20

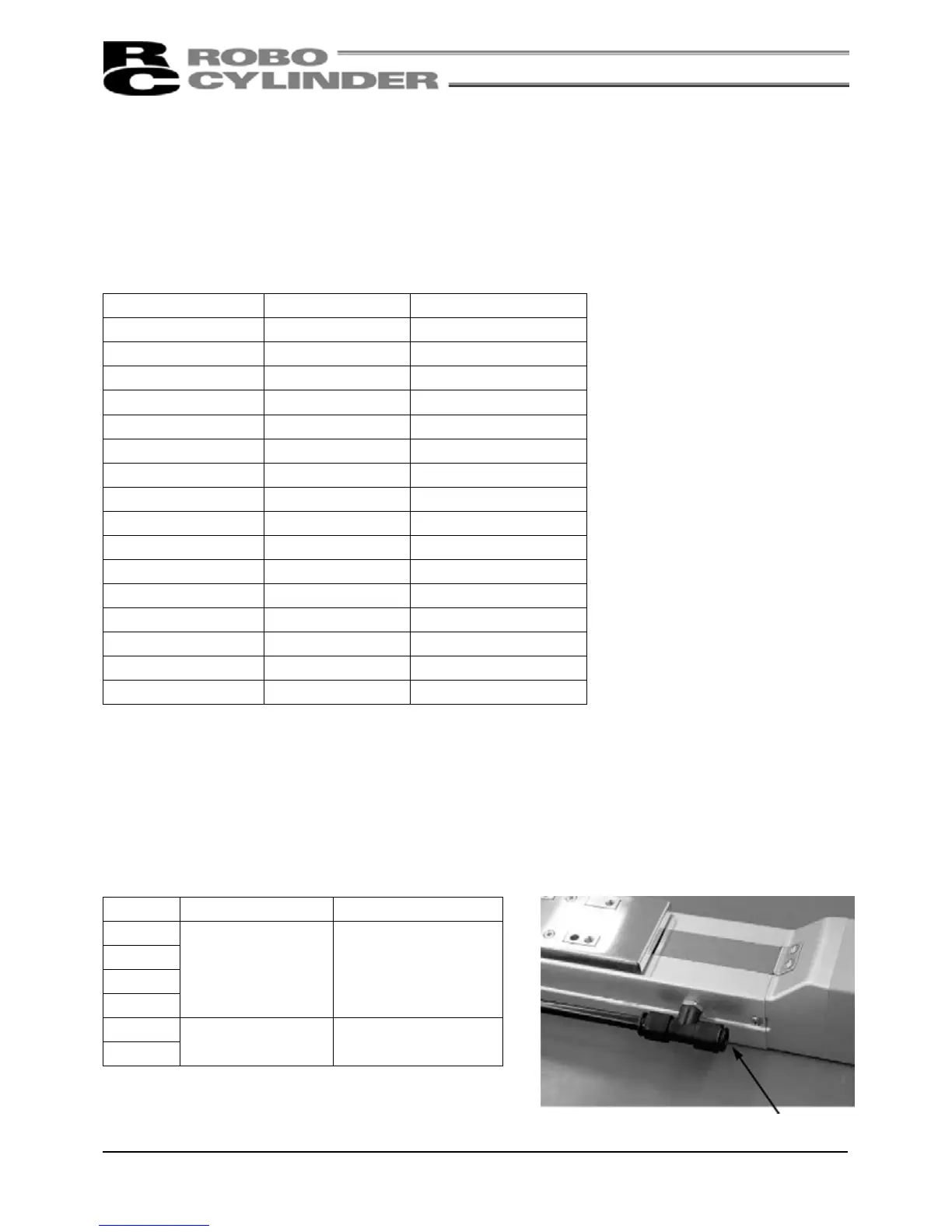

10. Cleanroom Specification

This actuator can deliver performance which ensures its operation in conformance with the requirements of

cleanliness class 10 (0.1μm) by suctioning air into the suction joint. The recommended suction rate of each

model at the maximum speed is specified below.

10.1 Recommended Suction Rate

Model Maximum speed Suction rate (NI/min)

SA5C, lead 12mm 600mm/s 50

SA5C, lead 6mm 300mm/s 30

SA5C, lead 3mm 150mm/s 15

SA6C, lead 12mm 600mm/s 50

SA6C, lead 6mm 300mm/s 30

SA6C, lead 3mm 150mm/s 15

SA7C, lead 16mm 533mm/s 70

SA7C, lead 8mm 266mm/s 40

SA7C, lead 4mm 133mm/s 30

SS7C, lead 12mm 600mm/s 50

SS7C, lead 6mm 300mm/s 30

SS7C, lead 3mm 150mm/s 15

SS8C, lead 20mm 666mm/s 80

SS8C, lead 10mm 333mm/s 40

SS8C, lead 5mm 165mm/s 20

HS8C 1200mm/s 180

• If there is suction equipment, check its capacity. If there is no suction equipment, select suction equipment

such as a vacuum pump and blower by referring to the values above.

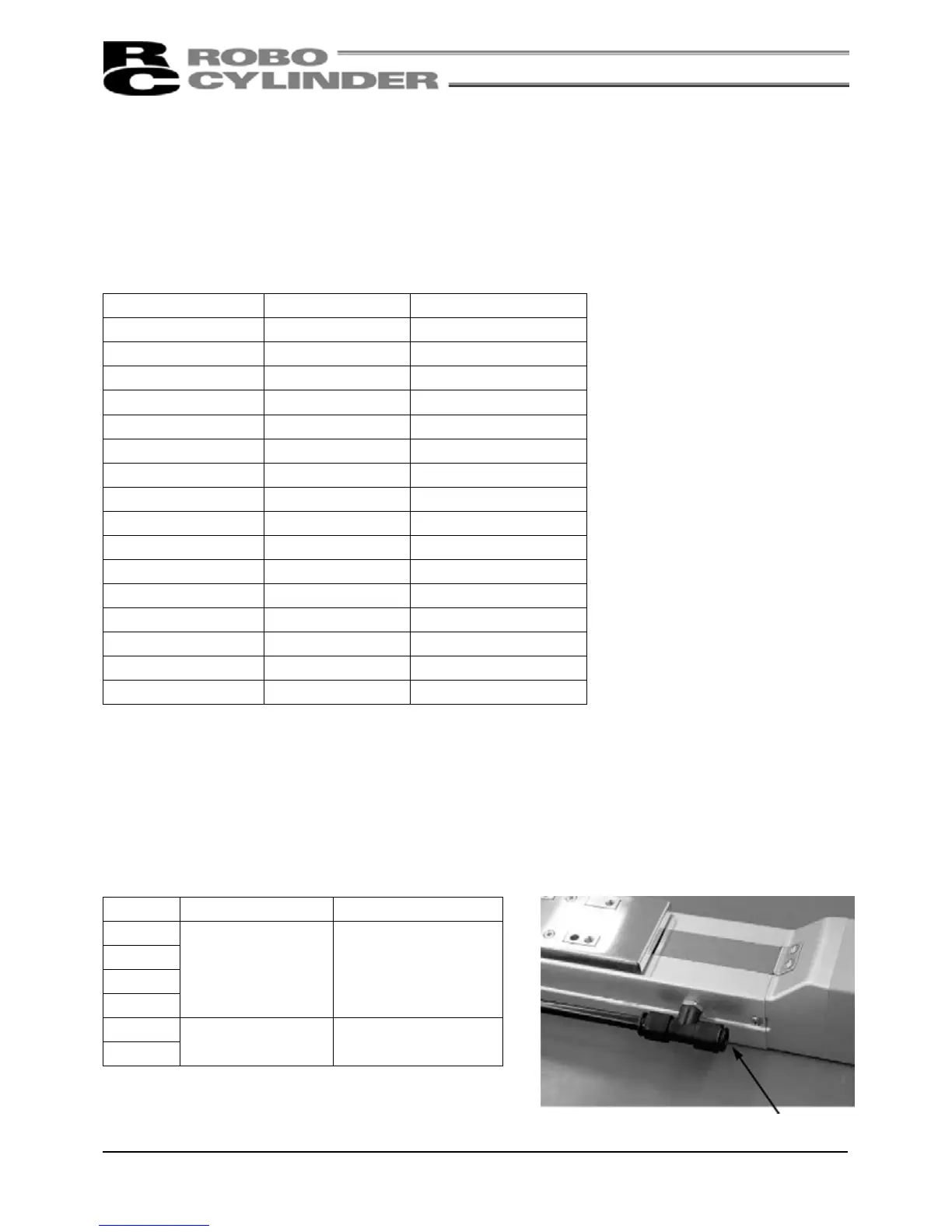

10.2 Suction Joint

• As for the suction joint, a one-touch type is employed and its structure allows the joint to be easily connected

with a commercial air tube.

Model Joint type Tube outer diameter

SA5C

SA6C

SA7C

SS7C

KAT08-U01 (SMC) φ8

SS8C

HS8C

KAT12-U03 (SMC) φ12

Loading...

Loading...