20

Explosion protection (pneumatic pump units)

Several solid metal springs ensure conductivity of the entire system.

Warning:

• Only use ATEX-certified pneumatic pump units, hydraulic hoses and tools in

areas with explosion hazard.

• Let authorized personnel inspect the explosion-proof system on a regular basis.

1. Make sure that all couplings and other connections are tight.

2. Connect a multimeter between the tool and one end of a grounding wire to measure the conductivity.

3. Connect one end of the grounding wire to the pneumatic pump unit.

4. Connect the other end of the grounding wire to an earthing point.

4.3

4.4

Air supply (pneumatic pump units)

1. Connect an air hose to the compressed-air inlet

2.

It is recommended to use a filter regulator

lubricator (FRL):

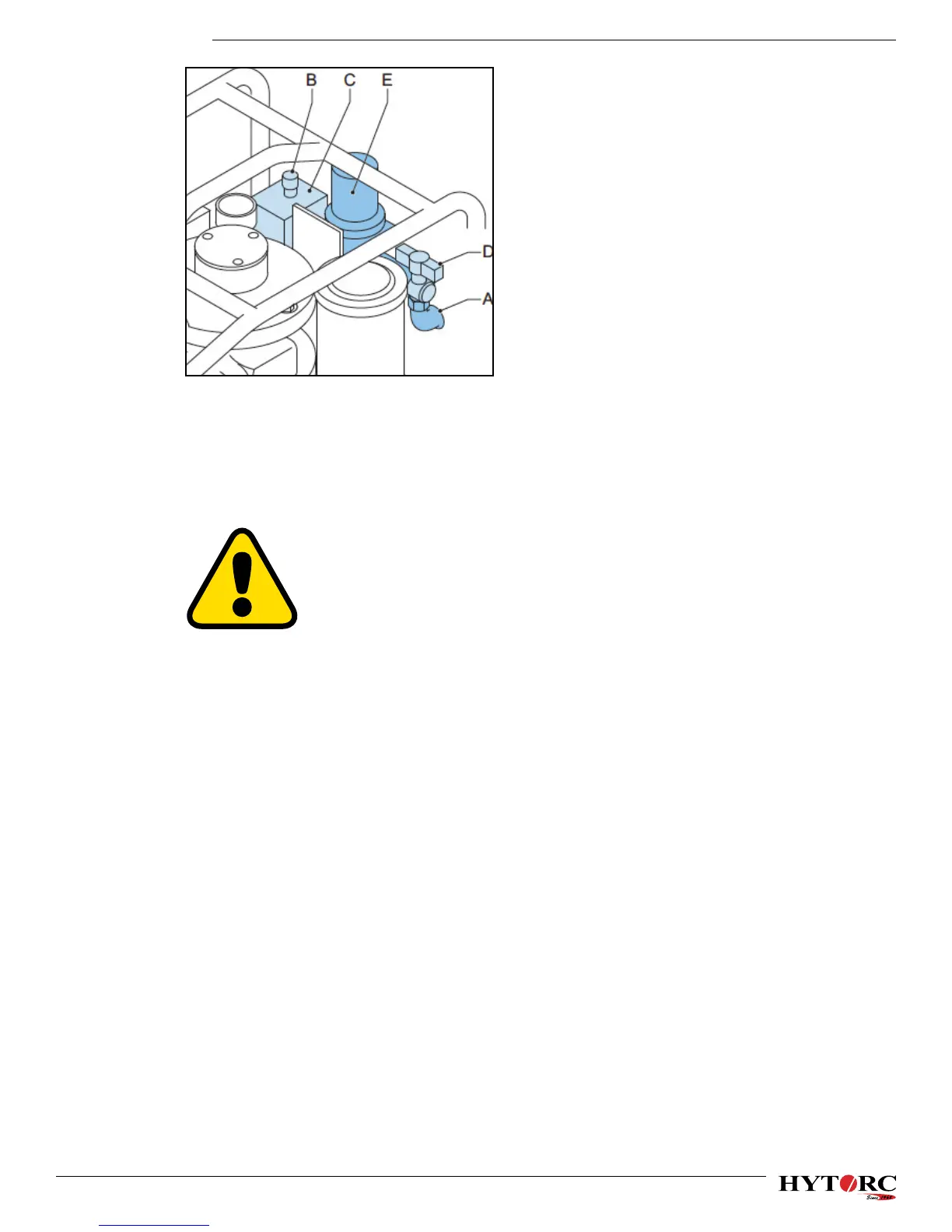

a) Remove the filter cap (B).

b) Fill the air lubricator (C) halfway with

hydraulic oil. Use only high grade hydraulic

oil (ISO VG 32 or ISO VG 46).

c) Install the filter cap (B).

d) Open the air shutoff valve (D).

e) Turn the air pressure regulator (E) to adjust the

air lubricator (C) to one drop per 60-90

seconds.

f) Close the air shutoff valve (D).

Installation (Cont’d.)

Loading...

Loading...