6A – 52 GENERAL ENGINE MECHANICAL

Bushing replacement

Removal: Use a suitable bar and bench press or

hammer.

Installation: Use a suitable bar and bench press.

NOTE:

Align the bushing with the connecting rod oil port.

After installing a new bushing, finish the bushing bore

with a pin hole grinder.

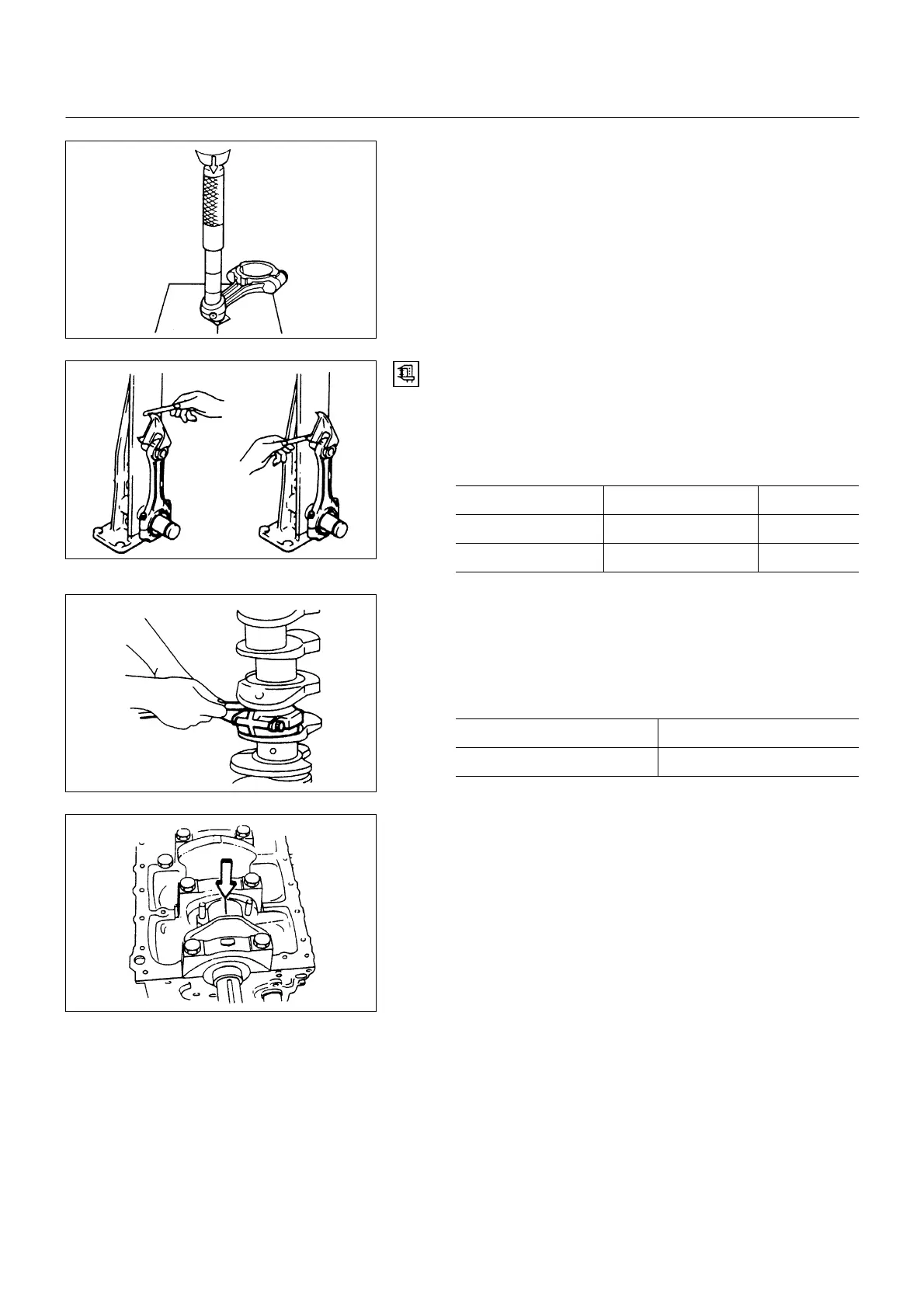

Connecting rods

1. Check the connecting rod alignment with a connecting

rod aligner.

If either the bend or the twist exceeds the specified

limit, the connecting rod must be replaced.

mm (in)

Standard Limit

Bend per 100 (3.94) 0.08 (0.0031) or less 0.20 (0.0079)

Twist per 100 (3.94) 0.05 (0.0020) or less 0.15 (0.0059)

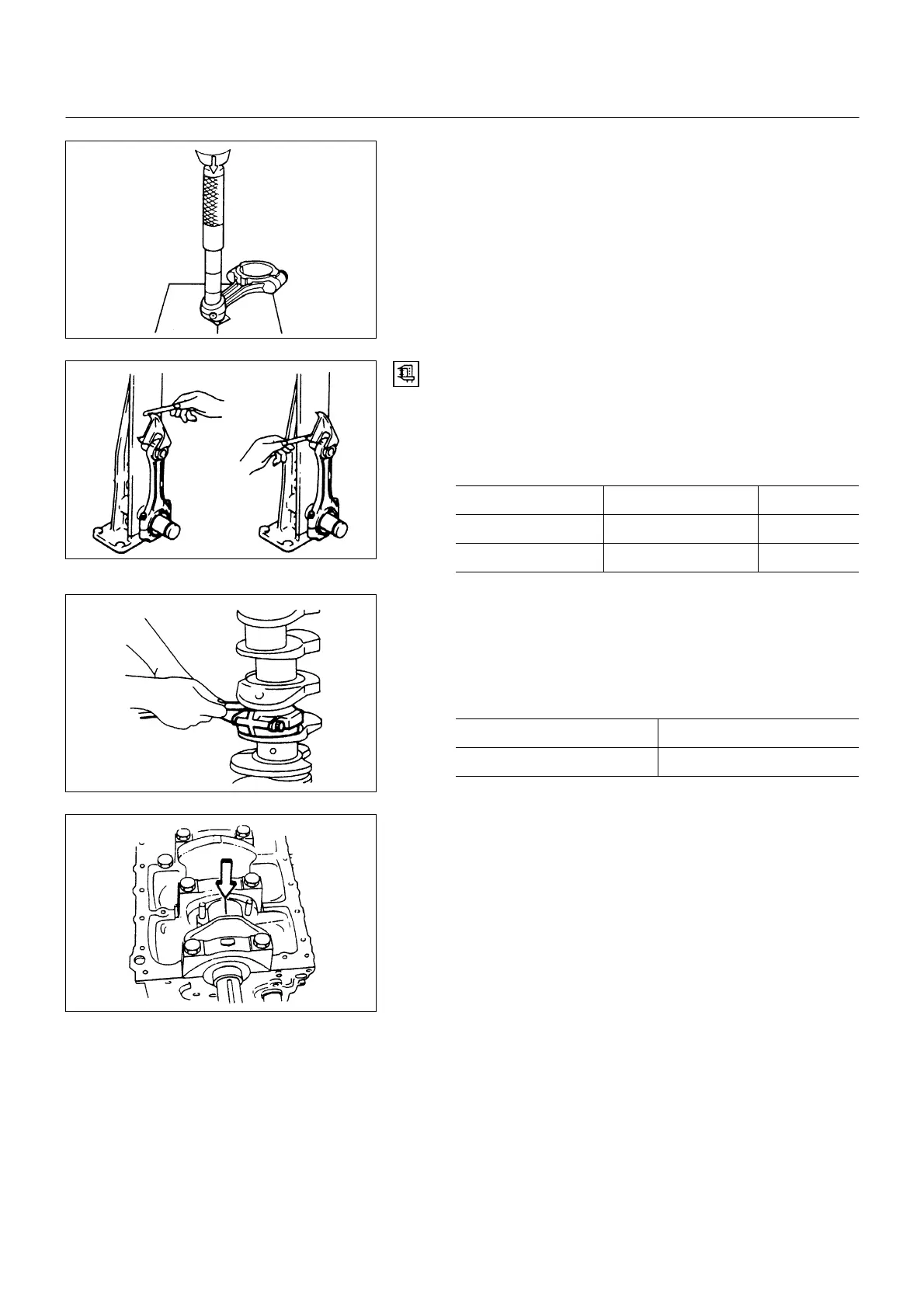

2. Measure the connecting rod thrust clearance.

Use a feeler gauge to measure the thrust clearance at

the big end of the connecting rod.

If the clearance exceeds the specified limit, the

connecting rod must be replaced.

Thrust Clearance mm (in)

Standard Limit

0.230 (0.0091) 0.350 (0.0138)

3. Measure the oil clearance between the connecting rod

and the crankshaft by:

1) Remove the connecting rod cap nuts and the rod

caps.

Arrange the removed rod caps in the cylinder

number order.

2) Clean the rod bearings and the crankshaft pins.

3) Carefully check the rod bearings.

If even one bearing is found to be damaged or

badly worn, the entire bearing assembly must be

replaced as a set. Reinstall the bearings in their

original positions.

Apply plastigage to the crank pin.

4) Reinstall the rod caps to their original positions

6A-52-1.tif

6A-52-2.tif

6A-52-3.tif

6A-52-4.tif

Loading...

Loading...