Maintenance 97

7 Maintenance

7.1 Maintenance schedule

Required tools

• 2 screw drivers, size 2

• 1 ring spanner wrench, 19 mm

• 8 mm hexagonal screw driver (delivered with Protec P3000).

Key for Maintenance Schedule:

• I Repair level I Customer

• II Repair level II Customer with technical training from INFICON

• III Repair level III INFICON service engineer

1) Depends on the environment

For all maintenance on the Protec P3000, the main power must be

disconnected first.

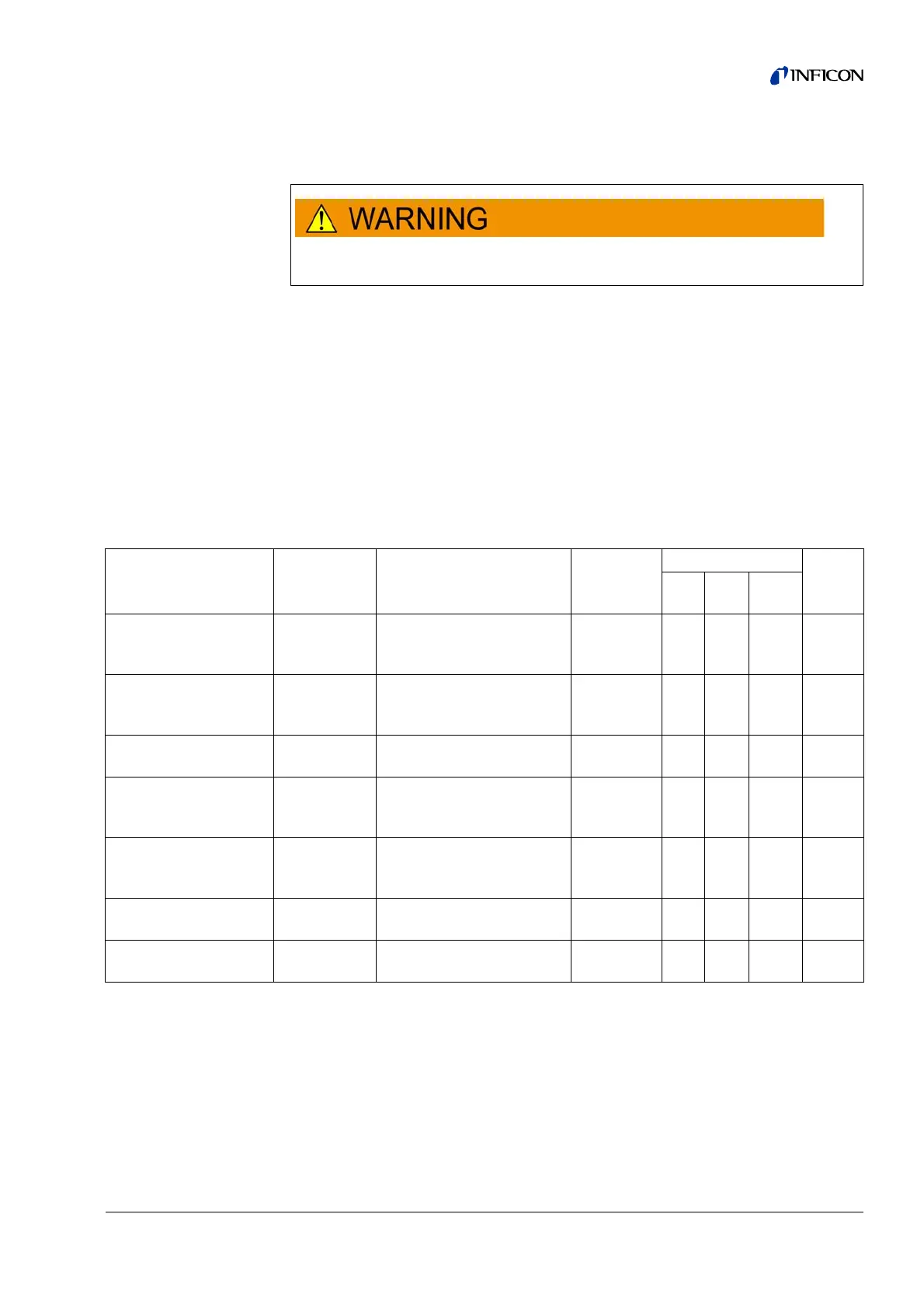

Required

maintenance

Sub

Assembly

Material

Description

Part no.

Operation hours

Repair

level

2000 5000

10.00

0

Check sinter filter and

replace if necessary

Sniffer tip

Sinter Filter for

Sniffertip SL3xx,

SL3000-x (5 pcs.)

200 03 500 X I

Replace if W35 „Flow

too low“

Sniffer tip

Felt for Capillary Filter

SL3xx,

SL3000-x (50pcs.)

200 001

116

1) I

Check internal filter and

replace if necessary

Main Unit internal Filter (10 pcs.)

200 001

680

XII

Maintenance of

diaphragm pump

Diaphragm

Pump

MVP015

Wearing parts kit for

Diaphragm pump

200 03 504 X III

Clean or replace the air

filter at the bottom of

the chassis

Main Unit

Air Filter Protec P3000

(104x154 mm; 5 pcs.)

200 001

552

XI

Replace gas reservoir

after 1 year

PRO-Check

Replacement gas reservoir

for PRO-Check

521-010 1) I

Replace filter pad Sniffer tip SL3000-XL

200 002

251

I

Loading...

Loading...