0

PARTS LIST

HPR130 Manual Gas Instruction Manual 6-3

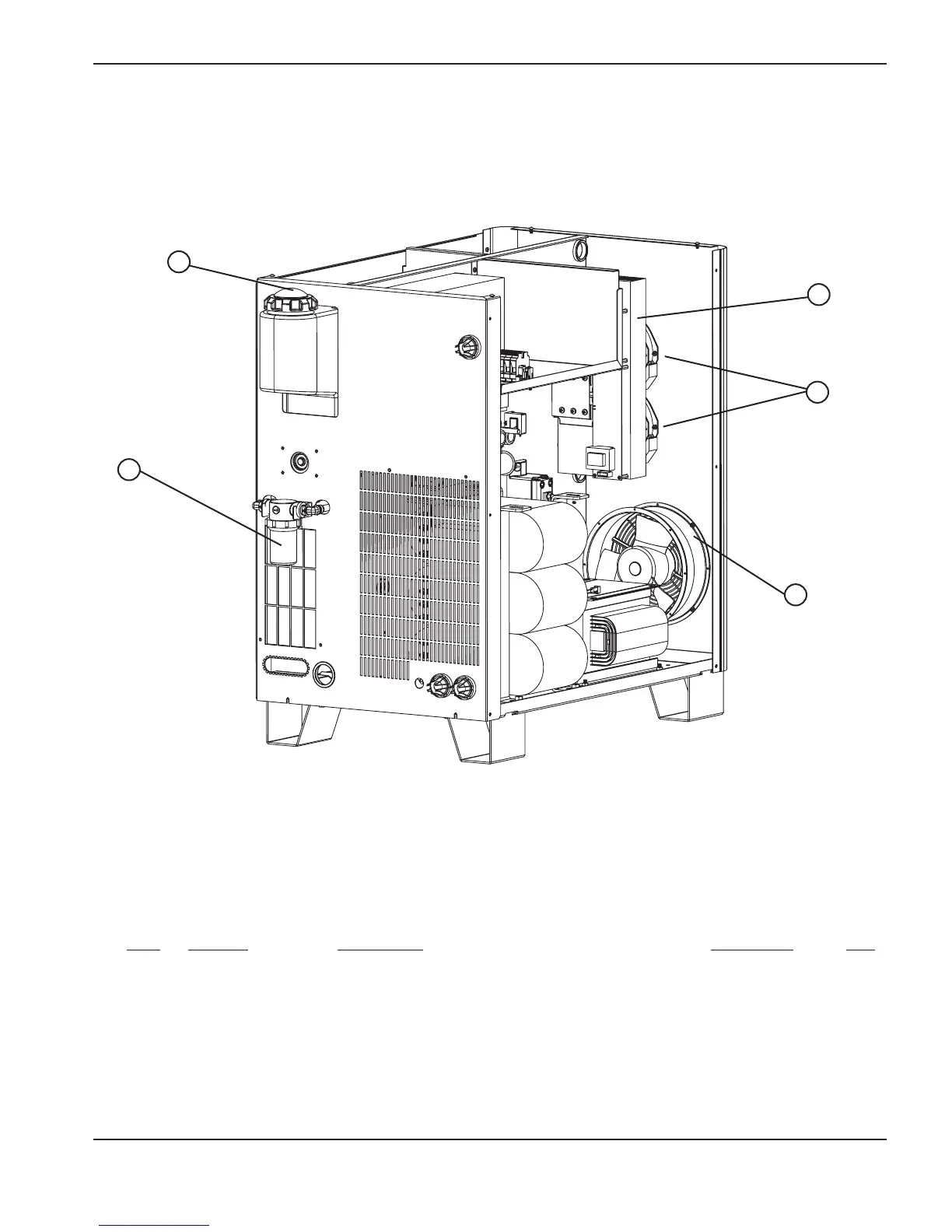

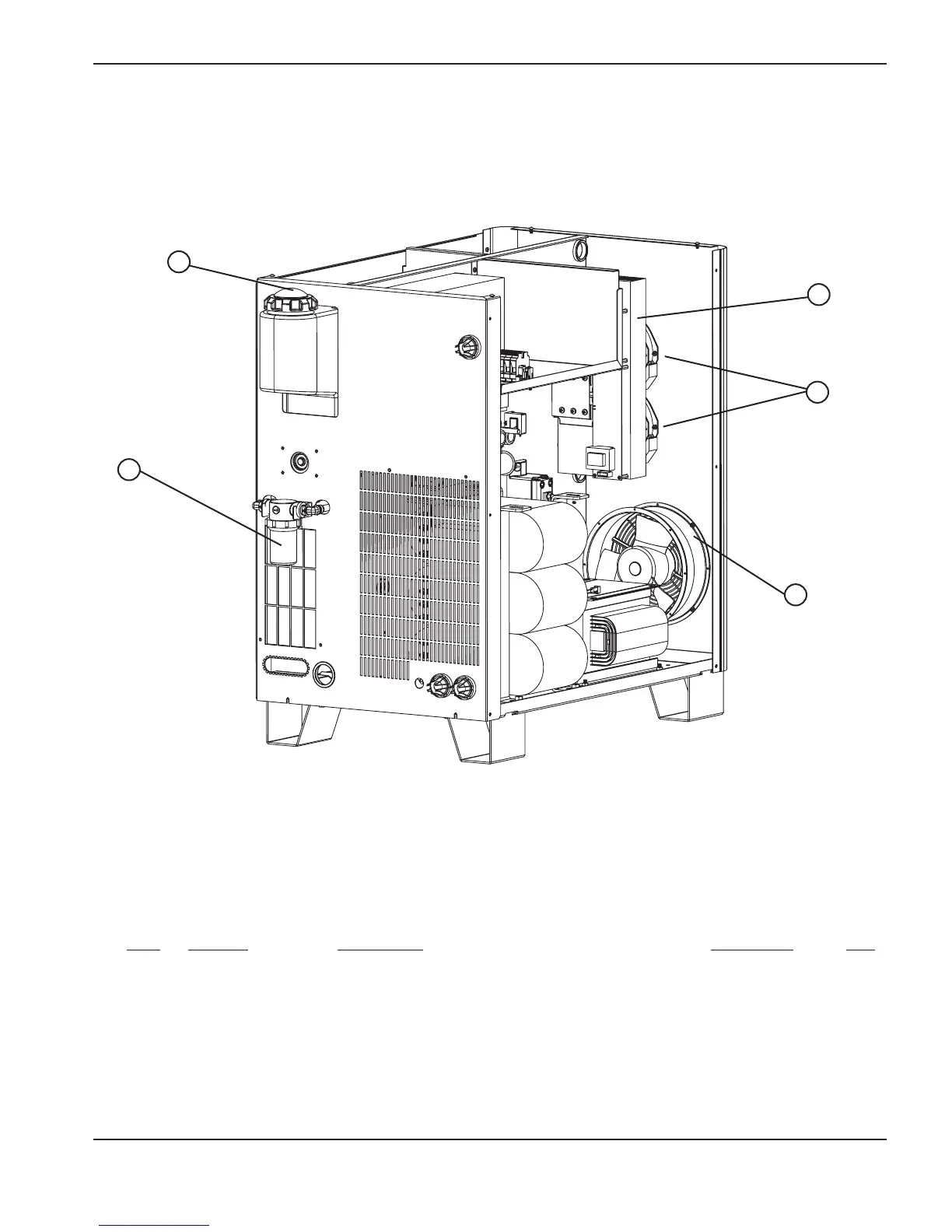

Power supply

Part

Item Number Description Designator Qty.

1 027634 Filter housing 1

027664 Filter element 1

2 127014 Cap: coolant resevoir 1

3 129792 Chopper assembly CH1 1

4 127039 6" fan :230 CFM, 115 VAC 50-60 HZ 2

5 027079 10" fan :450-550 CFM, 120 VAC 50-60 HZ 1

Loading...

Loading...