6A – 50 GENERAL ENGINE MECHANICAL

NOTE:

It is most important that the correct piston grade be

used. Failure to select the correct piston grade will

result in engine failure. Always measure the cylinder

bore and select the correct piston grade.

Piston rings

Any worn or damaged part discovered during engine

overhaul must be replaced with a new one.

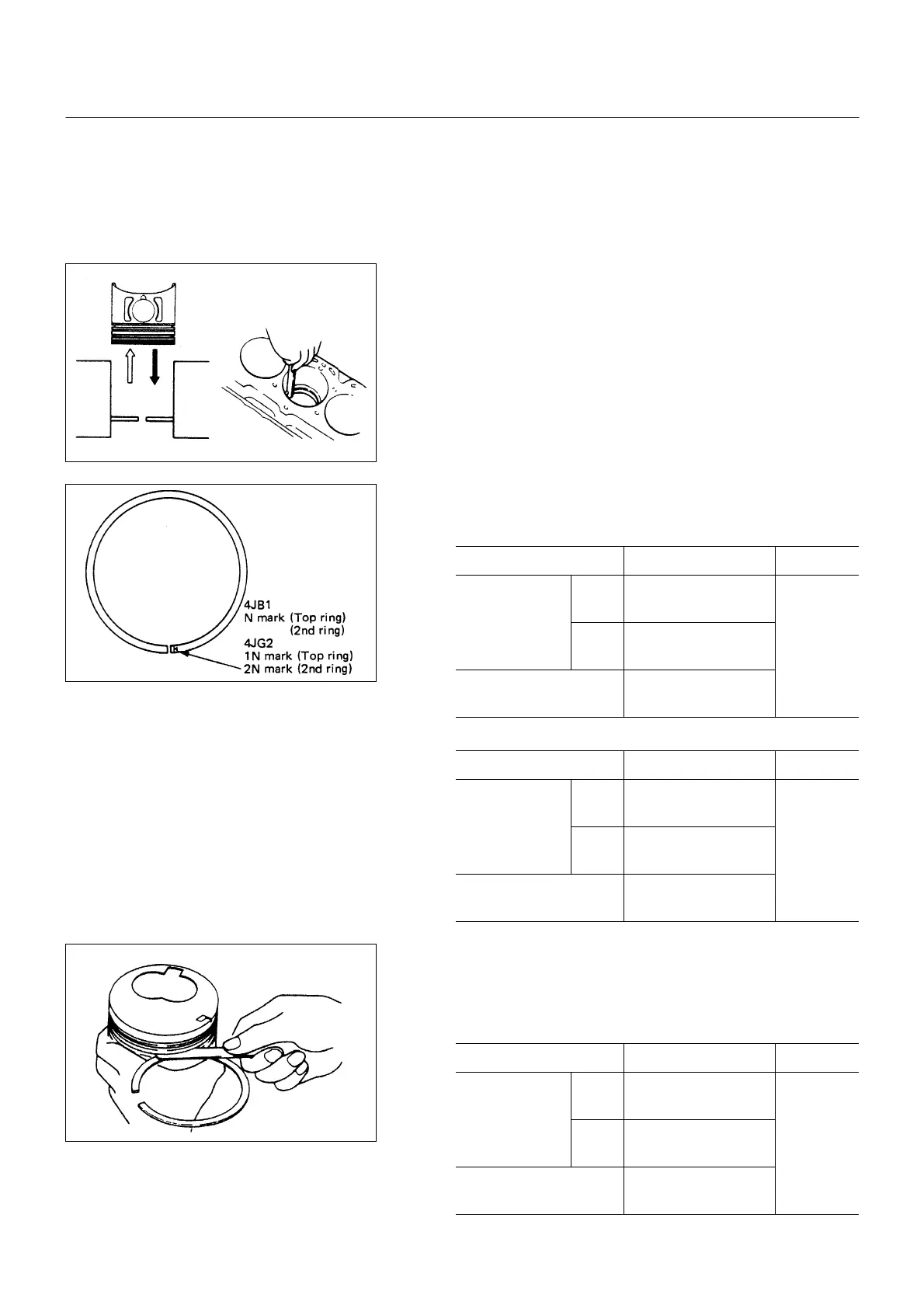

1. Ring end gap measurement

• Insert the piston ring into the bore.

• Push the ring by the piston, at a right angle to the wall,

into the point ring at which the cylinder bore diameter

is the smallest.

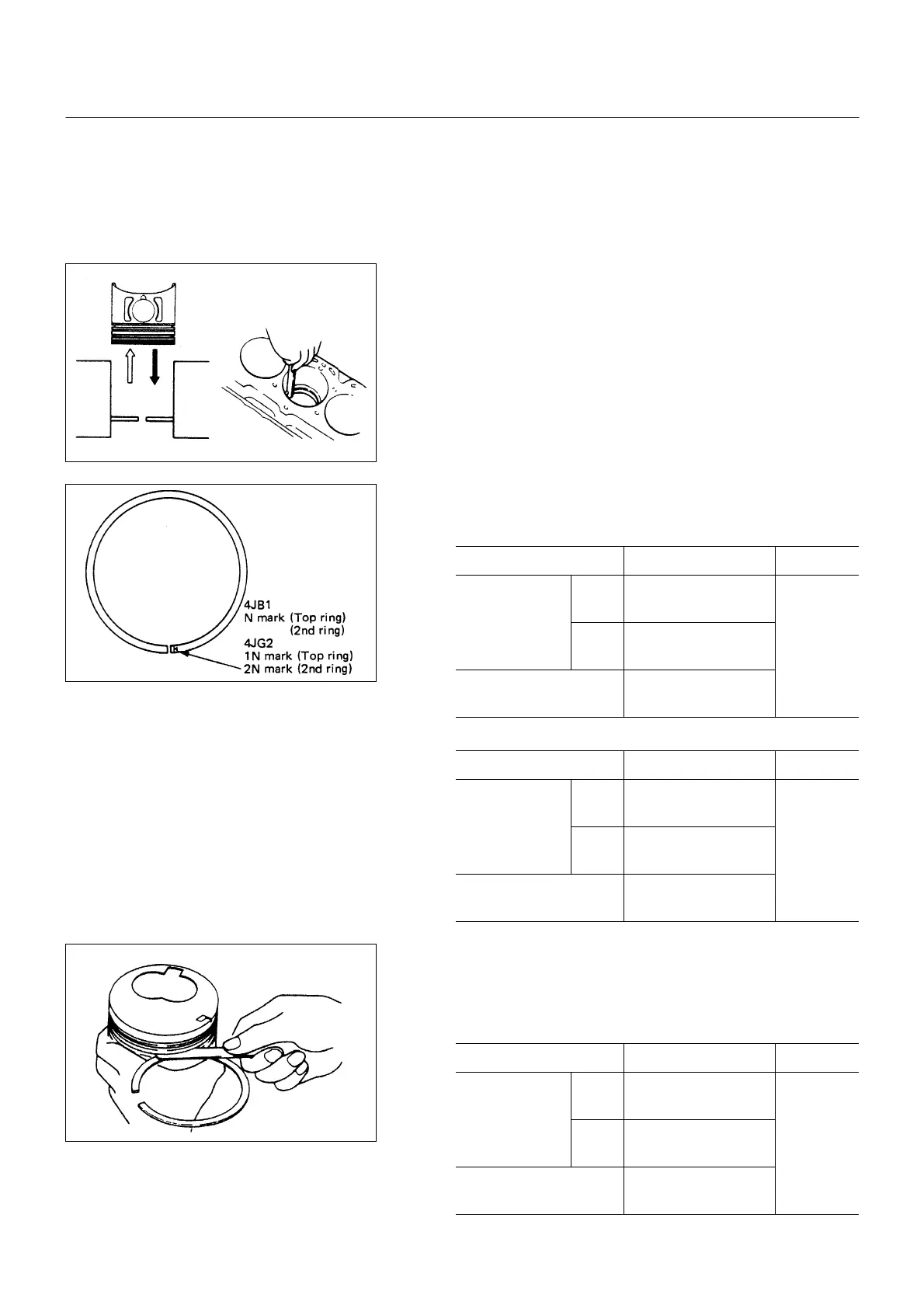

• The top mark of the piston ring are shown in the

illustration.

4JB1 / 4JB1T / 4JB1TC mm.(in)

Standard Limit

1st 0.20 - 0.40

(0.0079 - 0.0157)

Compression

ring

2nd 0.20 - 0.40

(0.0079- 0.0157)

Oil ring

0.10 - 0.30

(0.0039 - 0.0118)

1.5

(0.059)

4JG2 mm.(in)

Standard Limit

1st 0.20 - 0.35

(0.0079 - 0.0138)

Compression

ring

2nd 0.37 - 0.52

(0.0146 - 0.0205)

Oil ring

0.20 - 0.40

(0.0079 - 0.0157)

1.5

(0.059)

2. Measure the clearance between the piston ring groove

and the piston ring with a feeler gauge. If the piston

ring groove/piston ring clearance exceeds the

specified limit, the piston must be replaced.

4JB1 / 4JB1T / 4JB1TC mm (in)

Standard Limit

1st 0.090 - 0.125

(0.0035 - 0.0049)

Compression

ring

2nd 0.050 - 0.075

(0.0020 - 0.0030)

Oil ring

0.03 - 0.07

(0.0012 - 0.0028)

0.15

(0.0059)

6A-50-1.tif

6A-50-2.tif

6A-50-3.tif

Loading...

Loading...