ENGINE EXHAUST 6F – 5

INSTALLATION

4. Front exhaust pipe.

3. Front exhaust pipe fixing bolts and nuts.

• Tighten the fixing nuts to the specified torque

N∙m (kg∙m/lb∙ft)

50 (5.1/37)

2. Front exhaust pipe mounting bracket fixing bolt and nut.

• Tighten the fixing bolt to the specified torque

N∙m (kg∙m/lb∙ft)

40 (4.1/30)

1. Exhaust manifold fixing nuts

• Tighten the fixing nuts to the specified torque

N∙m (kg∙m/lb∙ft)

69 (7/51)

• Connect battery ground cable.

• After assembling each part, start the engine to check

for any leakage of gas at each connection.

Exhaust Brake Unit

INSPECTION

Operational inspection

• With the engine idling, operate the exhaust brake to

check for the sound of the valve hitting against the

stopper.

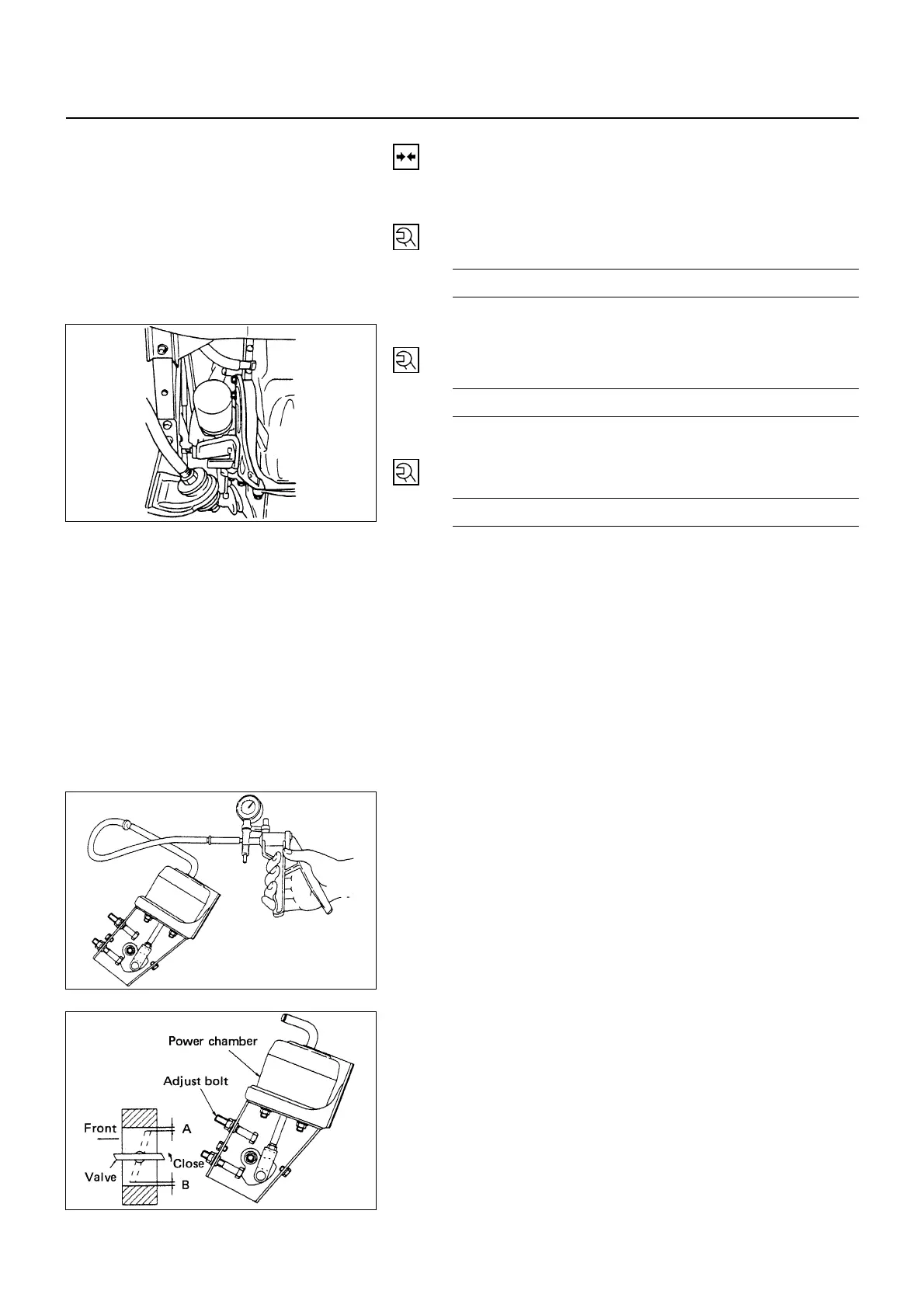

Unit inspection

• Check to see if the exhaust valve opens and closes

smoothly when the power chamber is

applied with a negative pressure (400 mmHg - 700

mmHg) by the vacuum pump.

• Check to see if the clearance between the valve and

the body is in the range of 0.1 mm - 0.2 mm (the

minimum of 0.1 mm) on an average of the points “A”

and “B” when the power chamber is applied with a

negative pressure (650 mmHg - 700 mmHg) by the

vacuum pump.

When the clearance is outside this range, adjust the

clearance with the adjust bolt.

6F-7-1.tif

6F-5-2.tif

6F-5-3.tif

Loading...

Loading...