6C - 22 ENGINE FUEL

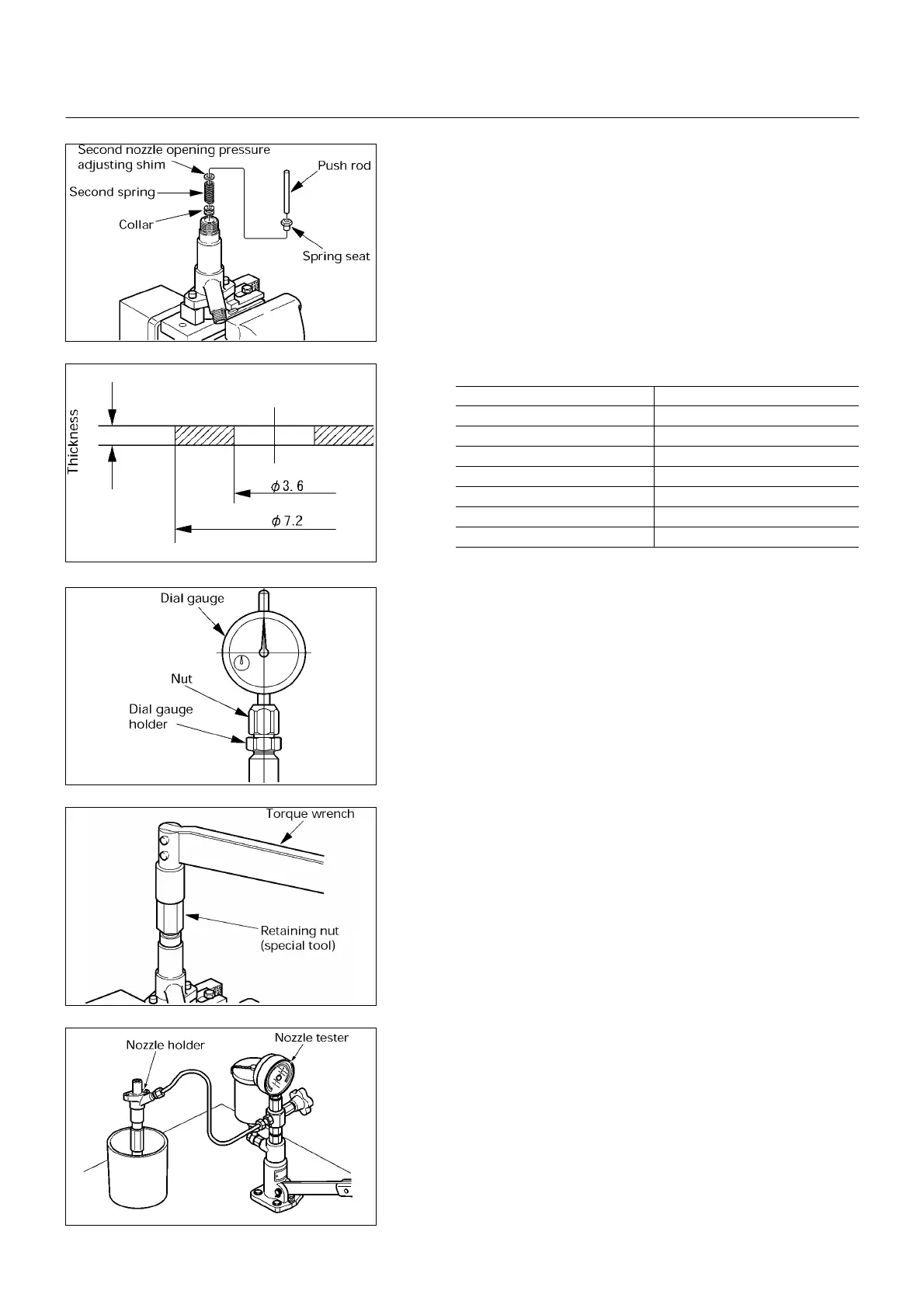

Second nozzle opening pressure adjustment

If the second nozzle opening pressure is not as specified,

disassemble the nozzle from the nozzle holder and

replace the shim until the pressure is as specified.

CAUTION:

• Because the second opening pressure changes

when the first opening pressure changes, the

second opening pressure must be adjusted when

the first opening pressure changes.

• Use a micrometer to measure shim thickness.

• Second nozzle opening pressure adjusting shims

Part No. Thickness (mm)

8-9711-6034-0 0.40

8-9711-6035-0 0.50

8-9711-6037-0 0.52

8-9711-6039-0 0.54

8-9711-6041-0 0.56

8-9711-6043-0 0.58

8-9711-6044-0 0.59

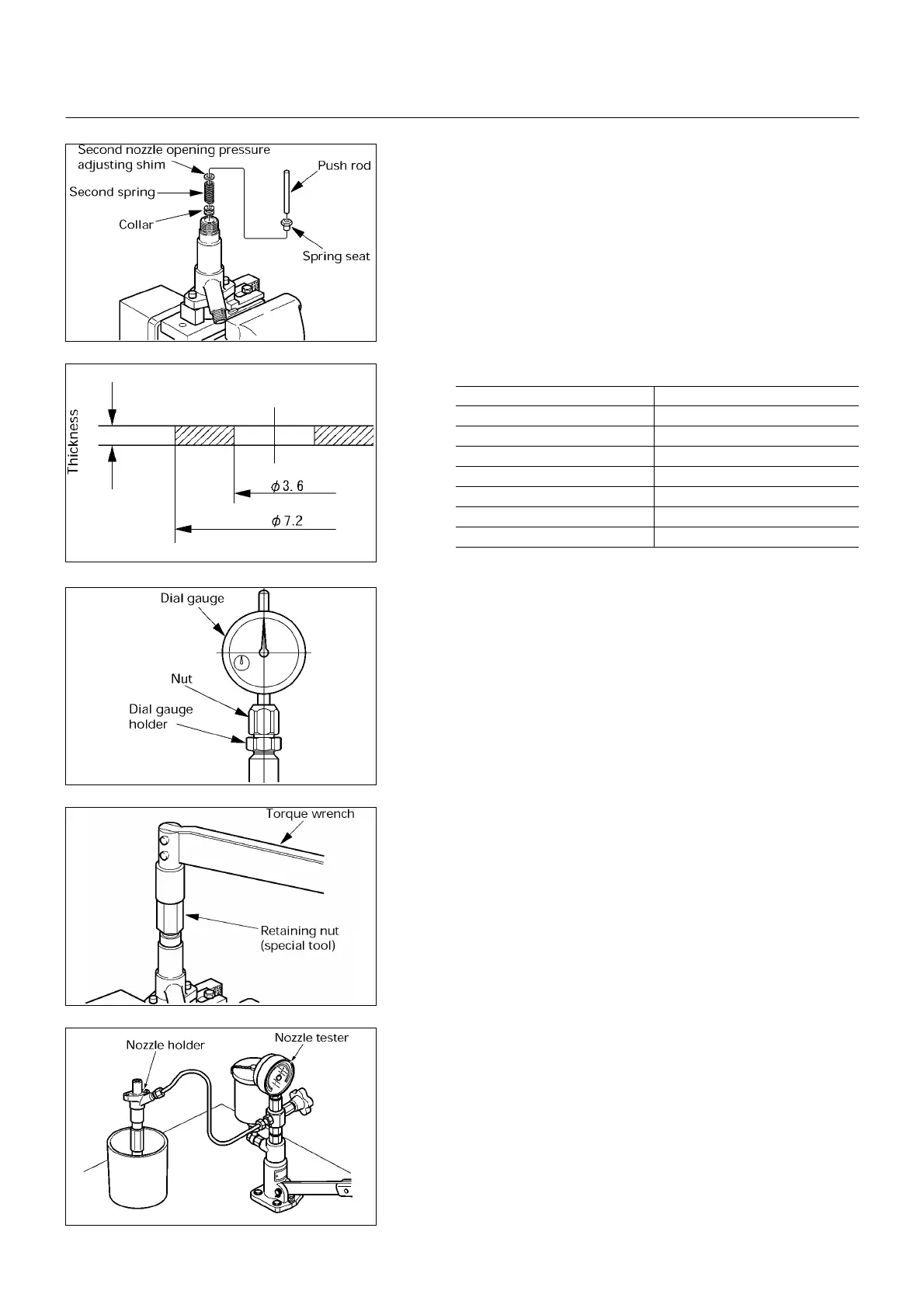

Final inspection

1. Remove the dial gauge, nut and dial gauge holder.

2. Remove the adjustment retaining nut and gasket.

3. Install the original retaining nut, confirm that the pins

are inserted fully into the nozzle, and then hand-tighten

the retaining nut. Then, tighten the original retaining

nut to the specified torque.

Torque: 59 - 79 N∙m (6.0 - 8.0 kg∙m)

4. Set the nozzle holder to the nozzle tester and check

first nozzle opening pressure, spray condition, seat oil

tightness and each part for oil leaks.

5. When replacing the nozzle, replace the nozzle, lift

piece, pins and spacer as a set with the nozzle service

kit.

CAUTION:

Pre-lift will not be as specified if only the nozzle is

replaced.

040MV017.tif

040LX009.tif

040MV028.tif

040MV014-1.tif

040MV030.tif

Loading...

Loading...