tinb29e1-c (2019-10) VGC083A_B.om 81

10 Service

Every INFICON module is calibrated prior to shipment using nitrogen. Care should

be exercised when using gases other than nitrogen (N

2

) / air (see previous sections

regarding the use of gases other than N

2

/air).

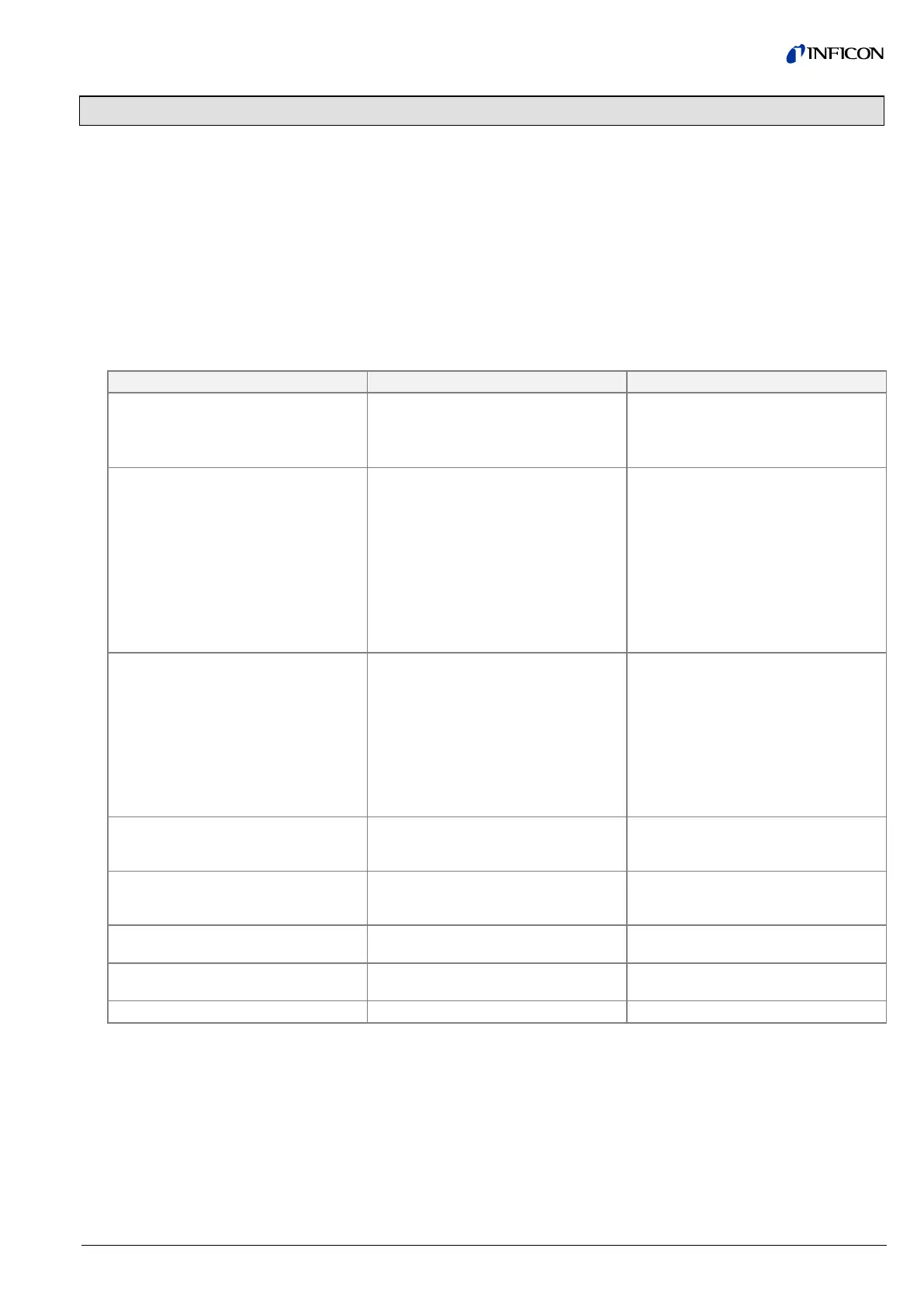

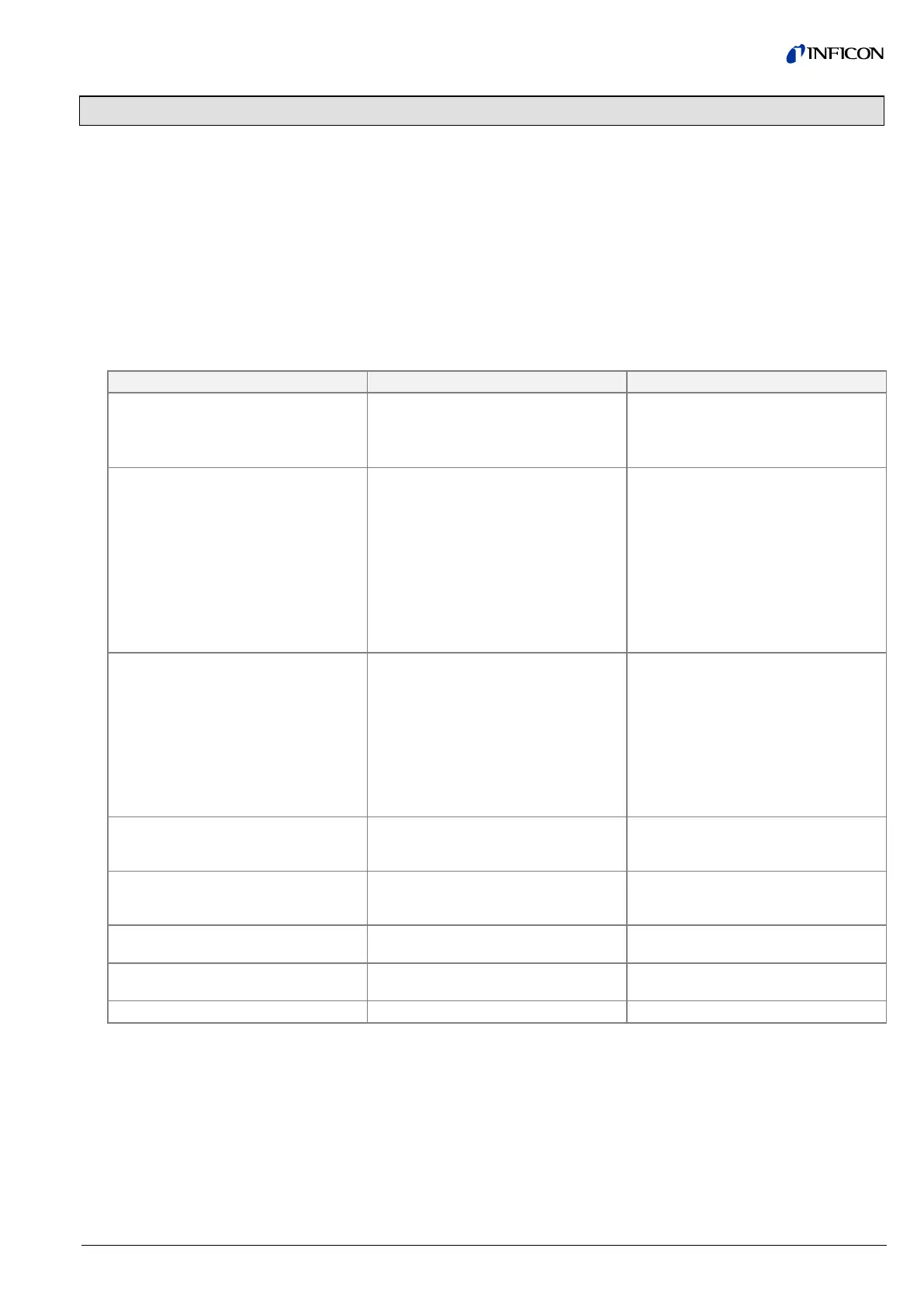

Display on VGC083 controller indicates

No power Check cable connections and verify that

The connector may not be wired

Check cable connections and verify that

Readings appear very different from

expected pressure

Sensor not in the proper location on

vacuum system

The process gas is different from the gas

(Nitrogen) used to calibrate the IG

Ensure the sensor is located in

appropriate location on vacuum chamber

Apply gas correction factor if applicable

Sensor has been dropped causing

Replace the ion gauge sensor tube

The gauge sensor tube is contaminated

Degas the sensor or replace the sensor

Leak in the vacuum system Re-check for leak in the system. Re-

check that all metal seals are used when

operating below 1.00 × 10

-7

Ion gauge cannot be turned on Pressure exceeds 1.00 × 10

-3

Torr at

0.10 mA (100 µA) emission current

Decrease pressure below required value

Pressure exceeds 5.00 × 10

-4

Torr at

4 mA emission current

Pressure exceeds 1.00 × 10

-4

Torr at

Decrease pressure below required value

Decrease pressure below required value

Emission Control not functioning Switch to the other filament, replace ion

gauge sensor tube due to possible fila-

ment failure or contamination

Research Screen shows filament voltage

is present but filament current stays at

Filament is open Switch to the other filament, replace

sensor or electronics

Research Screen shows filament voltage

and filament current are present but

Filament is contaminated or burned out Switch to the other filament or replace

sensor

Unable to initiate degas System pressure above 5.00 × 10

Torr Decrease pressure below the required

Voltage to filament too high Filament contaminated or near end of its

Switch to the other filament or replace

Setpoint does not actuate

10.2 Troubleshooting - IG

Loading...

Loading...