99903514:TELESCOPIC CRANE: 3A-3

SECTION 3A: CYLINDER REPAIR

20120521

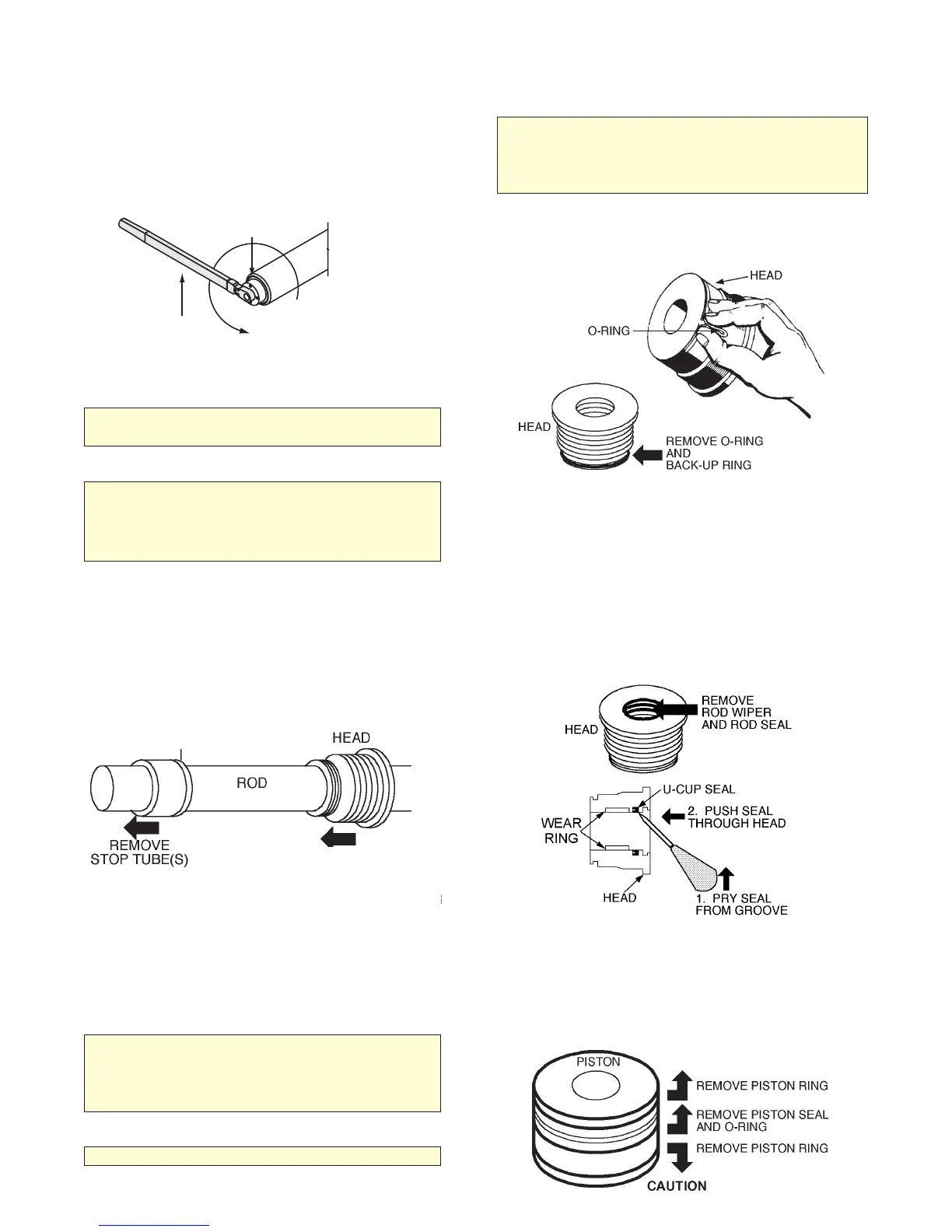

4. Secure the rod pin boss with a pin clamped in

the vise. Unscrew the piston using the spanner

wrench. Carefully inspect the piston and rod threads

for any damage or wear. Replace the part if

damaged threads are present.

CAUTION

DO NOT CLAMP THE ROD IN THE VISE. DAMAGE

TO THE ROD WILL RESULT.

CAUTION:

DO NOT USE A PIPE WRENCH TO TIGHTEN OR

LOOSEN THE HEADS. IT WILL DEFORM THE

METAL, DAMAGE THE MATING SURFACES, AND

PREVENT PROPER TORQUE MEASUREMENT.

5. Remove the stop tube(s) from the rod. Slide the

head down the rod until it makes solid contact

against the stop tube ring/wafer lock. Drive the stop

tube ring/wafer lock from the rod using a plastic

hammer against the top of the head. Use only

enough force to move the stop tube ring/wafer lock

while distributing the blows around the head rather

than in only one place.

6. Remove the head from the rod.

7. Inspect the cylinder interior and the rod for

dents, nicks, scratches, cracks, or other defects

which require repair or replacement.

WARNING

REPLACE CRACKED OR DENTED RODS OR

CYLINDER CASES!! FAILURE TO DO SO MAY

RESULT SERIOUS INJURY, DEATH, OR

EQUIPMENT DAMAGE.

CAUTION

ANY PROTRUSION WILL DAMAGE NEW SEALS.

NOTE

FURTHER WORK SHOULD BE PERFORMED IN A

WARM ENVIRONMENT OF 70°F OR MORE. THE

SEALS WILL BE MORE FLEXIBLE AND EASIER TO

MANIPULATE.

8. Work a slack section into the head seal static

o-ring and remove it from its groove. Lift the static

back-up ring from the groove using a plastic awl.

9. Position the head on the work surface with the

rod wiper at the top.

10. Slide the tip of the plastic awl under the rod wiper

and remove the rod wiper from the head.

11. Puncture the rod seal using a plastic awl. Pry it

out of the groove and push through the head. Remove

the rod wear ring(s) using the awl to pry it from the

groove and push it through the head.

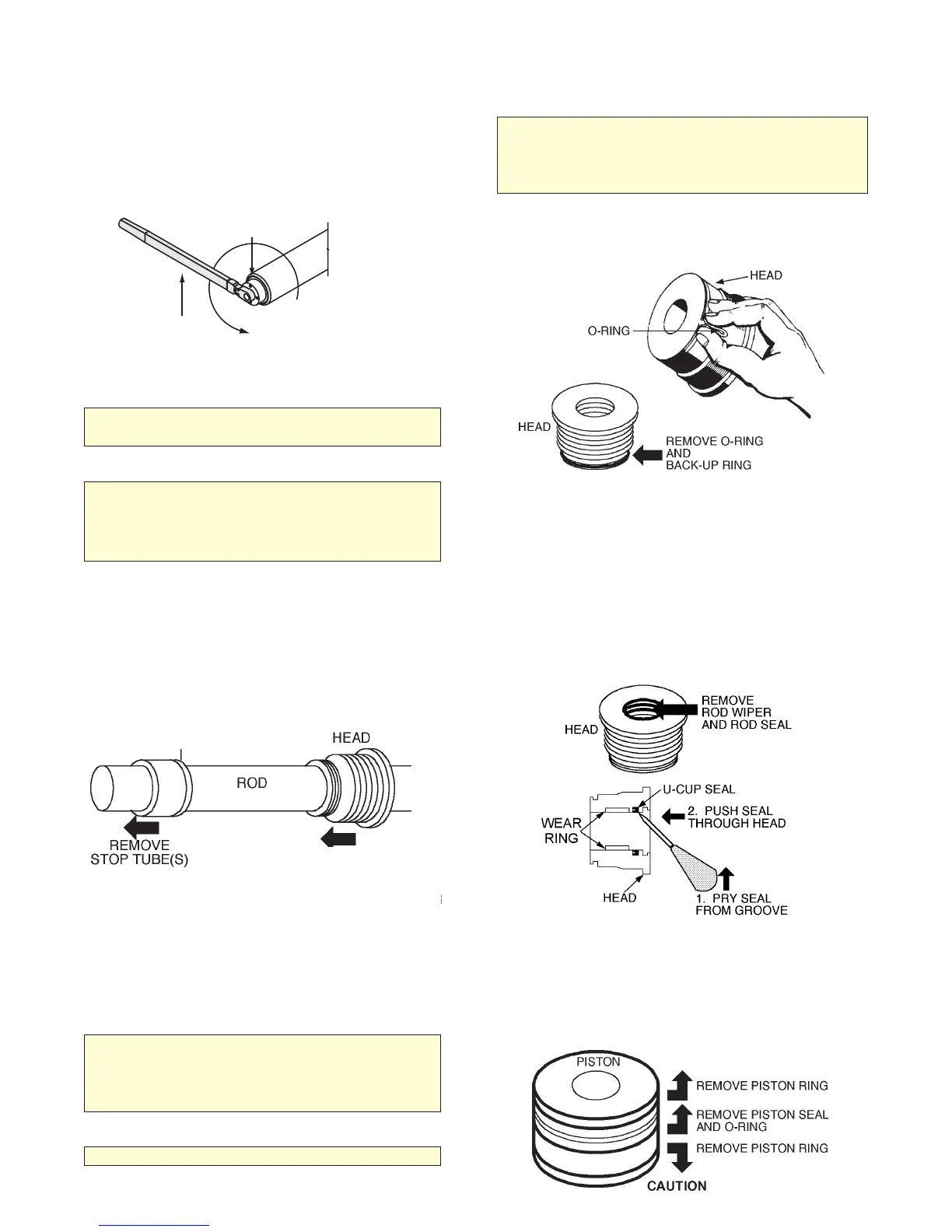

12. Spread the piston rings/ wear rings and slip them

over the lands and off the end of the piston nearest the

wear ring.

13. Carefully lift the dynamic piston seal out of its

groove using a thin blade. Take care not to nick the

edges of the groove. Twist and break the seal.

PISTON

PISTON SPANNER/

TORQUE WRENCH

ROTATE

THIS

DIRECTION

TO DISASSEMBLE

STOP TUBE

SLIDE HEAD

AGAINST STOP TUBE AND

DRIVE OFF USING

PLASTIC HAMMER

Loading...

Loading...