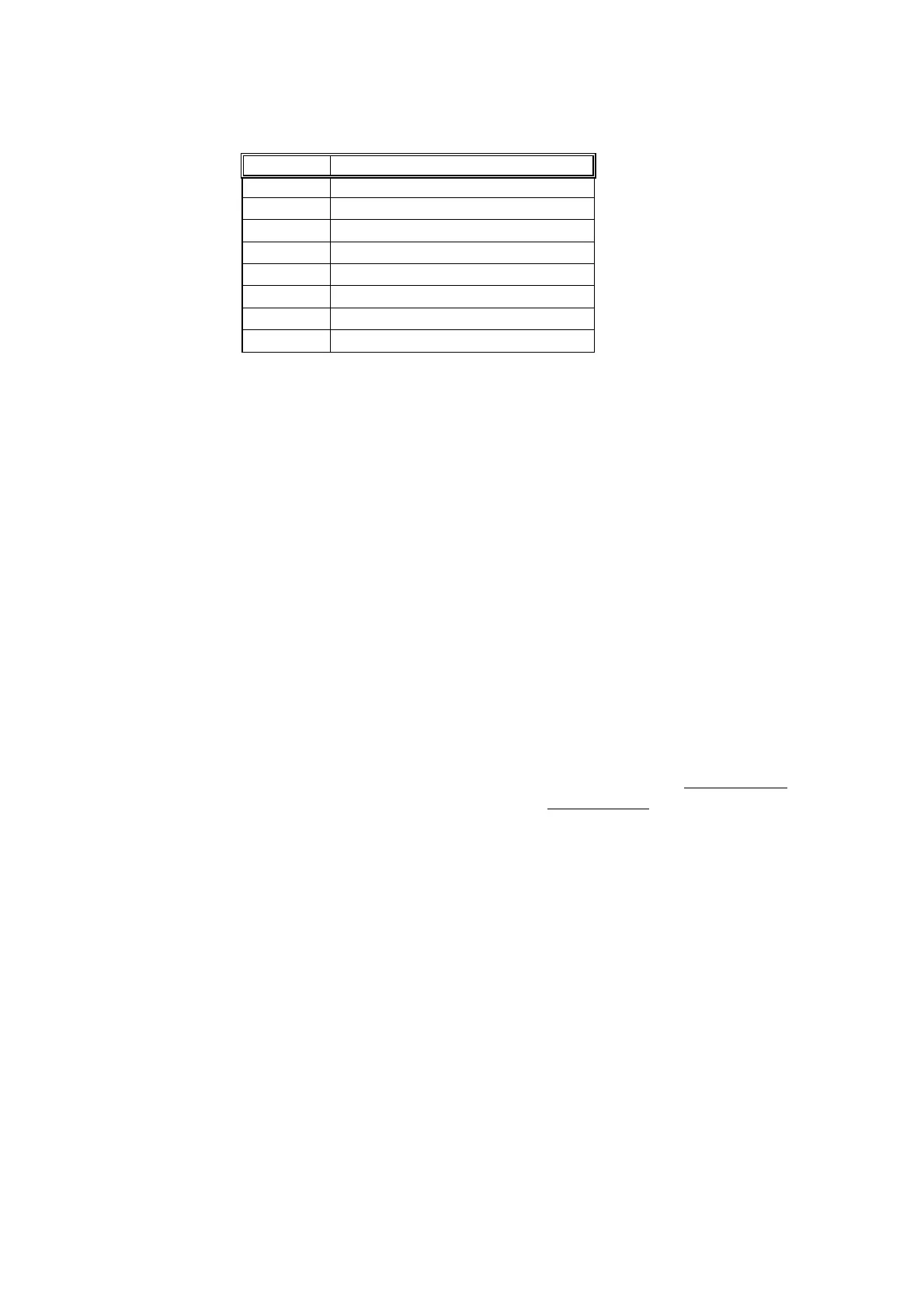

R100, Execution mode selection according to table below

R100

0 NONE

1 AUTO

2 HOME

3 EDIT

4 JOG

5 TAPE

6 TEACH

7 MDI

R160~R161, Feed-rate setting for X and Y-axis

R180~R181, Absolute coordinate setting for X and Y-axis

These registers are for positioning in PLC and are used with C208~C209. The

coordinates R180~R181 will be multiplied by 10 and their maximum setting

values are 32767.

When C208 = 0→1, X-axis moves to the position of R180*10 with a speed of R160.

While executing, S208=1 and S208=0 when execution completed.

When C209 = 0→1, Y-axis moves to the position of R181*10 with a speed of R161.

While executing, S209=1 and S209=0 when execution completed.

Ex: R180 = 1000, R160 = 2500.

When C208 = 0→1, X-axis moves to the location of 10.000

(R180*10=10000) with a speed of 2500 mm/min.

R190, Type of motor deceleration selection for G31 skip function

R190 is used in conjunction with C028.

C028 = 0 (low), servo motor ignores the value in R190 and decelerates linearly to zero

.

C028 = 1 (high) & R190 = 0, servo motor speed jumps to zero

.

C028 = 1 (high) & R190 ≠0, servo motor will stop in a distance = value in R190.

R200, Page number for liquid LCD screen display

R200 = 0, Standard system display

R200 = 1~63, Page number for user designed LCD screen display

R220, Setting feed-rate percentage for G00 MFO %

Default = 100 (%), range 0 ~ 100.

For example, if program G00 feed-rate = 3000 and R220 = 80, the actual G00

feed-rate output = 2400.

R221, Setting feed-rate percentage for G01, G02, G03 MFO %

Loading...

Loading...