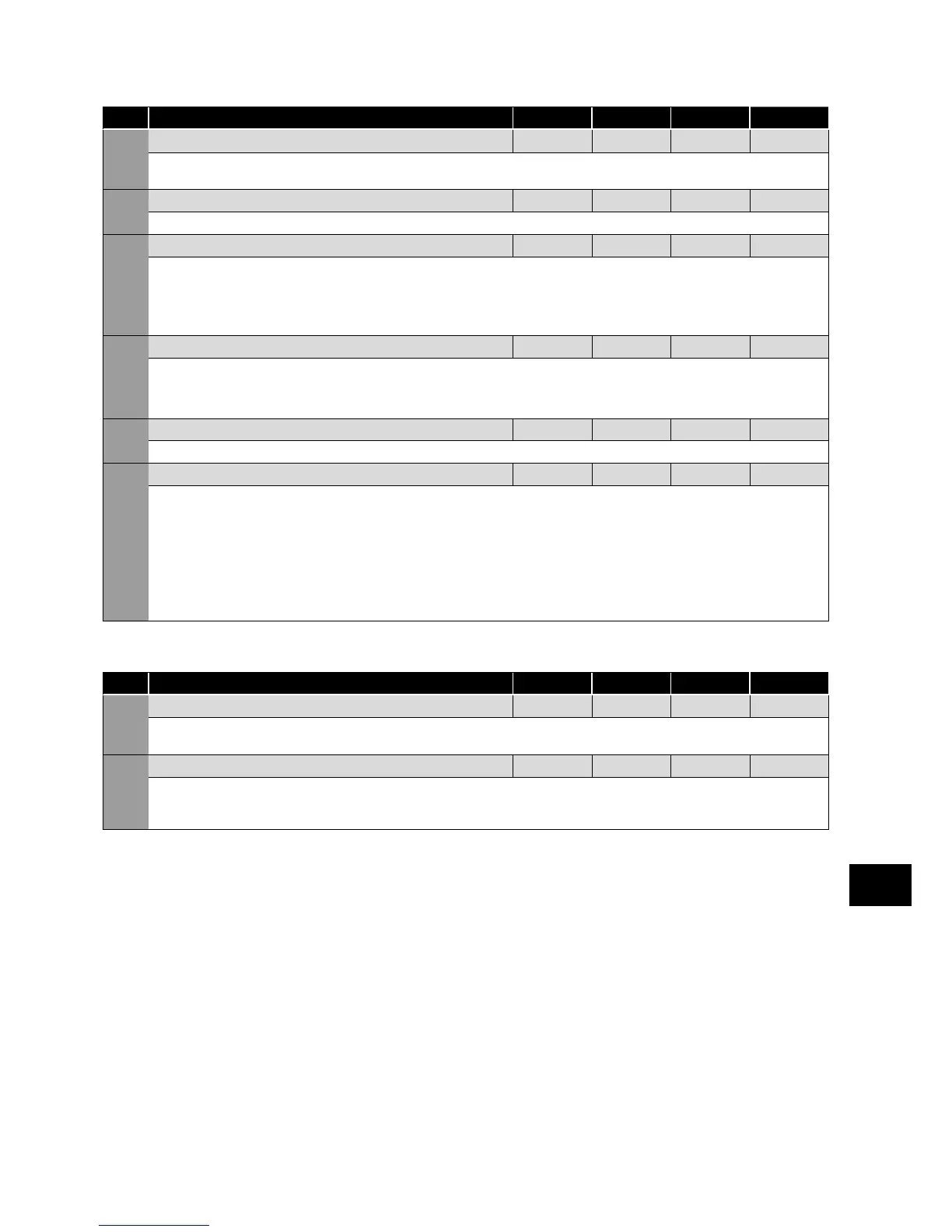

PI Control (relevant parameters)

Par. Description Minimum

Maximum

Default Units

P-41 PI Controller Proportional Gain 0.0 30.0 1.0 -

PI Controller Proportional Gain. Higher values provide a greater change in the drive output frequency in response to small changes in the

feedback signal. Too high a value can cause instability.

P-42 PI Controller Integral Time 0.0 30.0 1.0 s

PI Controller Integral Time. Larger values provide a more damped response for systems where the overall process responds slowly.

P-43 PI Controller Operating Mode 0 1 0 -

0: Direct Operation. Use this mode if when the feedback signal drops, the motor speed should increase.

1: Inverse Operation. Use this mode if when the feedback signal drops, the motor speed should decrease.

2: Direct Operation, Wake at Full Speed. As setting 0, but on restart from Standby, PI Output is set to 100%.

3: Reverse Operation, Wake at Full Speed. As setting 0, but on restart from Standby, PI Output is set to 100%.

P-44 PI Reference (Setpoint) Source Select 0 1 0 -

Selects the source for the PI Reference / Setpoint.

0: Digital Preset Setpoint. P-45 is used.

1: Analog Input 1 Setpoint. Analog input 1 signal level, readable in P00-01 is used for the setpoint.

P-45 PI Digital Setpoint 0.0 100.0 0.0 %

When P-44 = 0, this parameter sets the preset digital reference (setpoint) used for the PI Controller as a % of the feedback signal.

P-46 PI Feedback Source Select 0 5 0 -

Selects the source of the feedback signal to be used by the PI controller.

0: Analog Input 2 (Terminal 4) Signal level readable in P00-02.

1: Analog Input 1 (Terminal 6) Signal level readable in P00-01.

2: Motor Current Scaled as % of P-08.

3: DC Bus Voltage Scaled 0 – 1000 Volts = 0 – 100%.

4

: Analog 1 – Analog 2 The value of Analog Input 2 is subtracted from Analog 1 to give a differential signal. The minimum value is 0.

5: Largest (Analog 1, Analog 2) The larger of the two analog input values is always used for PI feedback.

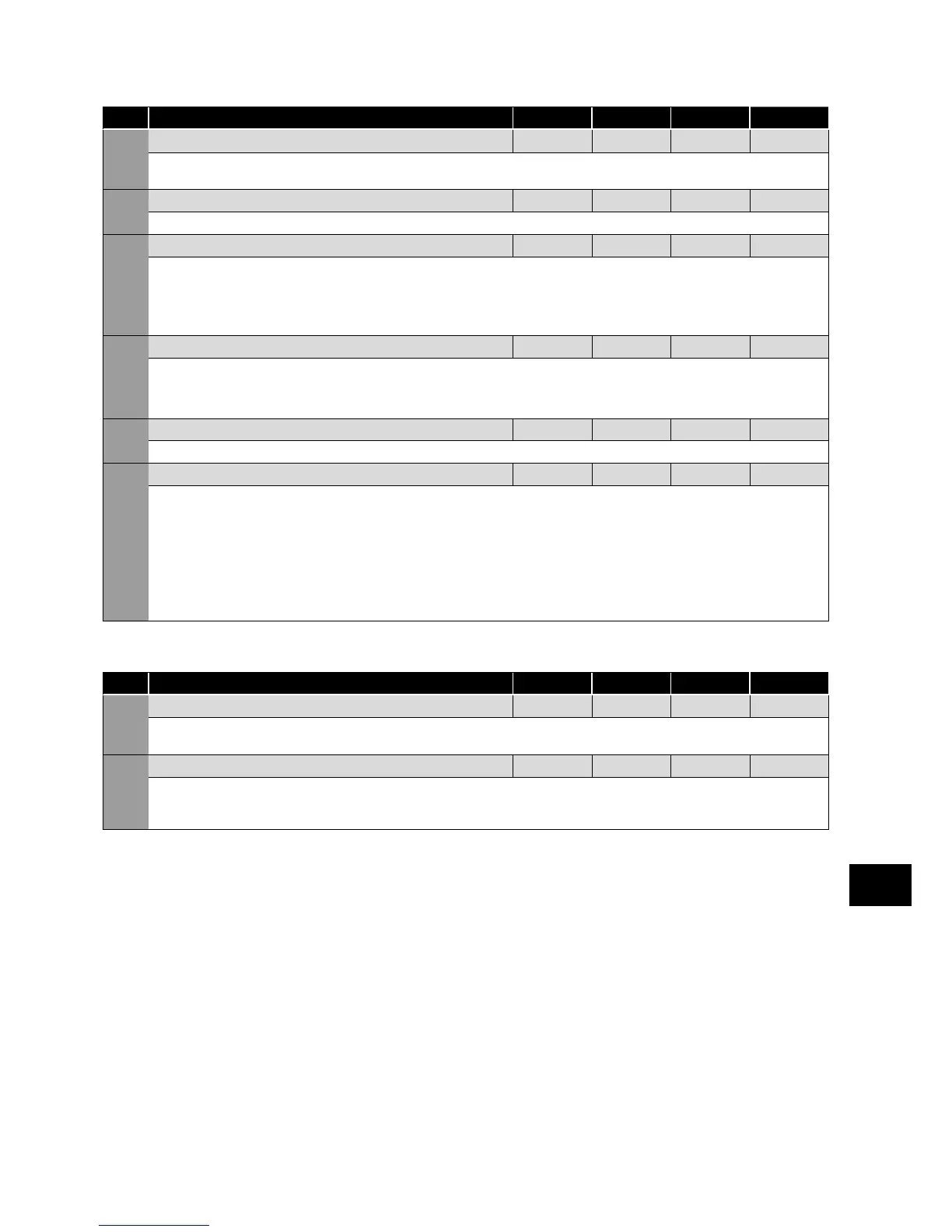

Standby Mode & Wake Up (relevant parameters)

Par. Description Minimum

Maximum

Default Units

P-48 Standby Mode Timer 0.0 25.0 0.0 s

When standby mode is enabled by setting P-48 > 0.0, the drive will enter standby following a period of operating at minimum speed (P-

02) for the time set in P-48. When in Standby Mode, the drive display shows , and the output to the motor is disabled.

P-49 PI Control Wake Up Error Level 0.0 100.0 5.0 %

When the drive is operating in PI Control Mode (P-12 = 5 or 6), and Standby Mode is enabled (P-48 > 0.0), P-49 can be used to define

the PI Error Level (E.g. difference between the setpoint and feedback) required before the drive restarts after entering Standby Mode. This

allows the drive to ignore small feedback errors and remain in Standby mode until the feedback drops sufficiently.

Parameters

6

Loading...

Loading...