CHARGING SYSTEM 6D3 – 19

7. Removal of Bearing (on the Rear Side) [Only for

Replace.]

Take out the bearing with a puller.

Insert it to see whether replacement is needed.

NOTE:

Conduct the bearing inspection mentioned below and

determine whether or not the bearing be replaced.

INSPECTION AND REPAIR

NOTE:

Standard values and limits vary with alternators, and

therefore, maintenance standards for each part

should be followed.

1) Fan

Check to see whether it is deformed.

2) Bearing

Turn it by hand to check for smooth and noiseless

turning.

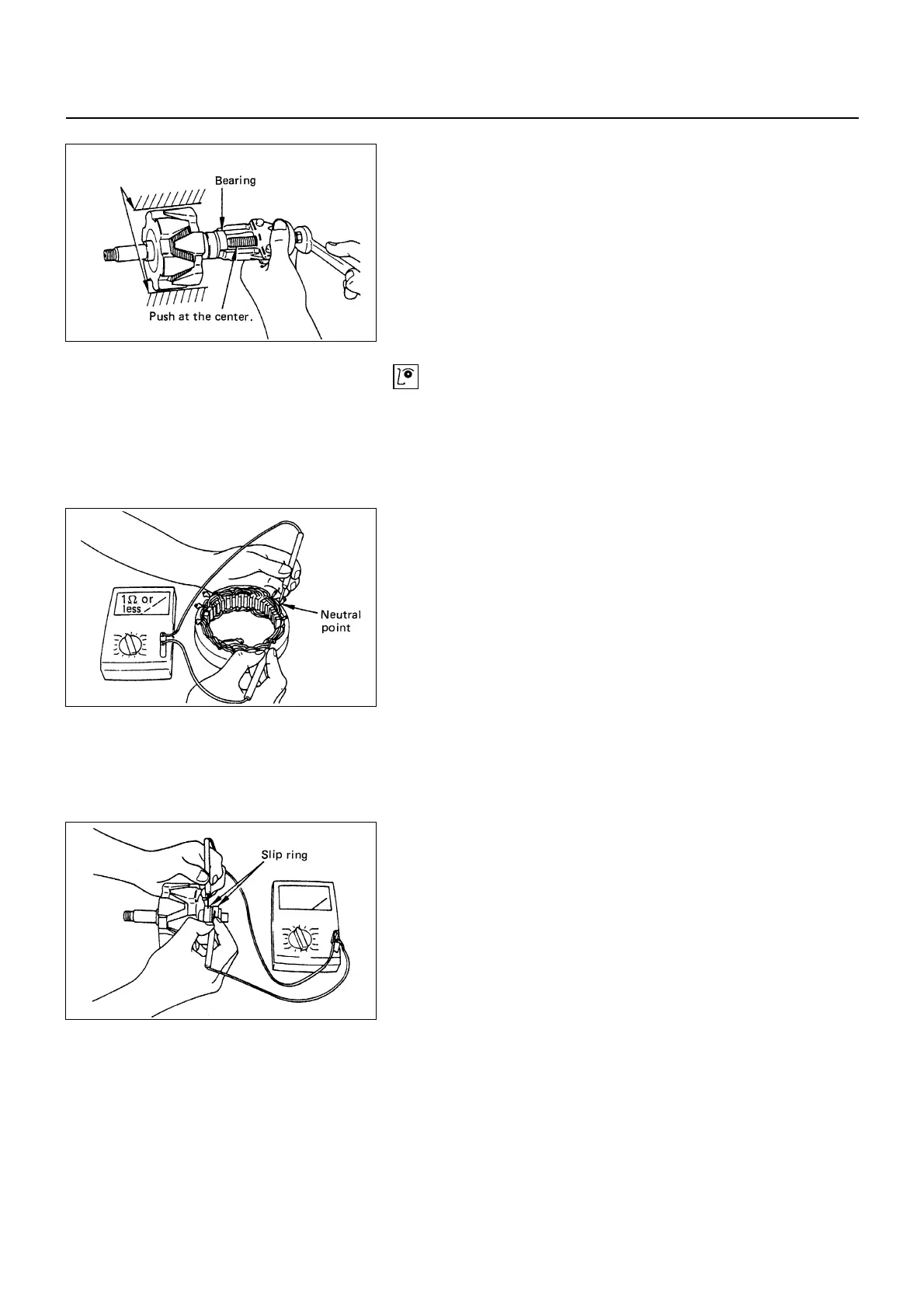

3) Stator

• Resistance between phases (neutral point and each

phase lead wire) should be 1Ω or less.

• Insulation resistance between the core and stator coil

should be 0.1MΩ or more by a 500V megohmmeter.

NOTE:

If there is no continuity, the connection of lead wire

should be checked as the disconnected stator coil

cannot be considered.

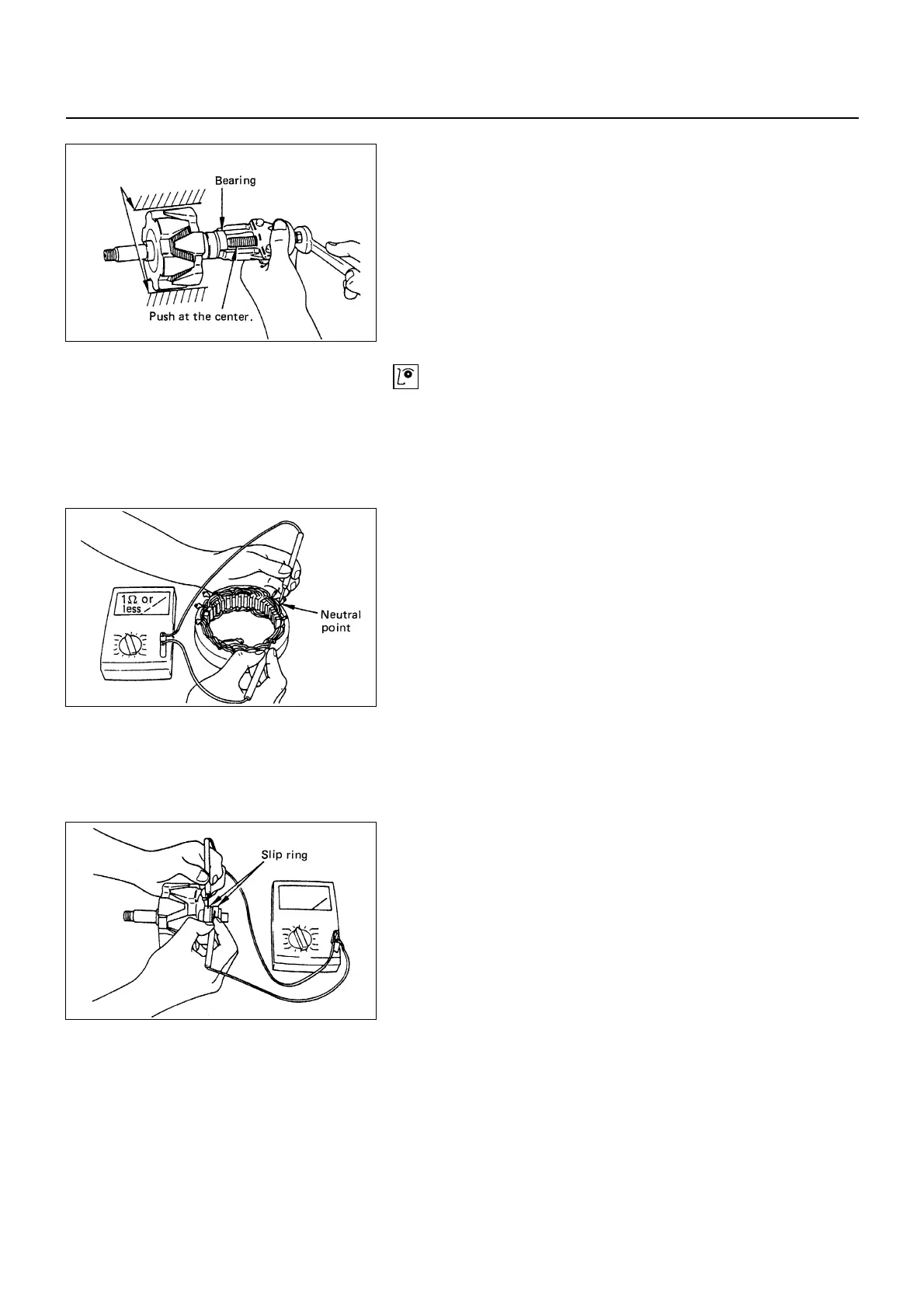

4) Rotor

• Resistance between slip rings as shows in the

illustration, about 4Ω.

• Insulation resistance between slip ring and ball core:

0.1MΩ or more by 500V megohmmeter.

• Check slip rings for surface. If staind or rough, use

sand paper (#300 - #500).

6D3-19-1.tif

6D3-19-2.tif

6D3-19-3.tif

Tighten the lightly with

a vise with care not to

cause any damage

.

Loading...

Loading...