00 – 48 SERVICE INFORMATION

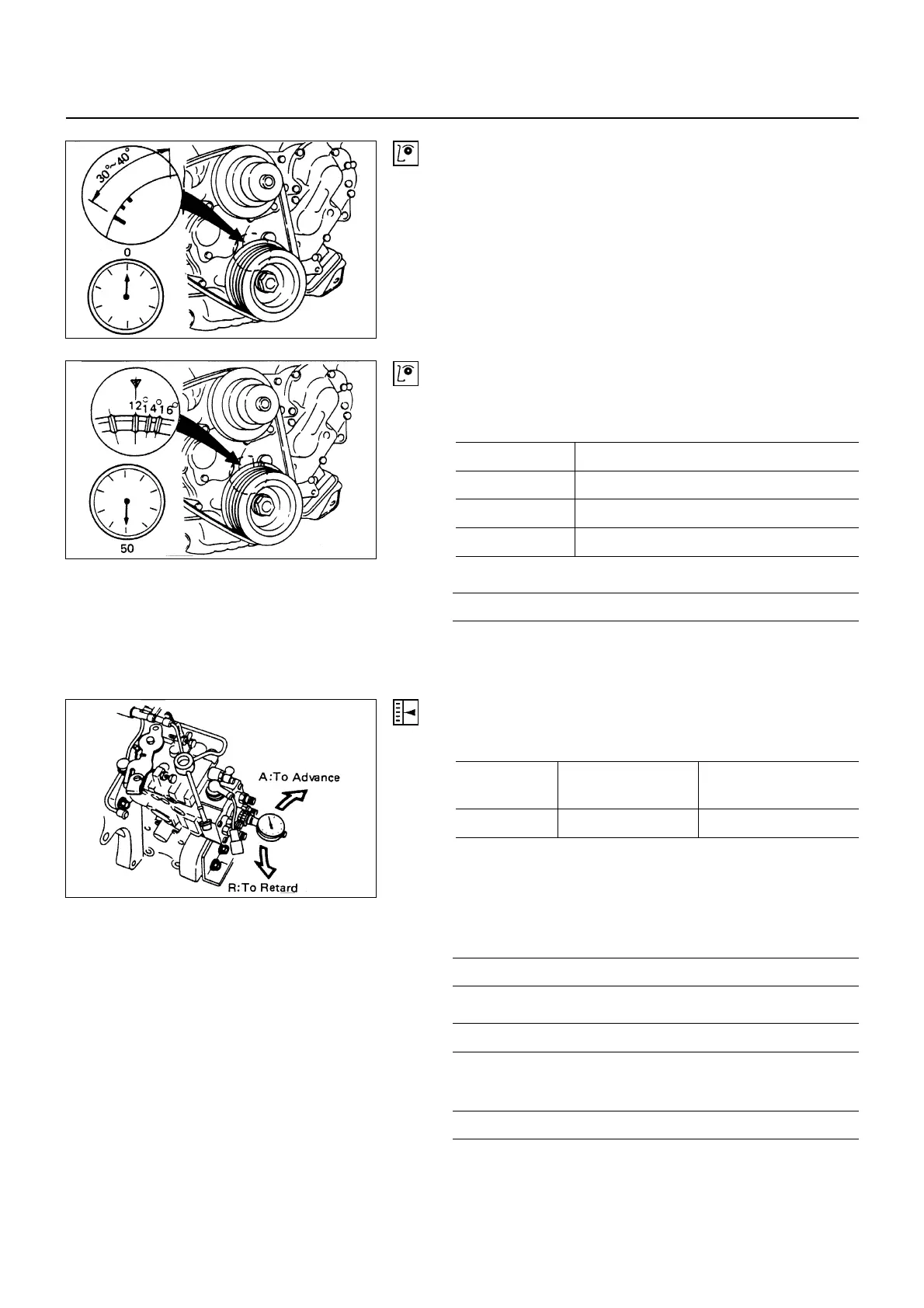

7. Rotate the crankshaft to bring the piston in the No. 1

cylinder to a point 30 - 40° BTDC.

8. Set the timing gauge needle to zero.

9. Move the crankshaft pulley slightly in both directions

to check that the gauge indication is stable.

10. Turn the crankshaft clockwise and read the gauge

indication when the crankshaft pulley timing mark is

aligned with the pointer.

mm (in)

4JB1 BTDC 14°

4JB1T BTDC 11°

4JB1TC BTDC 4°

4JG2 ATDC 2°

Standard Reading mm (in)

0.5 (0.02)

If the injection timing is outside the specified range,

continue with the following steps.

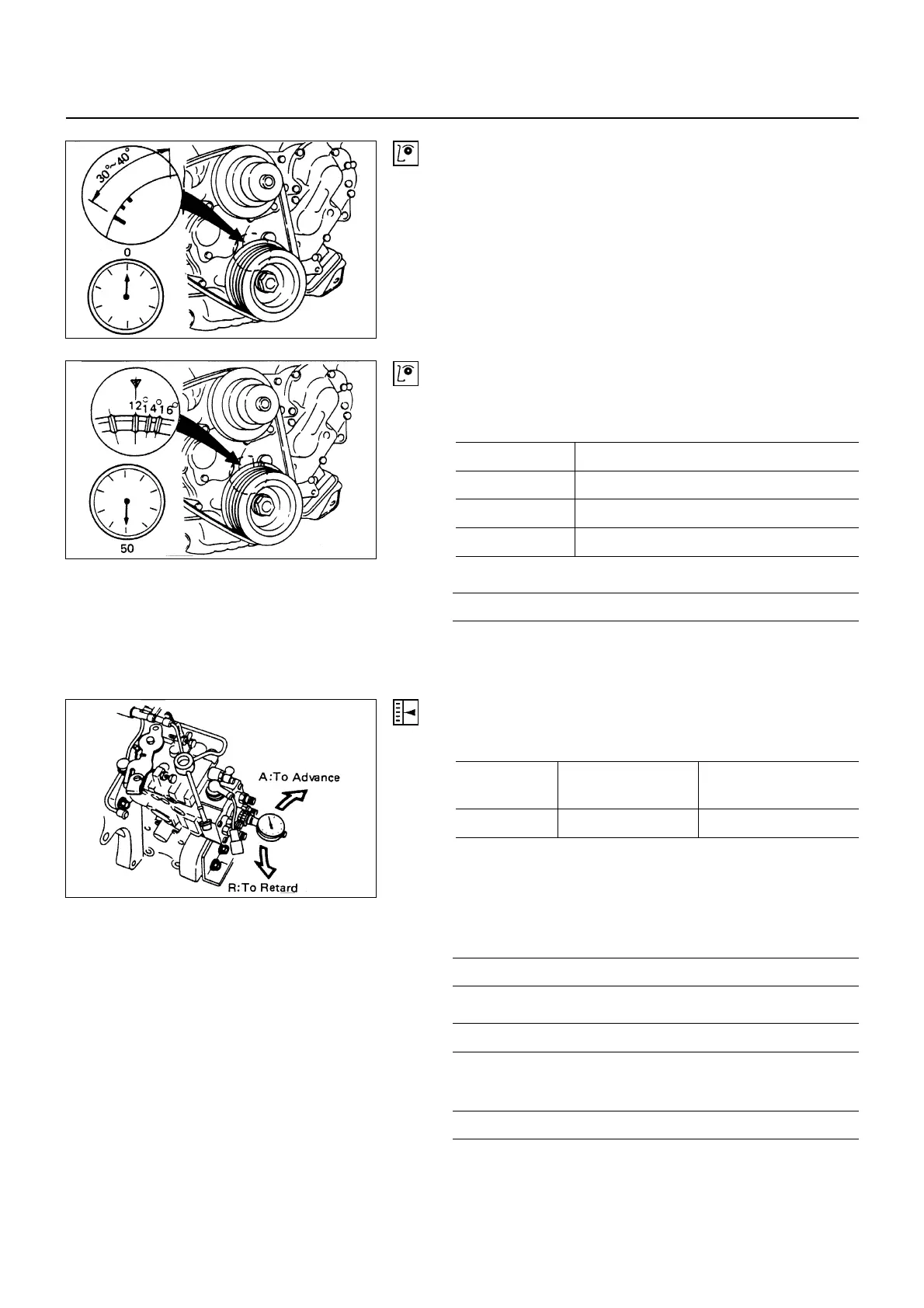

11. Loosen the injection pump fixing nuts and bracket

bolts.

12. Adjust the injection pump setting angle.

When large than

standard value

When smaller than

standard value

Gear drive A B

A : Move the injection pump toward the engine.

B : Move the injection pump away from the engine.

Tighten the pump fixing nut, adjust bolt and pump

distributor head plug to the specified torque.

Pump Fixing Bolt N∙m (kg∙m/lb∙ft)

24 (2.4/17)

Adjust Bolt N∙m (kg∙m/lb∙ft)

19 (1.9/14)

Injection Pump

Distributor Head Plug N∙m (kg∙m/lb∙ft)

17 (1.7/12)

CAUTION

• When installing the distributor head/plug, be sure

to use new copper washer.

0047-1.tif

0047-2.tif

0047-3.tif

Loading...

Loading...