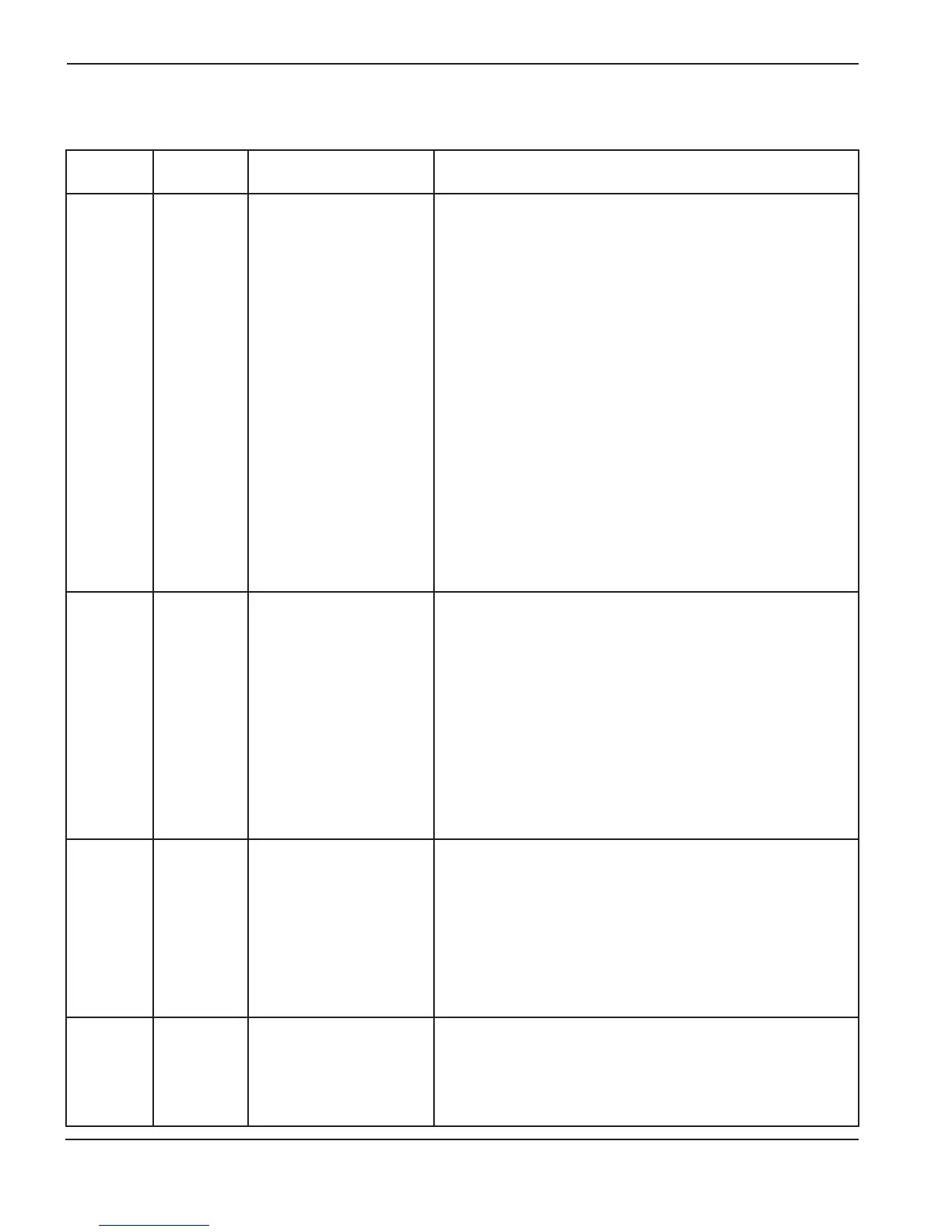

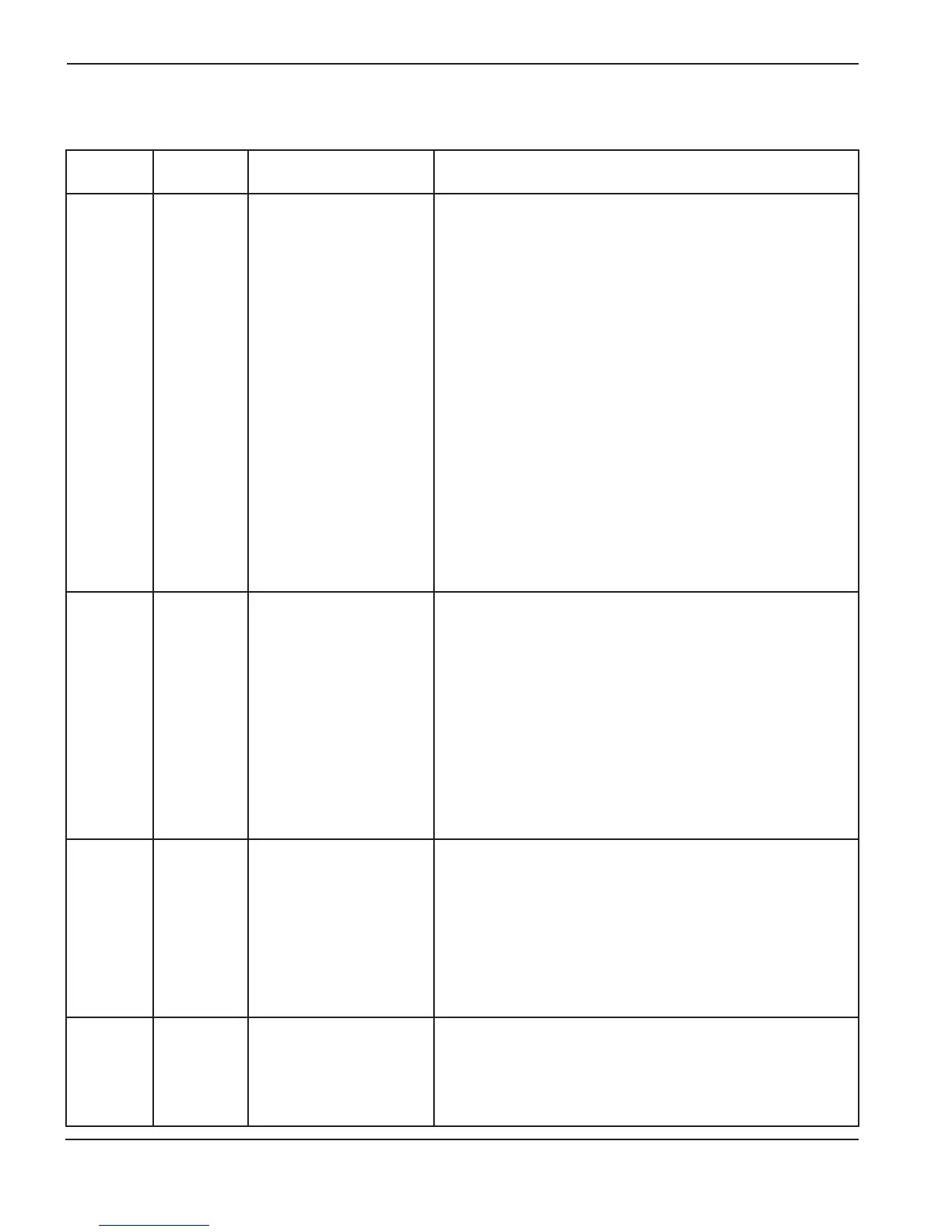

Error code troubleshooting – 5 of 16

Error code

number

Name Description Corrective action

047

High line

voltage

Line voltage is close to or

greater than the upper limit

of 138 VAC

(120 VAC +15%).

The normal upper limit for

operation is 132 VAC

(120 VAC +10%).

1. Verify input-line voltage at PCB2 in the power supply and

PCB1 in the cooler. Voltage needs to be within 10 % of

nominal (120 VAC).

2. Verify fuses on PCB2 in the power supply.

3. Verify 120 VAC voltage on plug J2.4, pins 3 and 4 on PCB2

in the power supply.

4. Verify the voltage on PCB1 in the cooler with a DC volt

meter. It Should be about 0.415 VDC between TP23 and

TP2 on PCB1.

5. If AC voltage on PCB2, J2.4, pins 3 and 4, is less than 132

VAC and DC voltage between TP23 and TP2 on PCB1 is

greater than 0.44 VDC, verify maximum 132 VAC voltage on

plug J4, pins 1 and 2 on PCB1. Verify wiring between PCB2

in the power supply and J4 on PCB1. If the voltage on plug

J4 is less than 132 VAC, but the DC voltage on TP23 and

TP2 is greater than 0.44, replace PCB1.

6. If the AC voltage on PCB2 in the power supply on plug J2.4,

pins 3 and 4, is less than 132 VAC and the DC voltage

between TP23 and TP2 on PCB1 in the cooler is also less

than 0.44 VDC, verify the CAN link between PCB3 in the

power supply and PCB1 in the cooler.

048 CAN error

An error occurred with the

CAN communications

between the power supply

and the gas console.

1. Verify that cable number 5 (power supply-to-gas console

control cable) is not damaged and is properly connected to

PCB3 and to the rear of the gas console.

2. Verify that cable number 6 (power supply-to-gas console

power cable) is not damaged and is properly connected

inside the power supply and to the rear of the gas console.

3. Verify that D1 (+5 VDC) and D2 (+3.3 VDC) are illuminated

on PCB2 inside the gas console. These LEDs indicate

power to PCB2.

4. If power is present at PCB2 and PCB3 and both gas

console cables are good, then PCB2 or PCB3 has failed.

Use the CAN tester to verify which board needs to be

replaced.

050

Start signal

is on at

power-up

Plasma start signal input is

active during power-up of

power supply.

1. Stop or clear the cutting program. The plasma start signal to

the plasma was not dropped after the last cut.

2. Verify that the CNC interface cable is not damaged.

3. Remove CNC interface cable from PCB3 and look for an

open circuit between pins 15 and 34.

4. If the circuit is closed either the CNC is issuing a plasma

start or the CNC interface cable is damaged.

5. If circuit is open, and LEDN300J is illuminated with CNC

Interface cable removed from PCB3, replace PCB3.

053

Low shield

gas pressure

Shield pressure is below

lower limit of 0.14 bar

(2 psi).

1. Verify gas supply pressure and that a sufficient volume of

gas remains in your supply.

2. Verify gas regulator settings on gas console with cut chart.

3. See Setting the supply regulators (Installation section).

4. Perform gas leak tests (Maintenance section).

5-14 HPR400XD Manual Gas Instruction Manual

MAINTENANCE

Loading...

Loading...