GENERAL ENGINE MECHANICAL 6A – 51

4JG2 mm (in)

Standard

Limit

1st 0.09-0.13

(0.0035 - 0.0051)

Compression

ring

2nd 0.05 - 0.07

(0.0020 - 0.0028)

Oil ring

0.03-0.07

(0.0012-0.0028)

0.15

(0.0059)

Piston pin

Visually inspect the piston pin for cracks, flaws, and other

damage and replace if necessary.

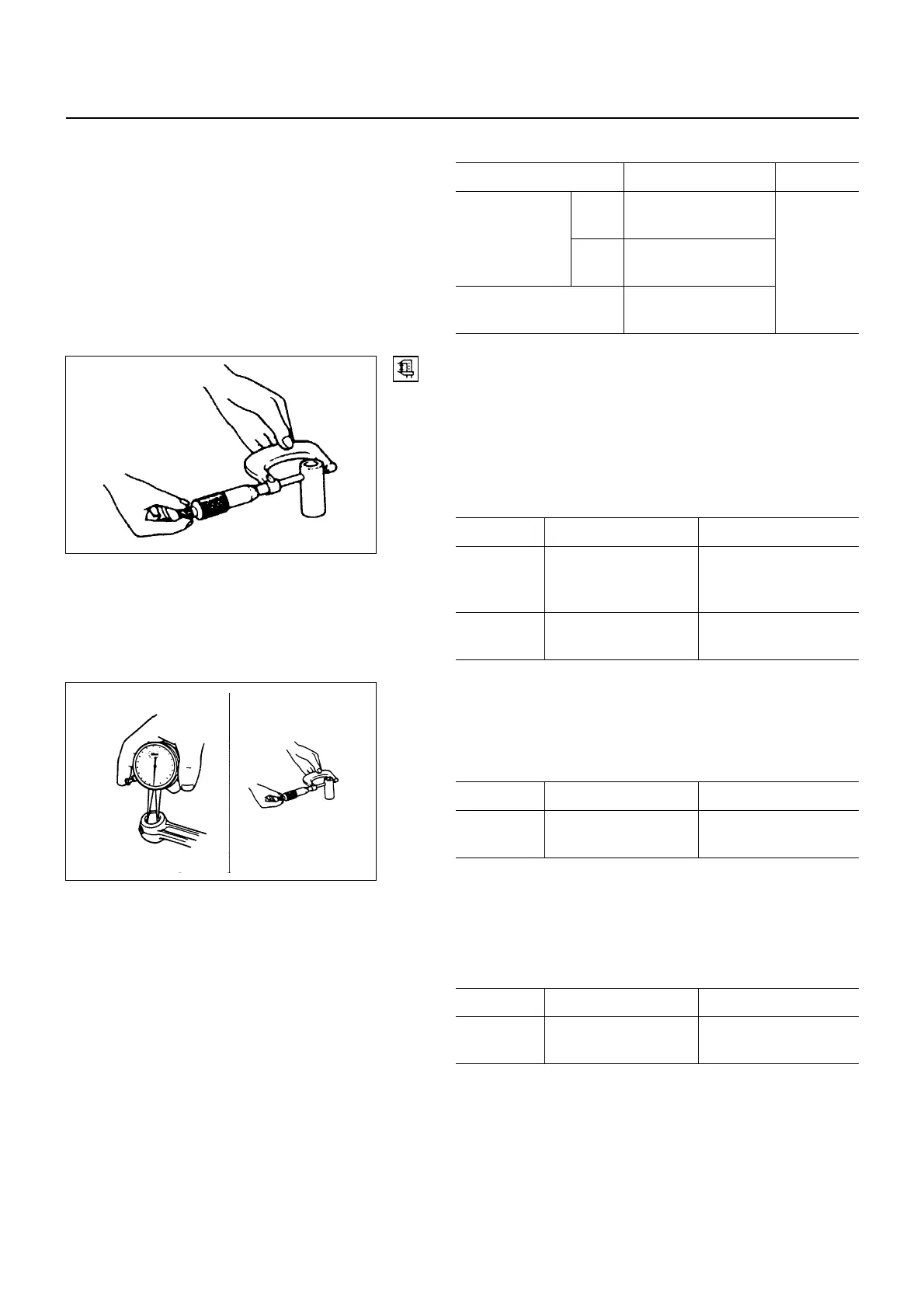

1. Use a micrometer to measure the piston pin outside

diameter in both directions at three different positions.

If the measurement exceed the specified limit the

piston pin must be replaced.

Piston pin outside diameter mm (in)

Standard Limit

4JB1 /

4JB1T

4JB1TC

30.995 - 31.000

(1.2202 - 1.2204)

30.970 (1.2190)

4JG2

33.995 - 34.000

(1.3384 - 1.3386)

33.970 (1.3374)

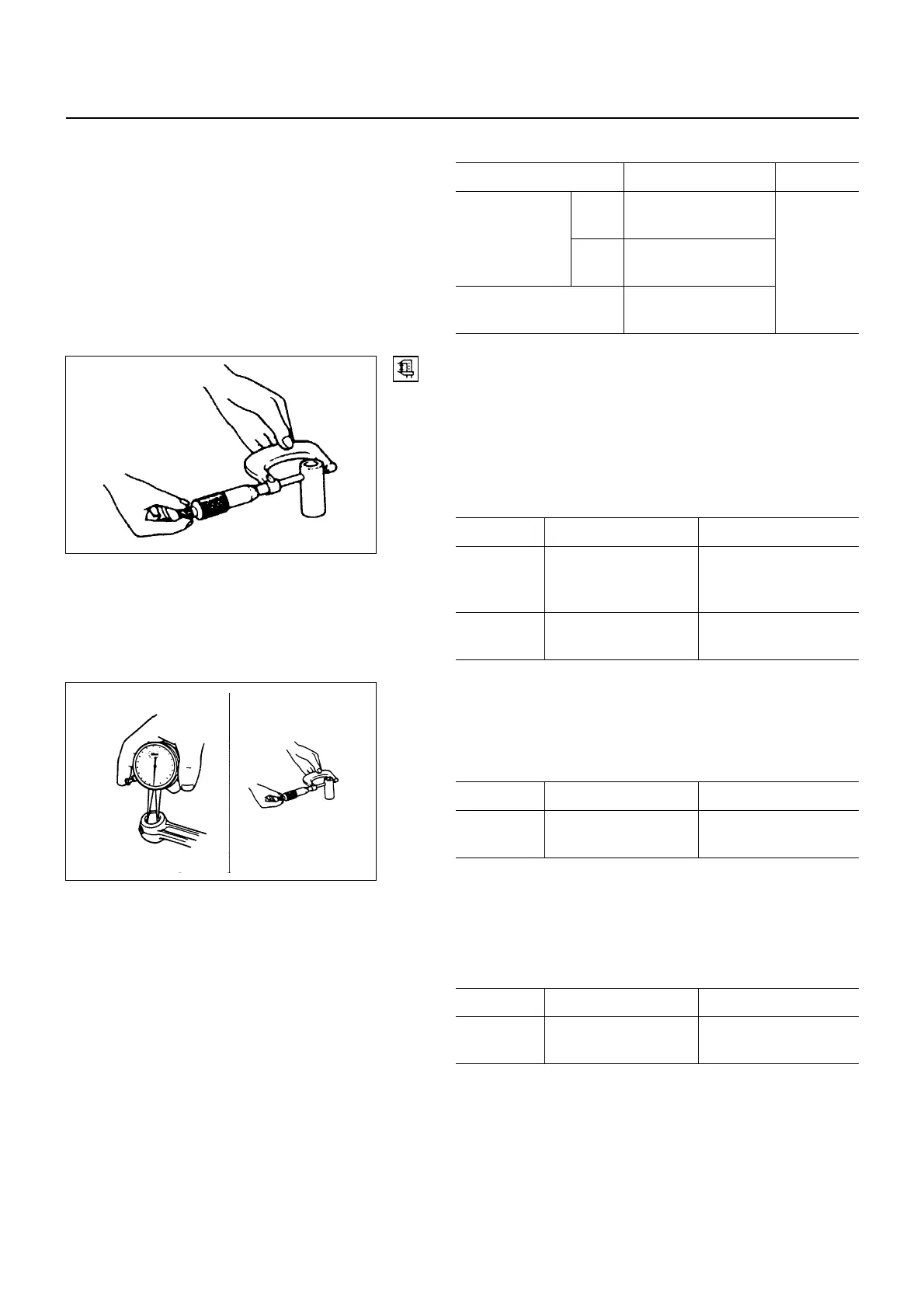

2. Measure the inside diameter of the connecting rod

small end. If the clearance between the small end and

pin does not conform to the specified value, the

connecting rod or bushing and pin must be replaced.

mm (in)

Standard Limit

Clearance

0.008 - 0.020

(0.0003 - 0.0008)

0.05

(0.0020)

3. Insert the piston pin into the piston and rotate it. If the

pin rotates smoothly with no backlash, the clearance is

normal. If there is backlash or roughness, measure the

clearance. If the clearance exceeds the specified limit,

the piston and the piston pin must be replaced.

mm (in)

Standard Limit

Clearance

0.002 - 0.004

(0.00008 - 0.00016)

0.04

(0.0016)

6A-51-1.tif

6A-51-2.tif

Loading...

Loading...