16

7.4 Installing the Load to the Slider

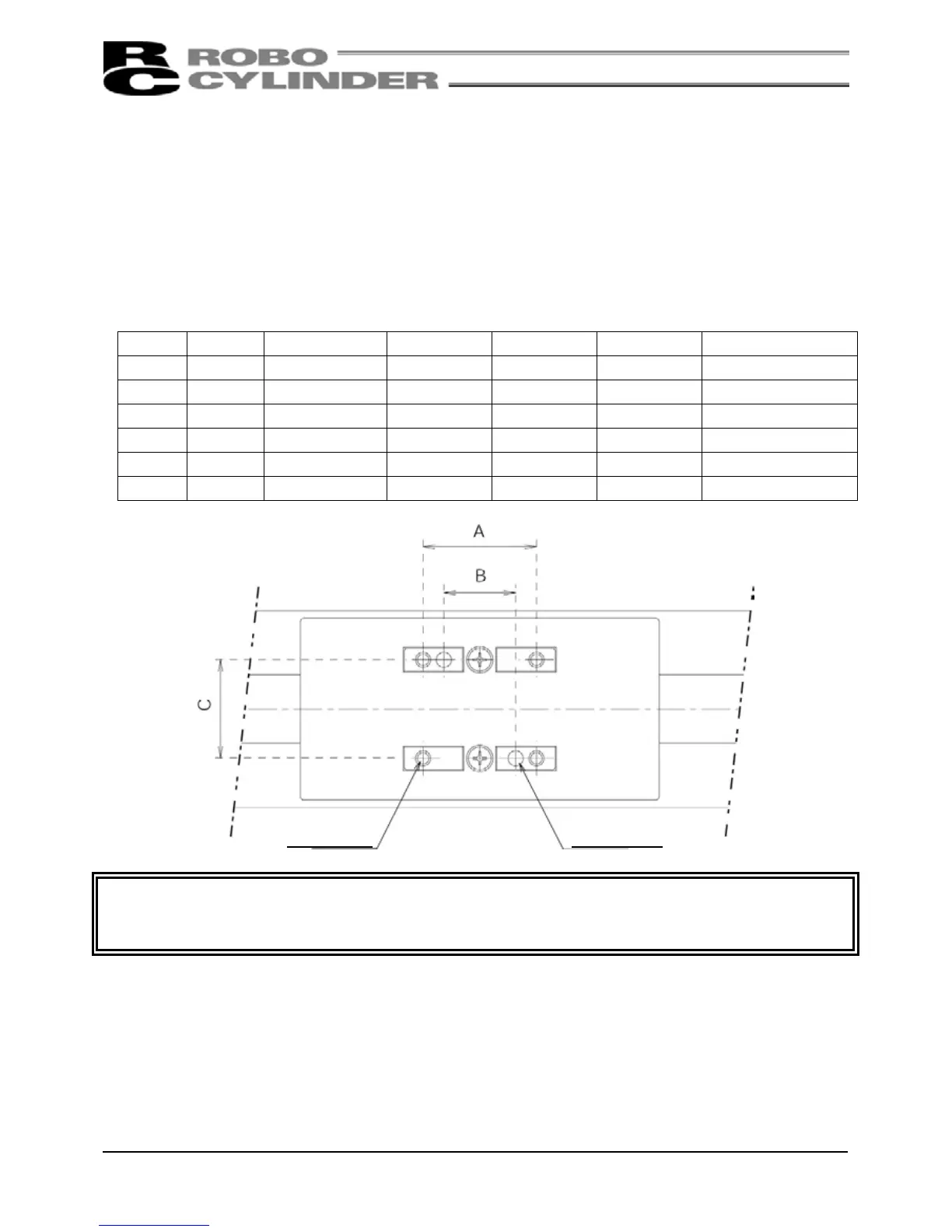

• Tapped holes are provided on the slider for installing the load. The method of clamping varies according to

how to mount the main body.

• In case of moving the main body with the slider secured, use the same tapped holes on the slider.

• Please use two reamed holes on the slider when repeatability of mounting and dismounting is required. When

fine adjustment of the squareness is necessary, use only one reamed hole to allow adjustment.

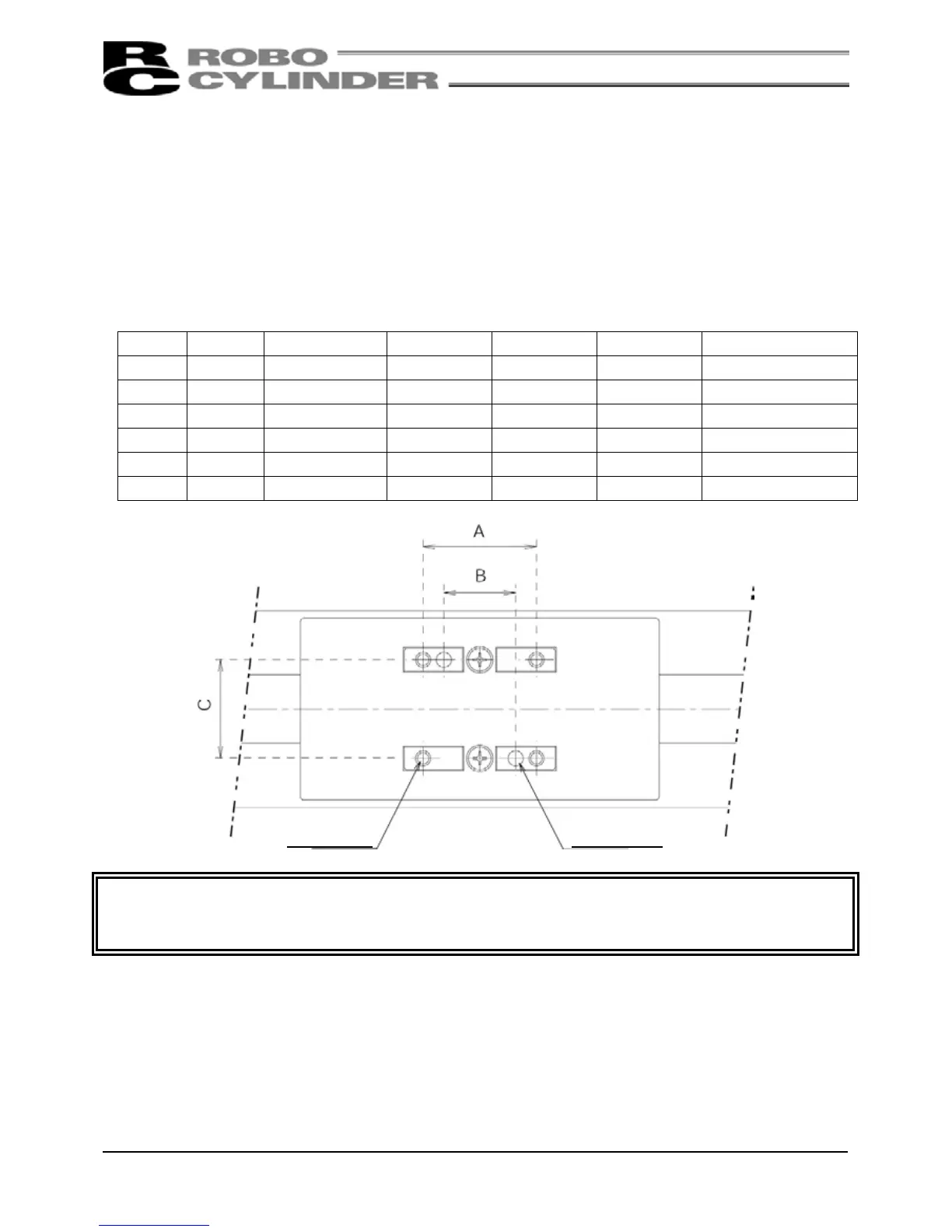

Sizes and depths of tapped holes and reamed holes on slider

Model Tap size Depth of thread A B C Reamed hole size

SA5C M4 9mm 30mm 19mm 26mm φ4H7, depth 6mm

SA6C M5 9mm 50mm 32mm 31mm φ5H7, depth 6mm

SA7C M5 10mm 50mm 32mm 39mm φ5H7, depth 10mm

SS7C M5 10mm 50mm 32mm 32mm φ5H7, depth 10mm

SS8C M8 10mm 75mm 45mm 45mm φ8H7, depth 10mm

HS8C M8 10mm 75mm 45mm 45mm φ8H7, depth 10mm

*Caution: When installing the load, do not allow adhesives, paints or other viscous substances to attach to the

stainless sheet. Also, avoid applying a concentrated force that will dent the sheet. It may cause the

slider to malfunction or damage the sheet.

Tapped hole

Reamed hole

Loading...

Loading...