MAINTENANCE

5-18 HPR130 Manual Gas Instruction Manual

6

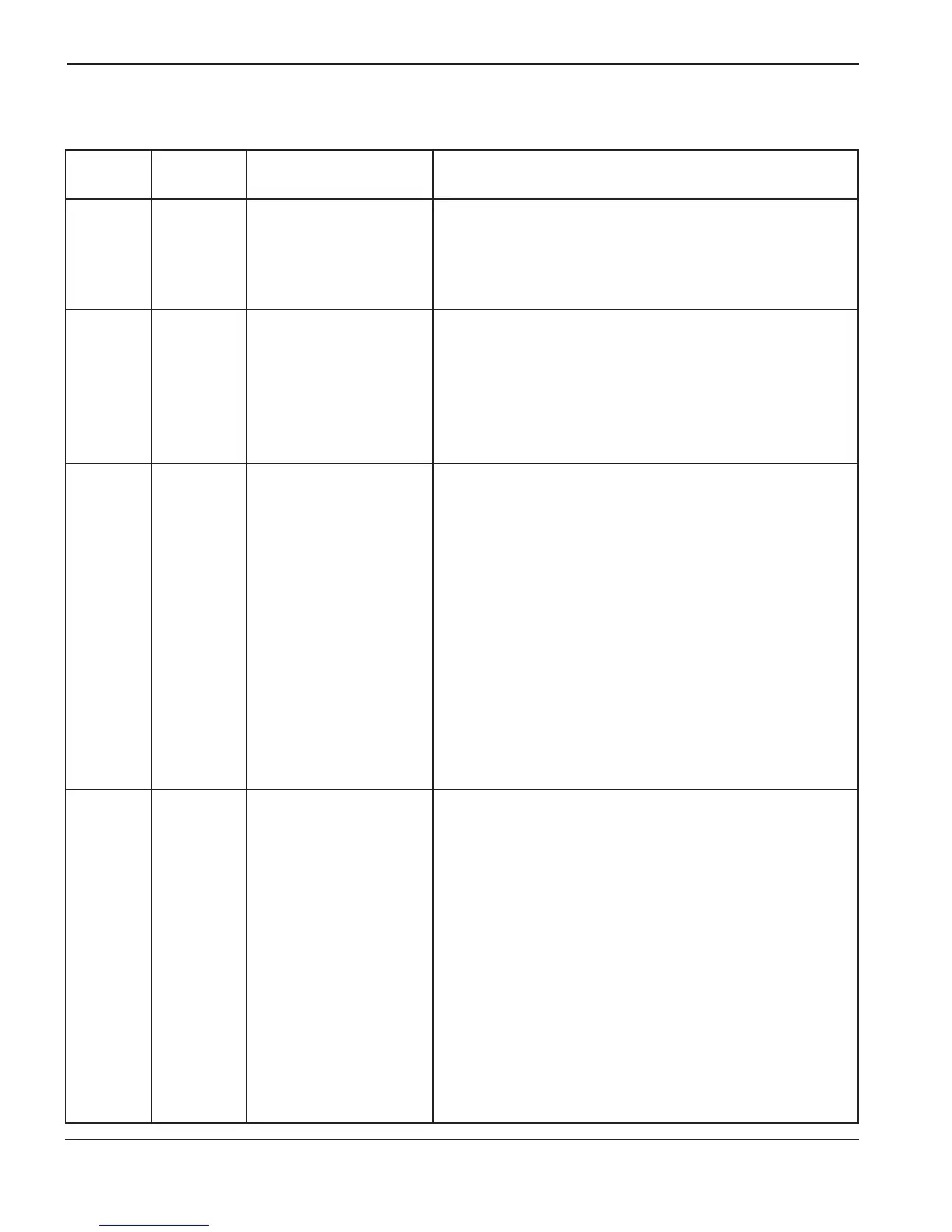

Error code troubleshooting – 8 of 10

Error code

number

Name Description Corrective action

123

MV1 error

Auto Gas

Only

Motor valve 1 did not

move into position within

60 seconds.

1. Verify that LED D17 or D18 illuminates on the AC valve

driver PCB in the selection console. If either illuminates,

replace the motor valve. If they do not illuminate, replace

PCB3.

124

MV2 error

Auto Gas

Only

Motor valve 2 did not

move into position within

60 seconds.

1. Verify that LED D19 or D20 is illuminating on the AC valve

driver PCB in the selection console. If either illuminates,

replace the motor valve. If they do not illuminate, replace

PCB3.

133

Unknown

gas console

type

The power supply control

board does not recognize

the gas console that is

installed or has not

received a CAN message.

1. Verify that the part numbers of PCB2 and PCB3 are correct.

2. Verify that cable number 5 (power supply-to-gas console

control cable) is not damaged and is properly connected to

PCB3 and the rear of the gas console.

3. Verify that cable number 6 (power supply-to-gas console

power cable) is not damaged and is properly connected

inside the power supply and to the rear of the gas console.

4. Verify that D1 (+5 VDC) and D2 (+3.3 VDC) are illuminated

on PCB2 inside the gas console. These LEDs indicate

power to PCB2.

5. If power is present at PCB2 and PCB3 and both gas

console cables are good, then PCB2 or PCB3 has failed.

Use the CAN tester to verify which board needs to be

replaced.

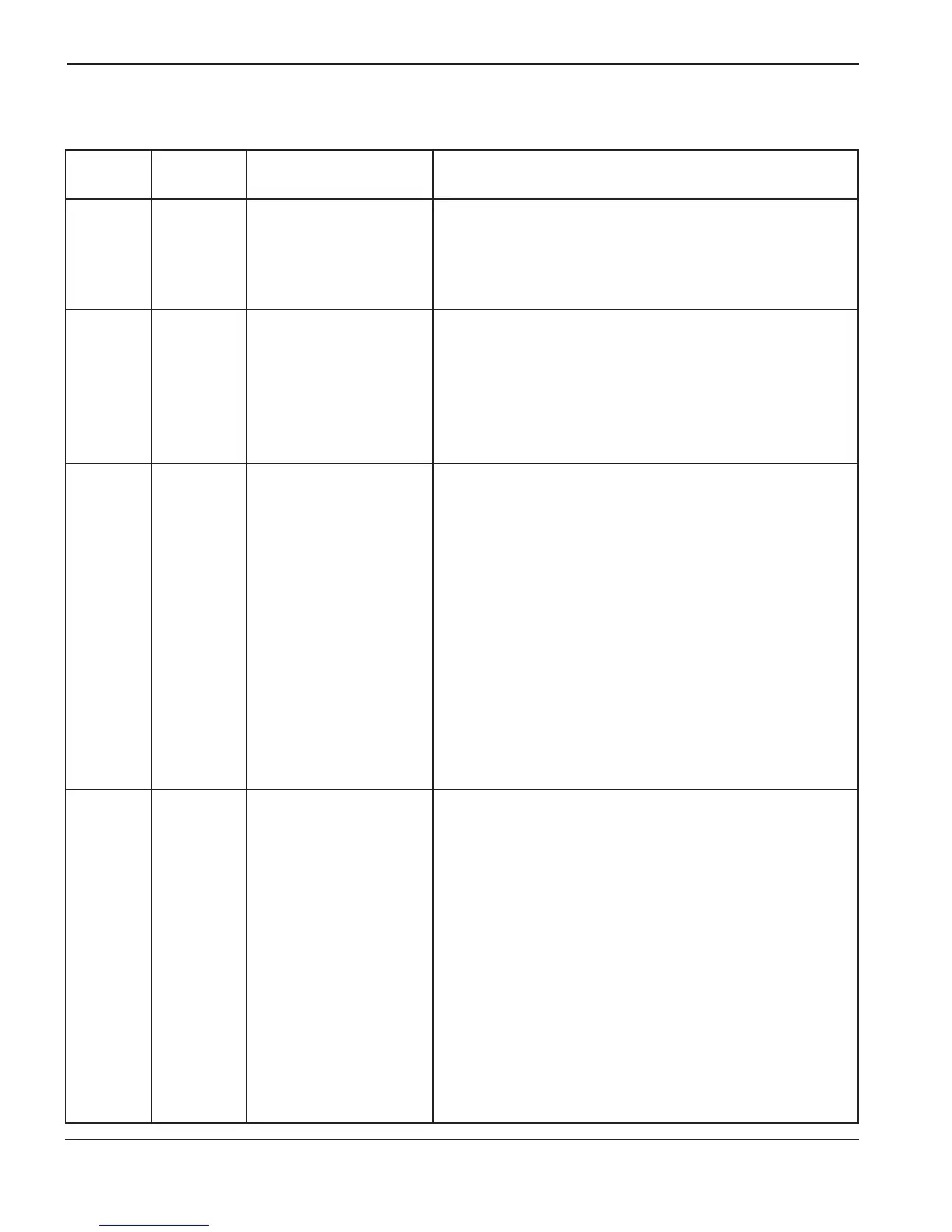

134

Chopper 1

overcurrent

Chopper 1 current

feedback has exceeded

160 amps.

1. Verify that the wiring between CS1 and PCB3 is correct

and not damaged.

2. Measure voltage across current sensor.

a) Red to black = +15 VDC, Green to black = -15 VDC,

white to black = 0 VDC at idle and varies with current

output (4 VDC = 100 amps).

b) If possible, take a voltage reading on current sensor while

trying to cut. Ratio is 4 VDC = 100 amps.

c) If the current sensor voltage is approximately 6.4 VDC or

greater at idle, replace the current sensor.

3. Remove connector J9.1 from the chopper and verify that

LED1 is extinguished.

a) If LED1 is extinguished with the connector removed, then

reconnect J9.1 and try to fire the torch. If the chopper still

goes into overcurrent, replace the chopper.

b) If the chopper does not go into overcurrent, replace

PCB3.

Loading...

Loading...