GENERAL ENGINE MECHANICAL 6A – 55

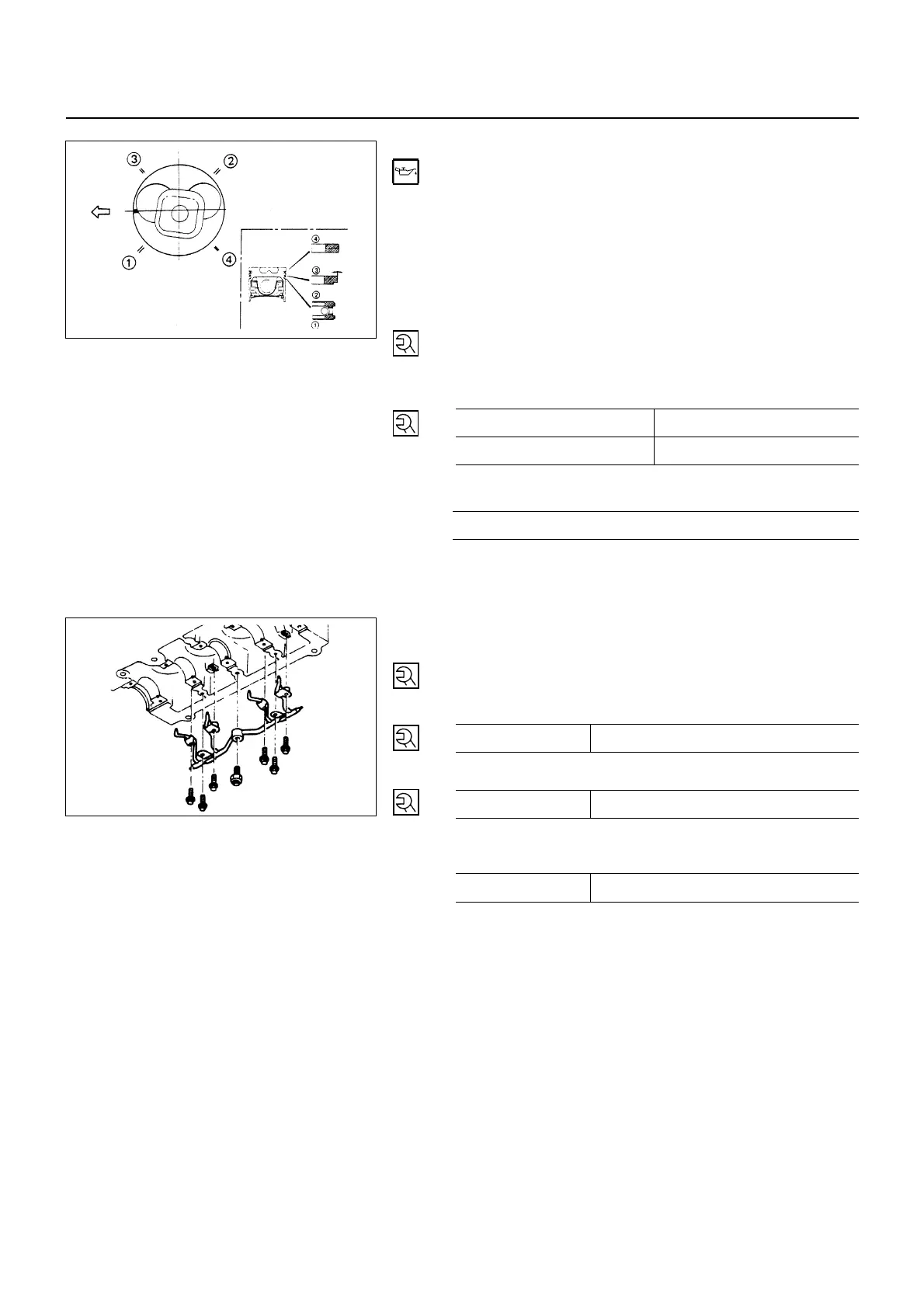

6. Piston and Connecting Rod

• Apply engine oil to the cylinder bores, the connecting

rod bearings and the crankshaft pins.

• Check to see that the piston ring end gaps are

correctly positioned.

• Insert the piston/connecting rod assemblies into each

cylinder with the piston ring compressor.

• The front marks must be facing the front of the engine.

5. Connecting Rod Bearing Cap

• Tighten the cap nuts in 2 steps, using angular

tightening method as shown in the following

specifications.

4JG2 N∙m (kg∙m/lb∙ft)

1st Steps 2nd Step

29 (3.0/22) 45° - 75°

4JA1, 4JB1, 4JB1TC N∙m (kg∙m/lb∙ft)

83 (8.5/61)

After tightening the cap nuts, check to see that the

crankshaft rotates smoothly.

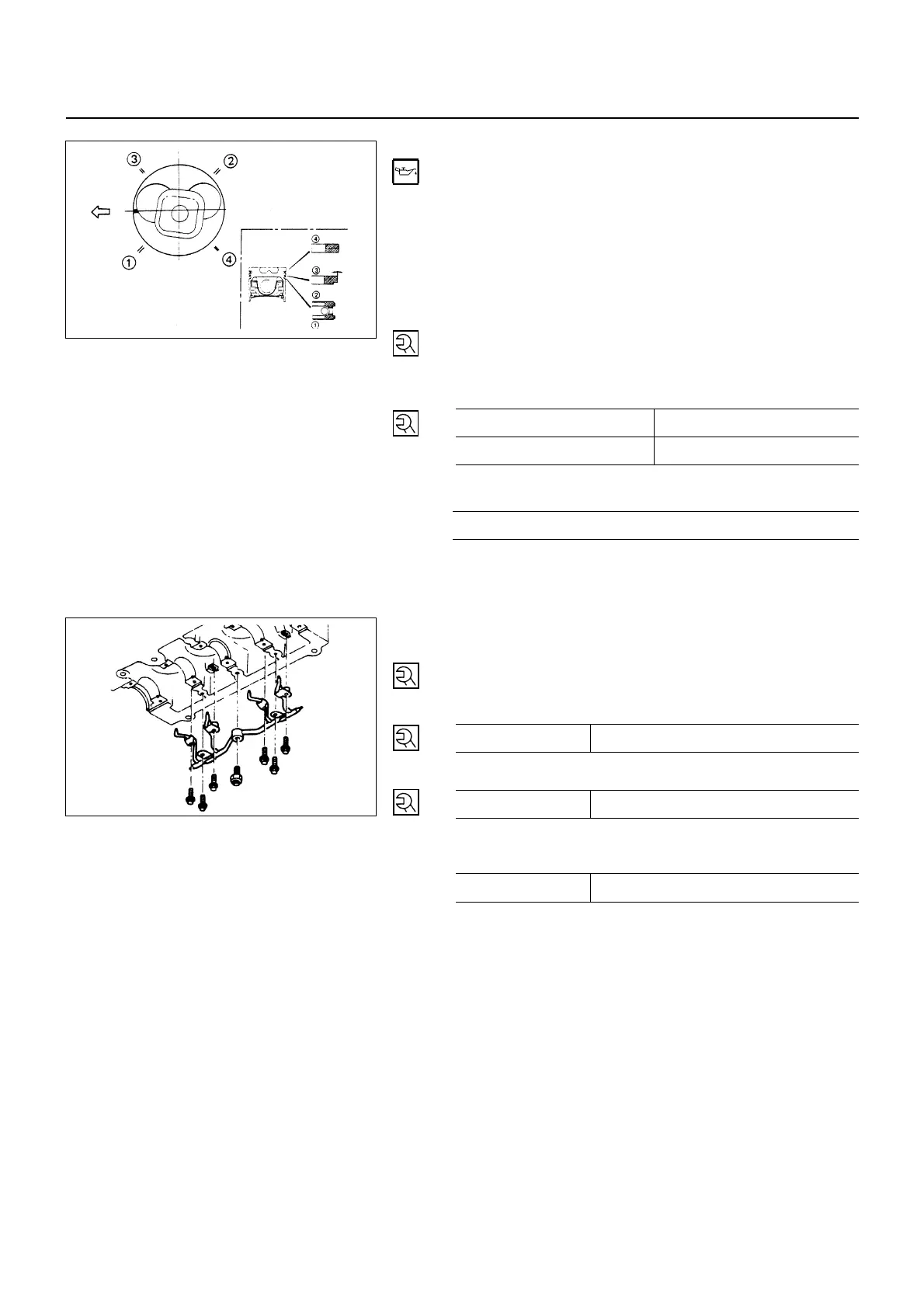

4. Piston Cooling Oil Pipe

• Install the piston cooling oil pipe to the cylinder body.

• Tighten the oil pipe bolts and relief valve to the

specified torque.

Oil Pipe Bolt Torque N∙m (kg∙m/lb∙ft)

(1) M8 x 1.25 19 (1.9/14)

N∙m (kg∙m/lb∙in)

(2) M6 x 1.00 8 (0.8/69)

Oil Pressure Regulating

Valve Torque N∙m (kg∙m/lb∙ft)

(3) M16 x 1.5 29 (3.0/22)

NOTE:

Check that there is no interference between the piston

and the oiling jet pipe by slowly rotating the

crankshaft.

3. Oil Pump Assembly

2. Oil Pan Assembly

Above works refer to “OIL PUMP” Section in this manual.

1. Cylinder Head Assembly

• Piston Head Projection Measurement Point

• Cylinder Head ASM

• Push Rod

• Rocker Arm Shaft ASM

Valve clearance adjustment.

Above works refer to “CYLINDER BLOCK” Section in this

manual.

6A-55-1.tif

6A-55-2.tif

Loading...

Loading...