35

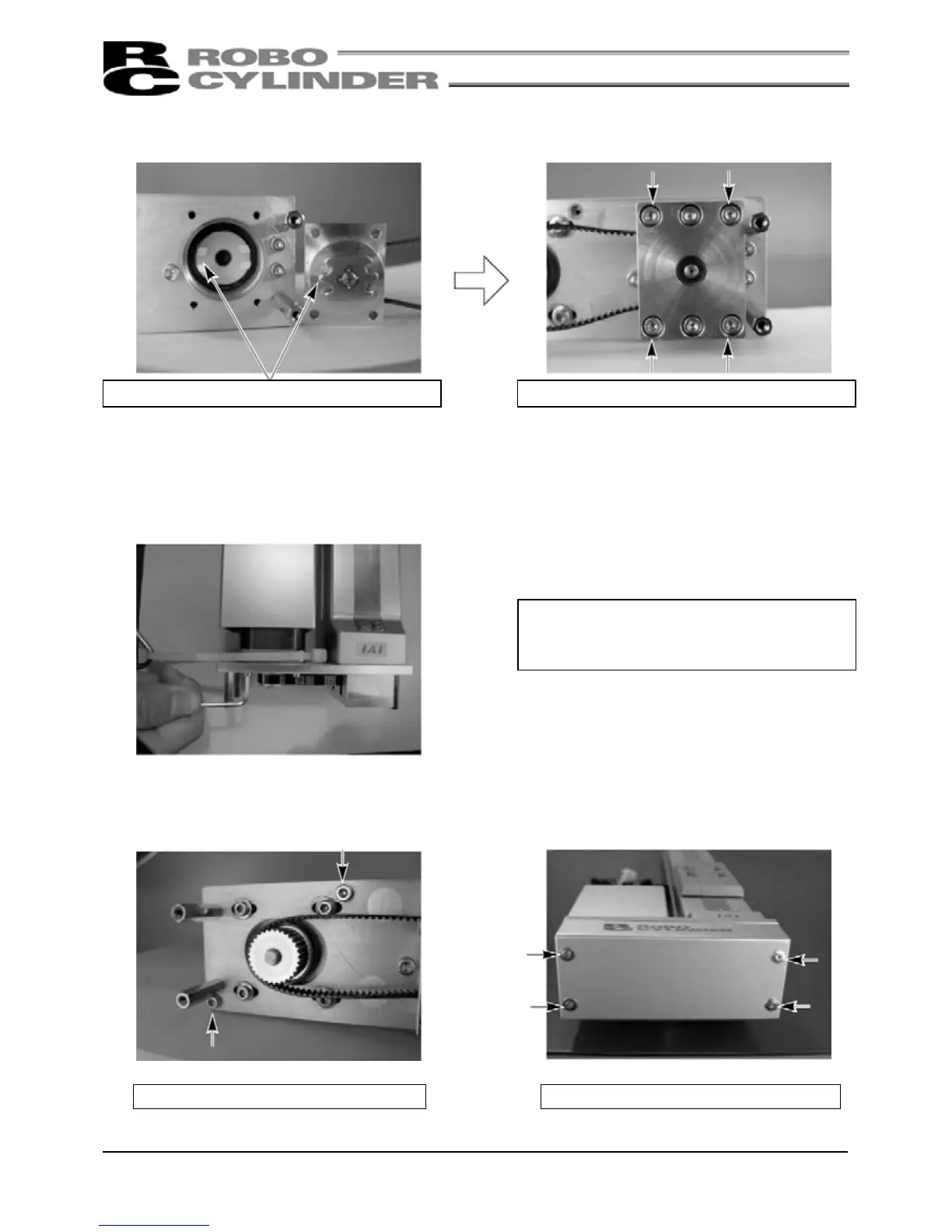

Tightening torque: 83N·cm (8.47kgf·cm) Tightening torque: 87.2N·cm (8.90kgf·cm)

9) Install the pulley assembly.

•

Align the angles of projections and depressions

on the couplings.

• Tighten the hexagon socket-head

screws (M3 × 22, 4 pcs.) using an Allen

wrench of 2.5mm across flats.

Align the angles of projections and depressions.

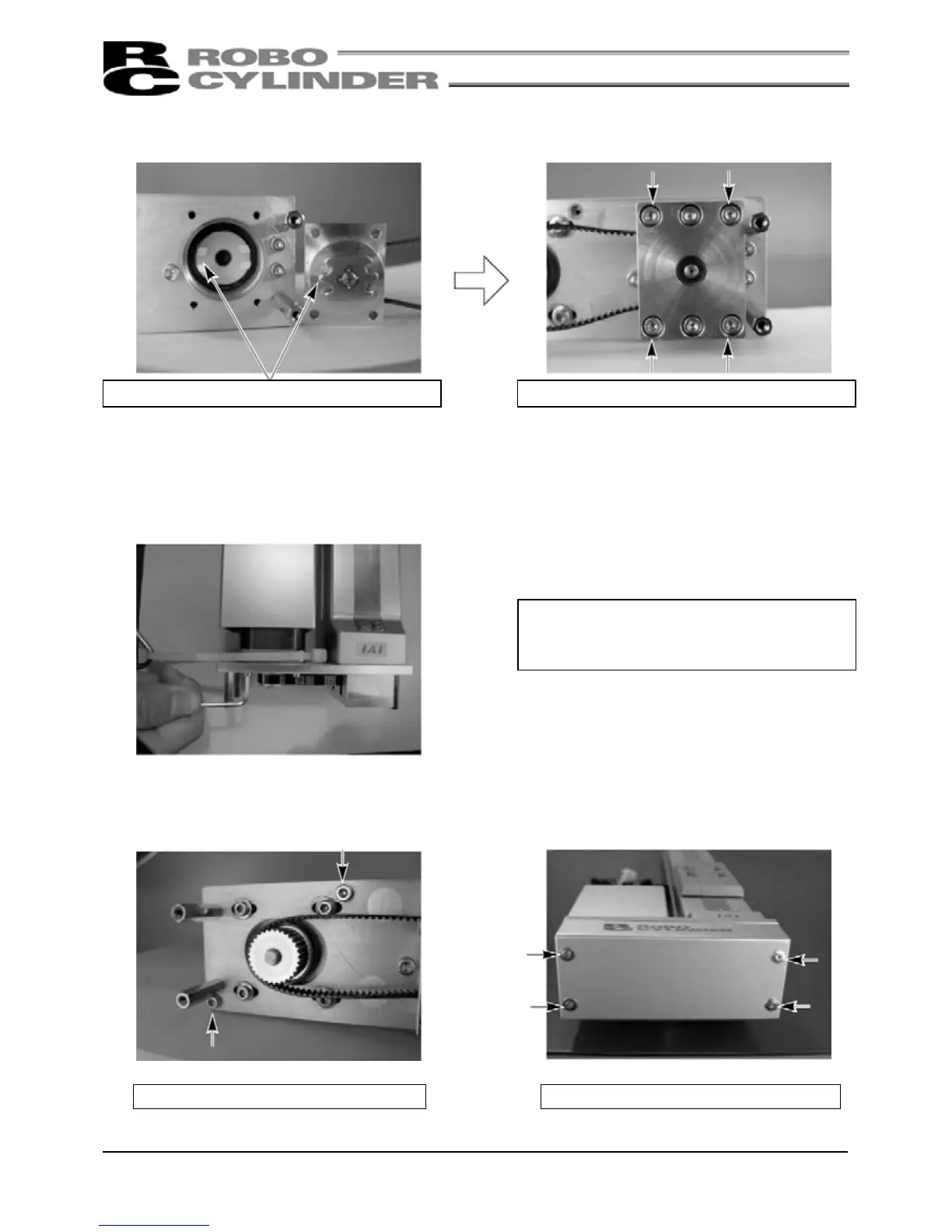

10) Loop the belt over the pulleys.

11) Pass a looped strong string (or long tie-band) around the motor-end flange and pull it with a tension

gauge to the specified tension. In this condition, uniformly tighten the adjusting bolts (hexagon

socket-head bolts: M3 × 10, 4 pcs.).

(Use an Allen wrench of 2.5mm across flats.)

Tightening torque: 83N·cm (8.47kgf·cm)

Tension: 2.5kgf

Adjusting bolt tightening torque:

162N·cm (16.5kgf·cm)

12) Install the motor cover.

Tighten the hexagon socket-head screws

(M3 × 12, 2 pcs.) using an Allen wrench o

2.5mm across flats.

13) Install the pulley cover.

Tighten the thin-head screws (M3 × 6, 4

pcs.) using an Allen wrench of 1.5mm

across flats.

Loading...

Loading...