GENERAL ENGINE MECHANICAL 6A – 53

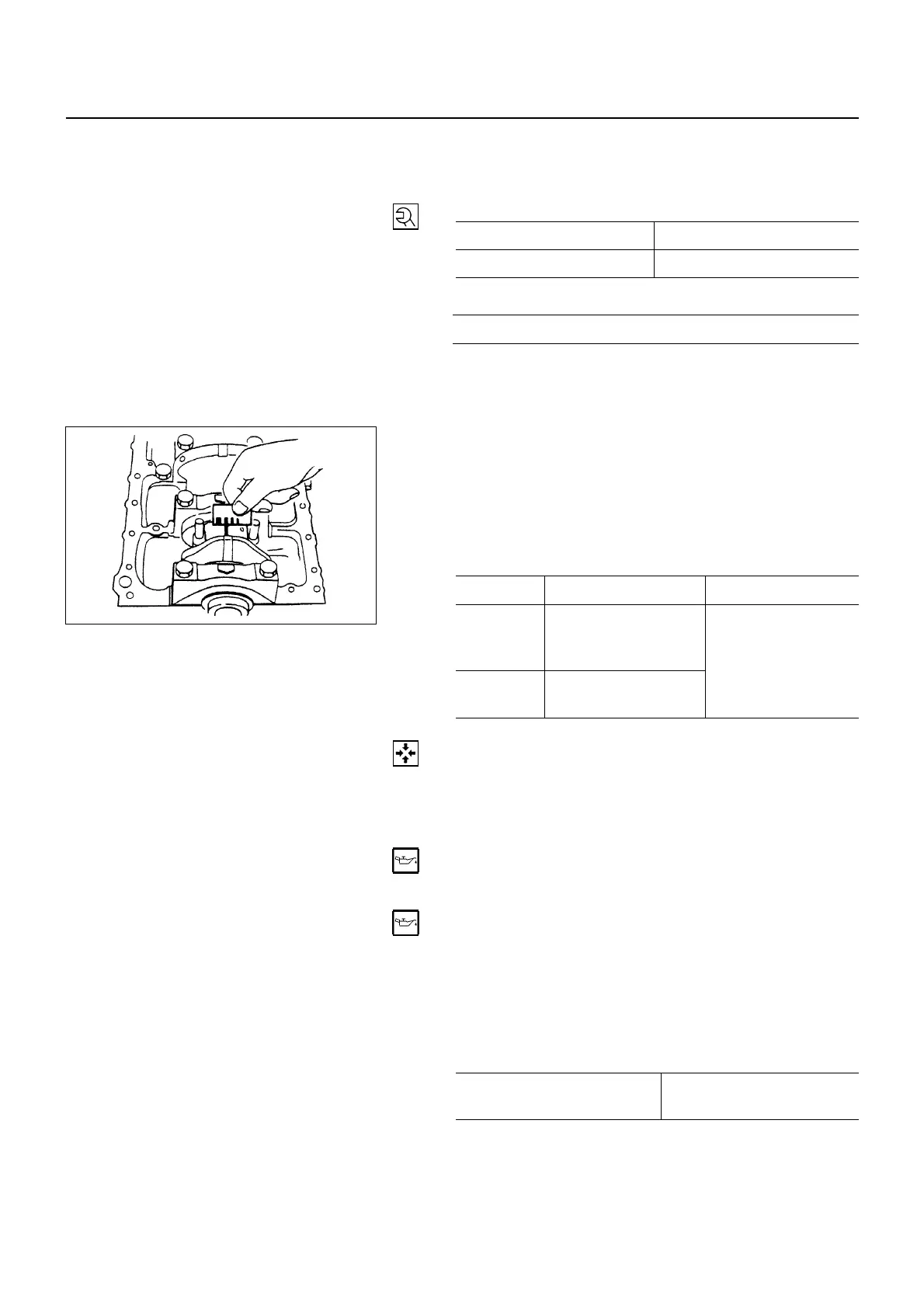

5) Tighten the cap nuts in 2 steps, using angular

tightening method as shown in the following

specifications. (4JG2)

4JG2 N∙m (kg∙m/lb∙ft)

1st Steps 2nd Step

29 (3.0/22) 45° - 75°

4JA1, 4JB1, 4JB1TC N∙m (kg∙m/lb∙ft)

83 (8.5/61)

NOTE:

Do not allow the crankshaft to rotate.

6) Remove the rod caps.

7) Measure the width of the plastigage and determine

the oil clearance. If the oil clearance exceeds the

limit, replace the rod bearings as a set.

8) Clean the plastigage from the bearings and the

crankshaft pins.

Crankshaft Journal and Bearing Clearance mm (in)

Standard Limit

4JB1 /

4JB1T /

4JB1TC

0.029 - 0.066

(0.0011 - 0.0026)

4JG2

0.029 - 0.083

(0.0011 - 0.0033)

0.100 (0.0039)

REASSEMBLY

11. Connecting Rod

10. Piston

9. Piston Pin

Apply a cost of engine oil to the piston pin and the piston

pin hole.

8. Piston Pin Snap Ring

Apply a thin coat of engine oil to the piston pin.

Try to insert the piston pin into the piston pin hole with

normal finger pressure.

Weigh each piston and connecting rod assembly.

Select piston and connecting rod combinations so that the

weight variation of the different assemblies a held within

the specified limits.

g (oz)

Variance in weight

after assembly

Less than 3

(0.1058)

NOTE:

When changing piston/connecting rod combinations,

do not change the piston/piston pin combination

6A-53-1.tif

Loading...

Loading...