HUST H2N Connecting Manual

9 - 4

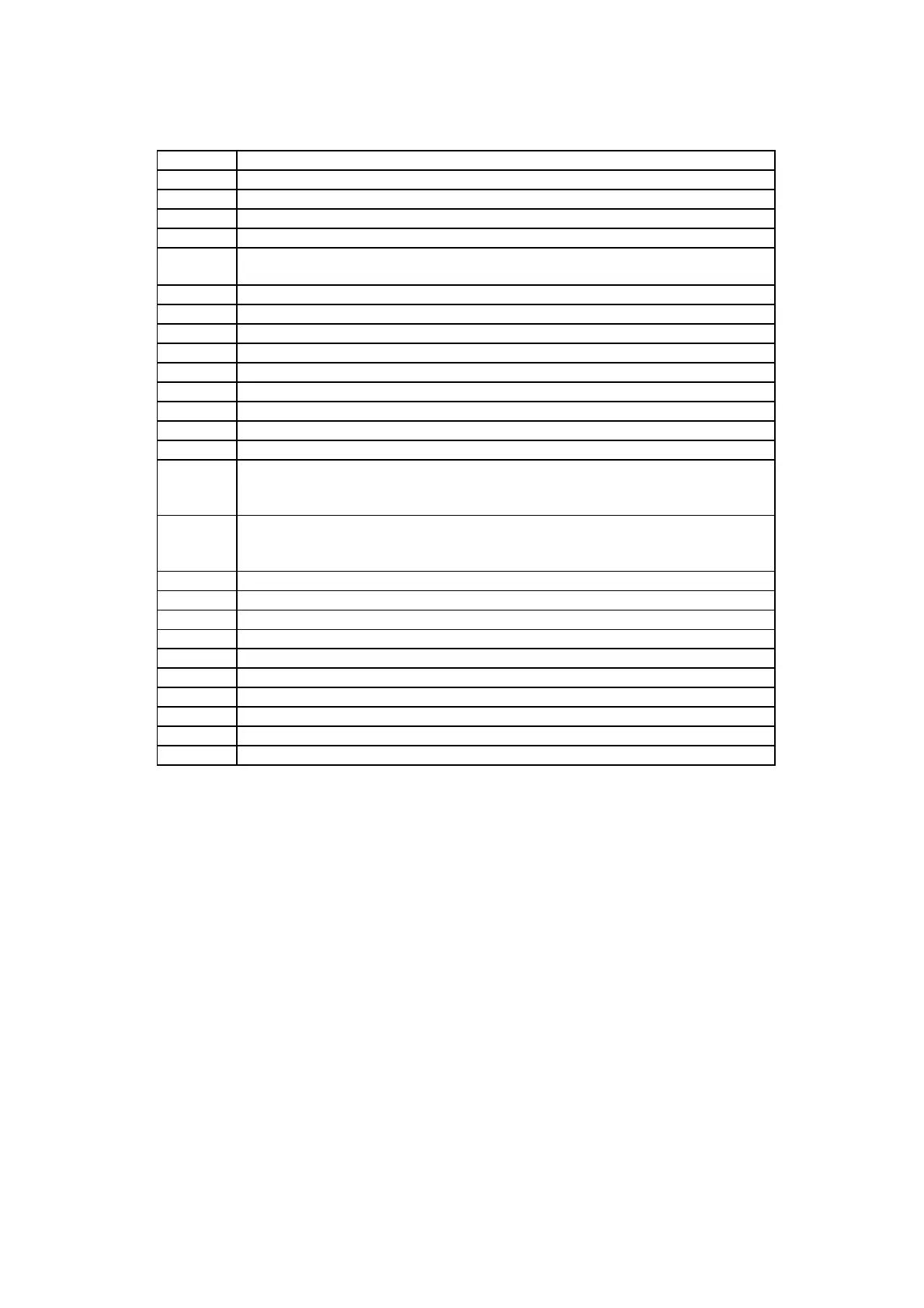

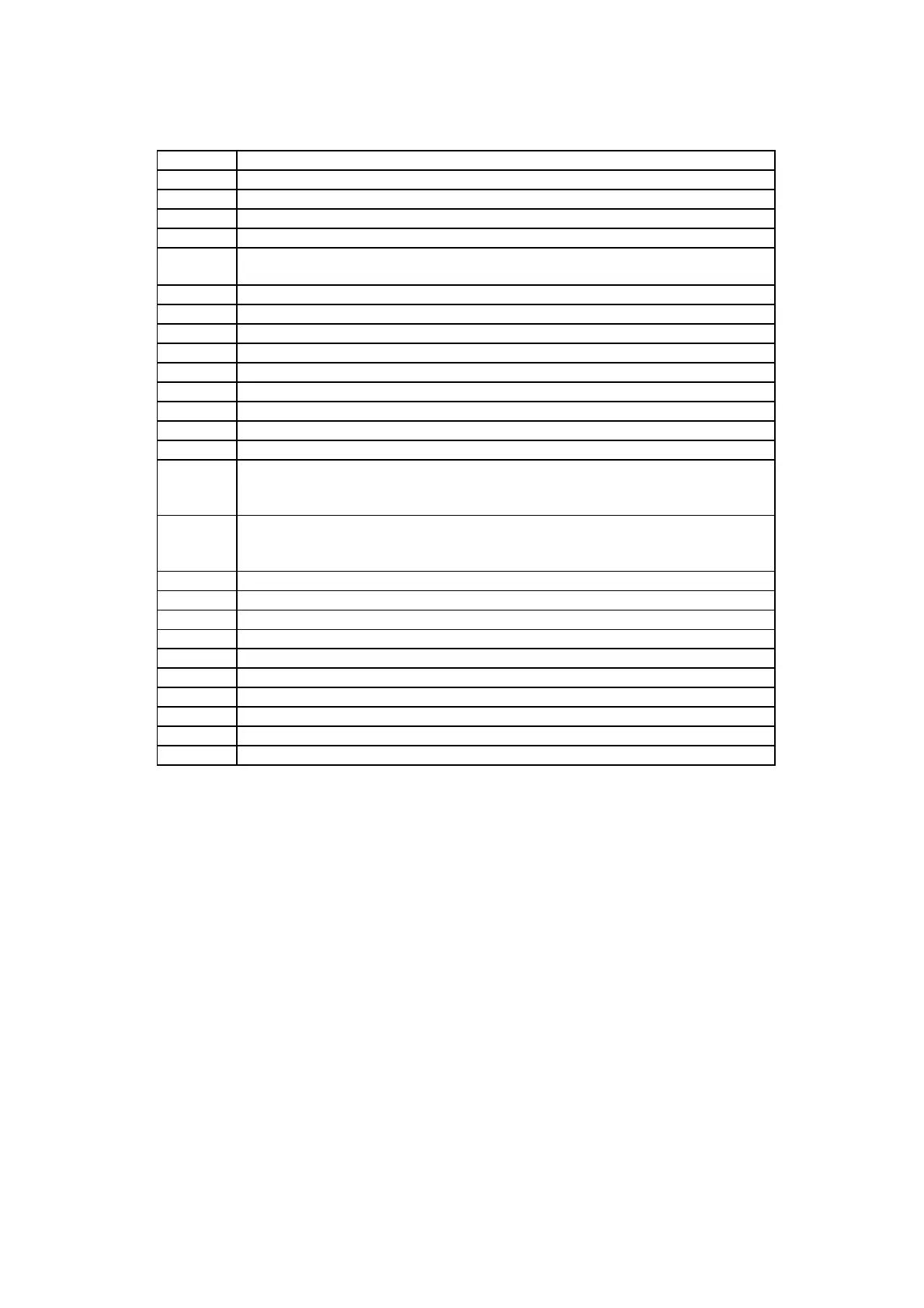

Table A2 Meaning of Command Format Representation

Item No Meaning of Command Representation

1 Stop report

2 RESET control

3 AUTO mode

4 SINGLE mode

5 MDI mode. Input MDI data to controller. The MDI data is typed in the next line as

"Gxx X-123.45 Y123.45 F123.45 .....<CR>

6 CYCLE START

7 Current program position during execution

8 Current machine position

9 Tool feedrate

10 Spindle speed

11 Current tool offset

12 Current block counter

13 The controller reads program from PC. Item No 1 'On' also.

14 The controller punches out program to PC. Item No 1 'On' also.

15 Select a part program. Pxxxx<CR> must be in the program also. Otherwise, this

request is invalid. This request will be ignored if the CNC controller is currently in

process or edit mode.

20 Delete part program specified by Pxxxx<CR>.

Without Pxxxx<CR>, delete the current program. This request will be ignored if the

controller is currently in process or edit mode.

21 Free memory (available for programming) report to PC

*22 File directory report from HUST CNC to PC

23 Current input-bit status (I-Bit)

24 Current output-bit status (O-Bit)

25 Current command-bit status (C-Bit)

26 Current status-bit status (S-Bit)

27 Current auxiliary-bit status (A-Bit)

28 The controller reads MCM data from PC

29 The controller Punches out MCM data to PC

*30 30 and above are reserved for future expansion.

Note: Items with '*' are not available at the moment.

Example 5 : The 14th command, CNC PUNCH OUT program to PC

DC2

%<CR>

O9000<CR>

N10000000000001<CR> ----- Bit 14 On, Punch out program to PC

%

DC4

Example 6: The 5th/6th command, Download MDI data to controller then

Execute

DC2

%<CR>

O9000<CR>

N000011<CR> ----- Bit 5,6 On, download MDI data then execute

G01 X120.0 Y123.45<CR> ----- MDI data is specified in this line

Loading...

Loading...