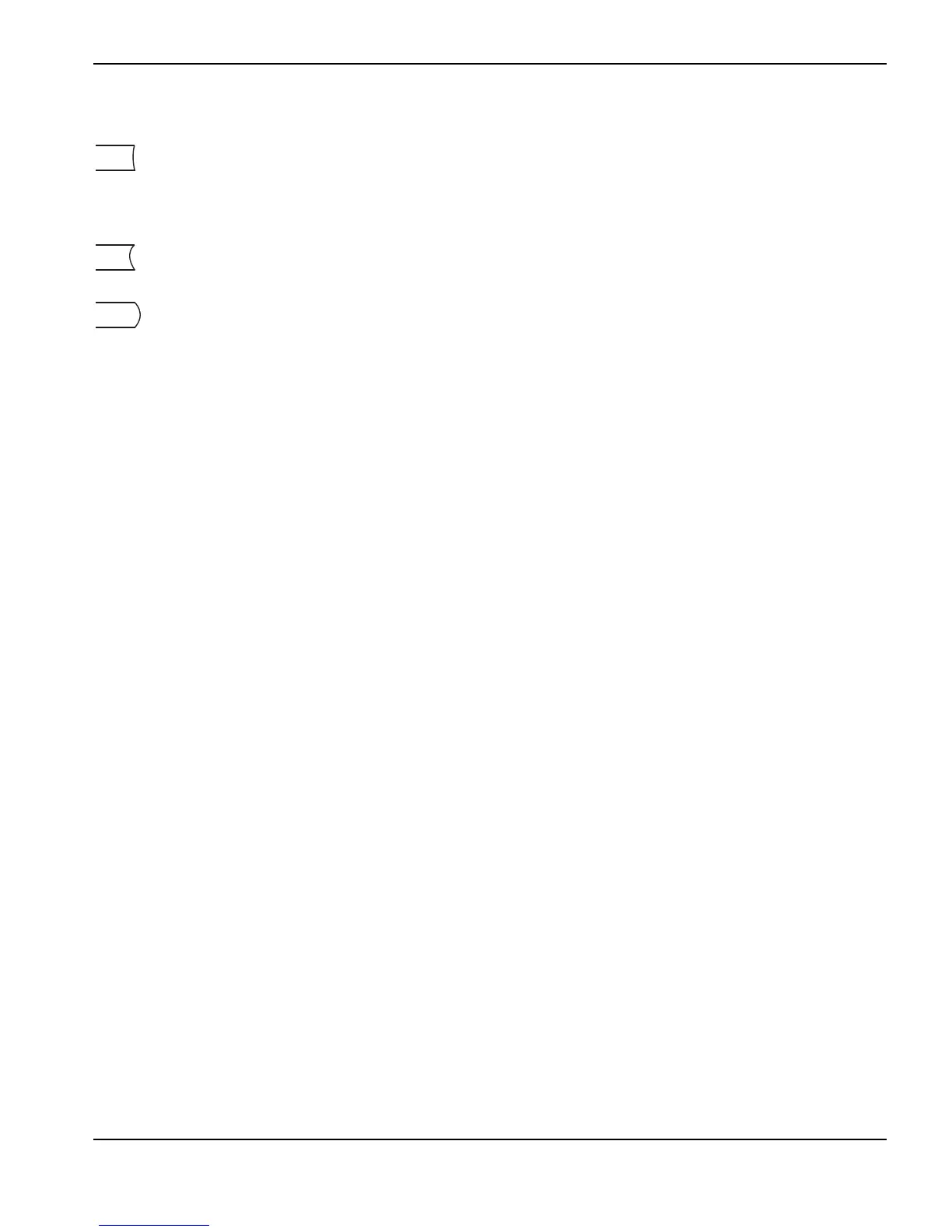

Straightness of the cut surface

A typical plasma cut surface is slightly concave.

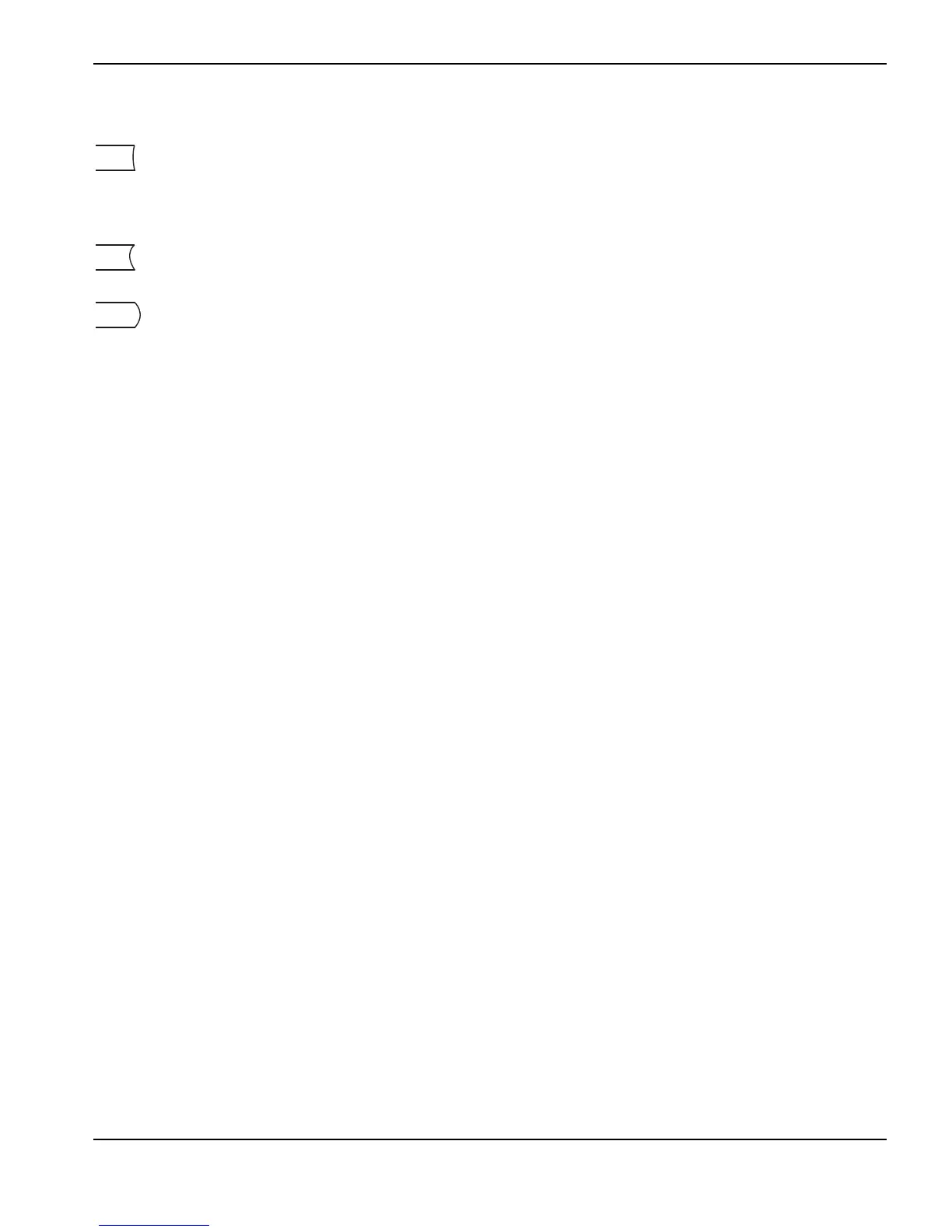

The cut surface may become more concave, or convex. Correct torch height is required to keep the cut

surface acceptably close to straight.

A strongly concave cut surface occurs when the torch-to-work distance is too low. Increase the arc voltage

to increase the torch-to-work distance and straighten the cut surface.

A convex cut surface occurs when the torch-to-work distance is too great or the cutting current is too high.

First, reduce the arc voltage, then reduce the cutting current. If there is overlap between different cutting

currents for that thickness, try the consumables designed for the lower current.

Additional improvements

Some of these improvements involve trade-offs, as described.

Piercing

The pierce delay should allow sufficient time to penetrate the full thickness of the material, but not so long that it allows

the arc to “wander” while trying to find the edge of a large pierce hole. As consumables wear, this delay time may need

to be increased. Pierce delay times given in the cut charts are based on average delay times throughout the life of the

consumables.

Using the “pierce complete” signal during piercing maintains the shield-gas pressure at the higher preflow pressure,

which provides additional protection for the consumables.

When piercing materials close to the maximum thickness for a specific process, there are several important factors to

consider:

• Allow a lead-in distance that is about the same as the thickness of the material being pierced. 50 mm (2 in)

material requires a 50 mm lead-in.

• To avoid damage to the shield from the build up of molten material created by the pierce, do not allow the torch

to descend to cut height until it has cleared the puddle of molten material.

• Different material chemistries can have an adverse effect on the pierce capability of the system. In particular,

high-strength steel and steel with a high manganese or silicon content can reduce the maximum pierce

capability. Hypertherm calculates mild steel pierce parameters with certified A-36 plate.

• If the system has difficulty piercing a specific material or thickness, increasing the shield preflow pressure can

help in some cases.

Trade-off: This may reduce starting reliability.

• Using a “flying pierce” (i.e. starting torch motion immediately after transfer and during the pierce process) can

extend the piercing capability of the system in some cases. Because this can be a complex process that can

damage the torch or other components, a stationary or edge start is recommended

How to increase cutting speed

• Decrease the torch-to-work distance.

Trade-off: This will increase the negative cut angle

Note: The torch must not touch the workpiece while piercing or cutting.

Loading...

Loading...