53

6. Maintenance

6.4. Locking torque for bolted assemblies

Attention!

All bolted assemblies especially of the knife and of the chassis should be checked

regularly, retighten if necessary. Unless otherwise noted the following locking torques

apply.

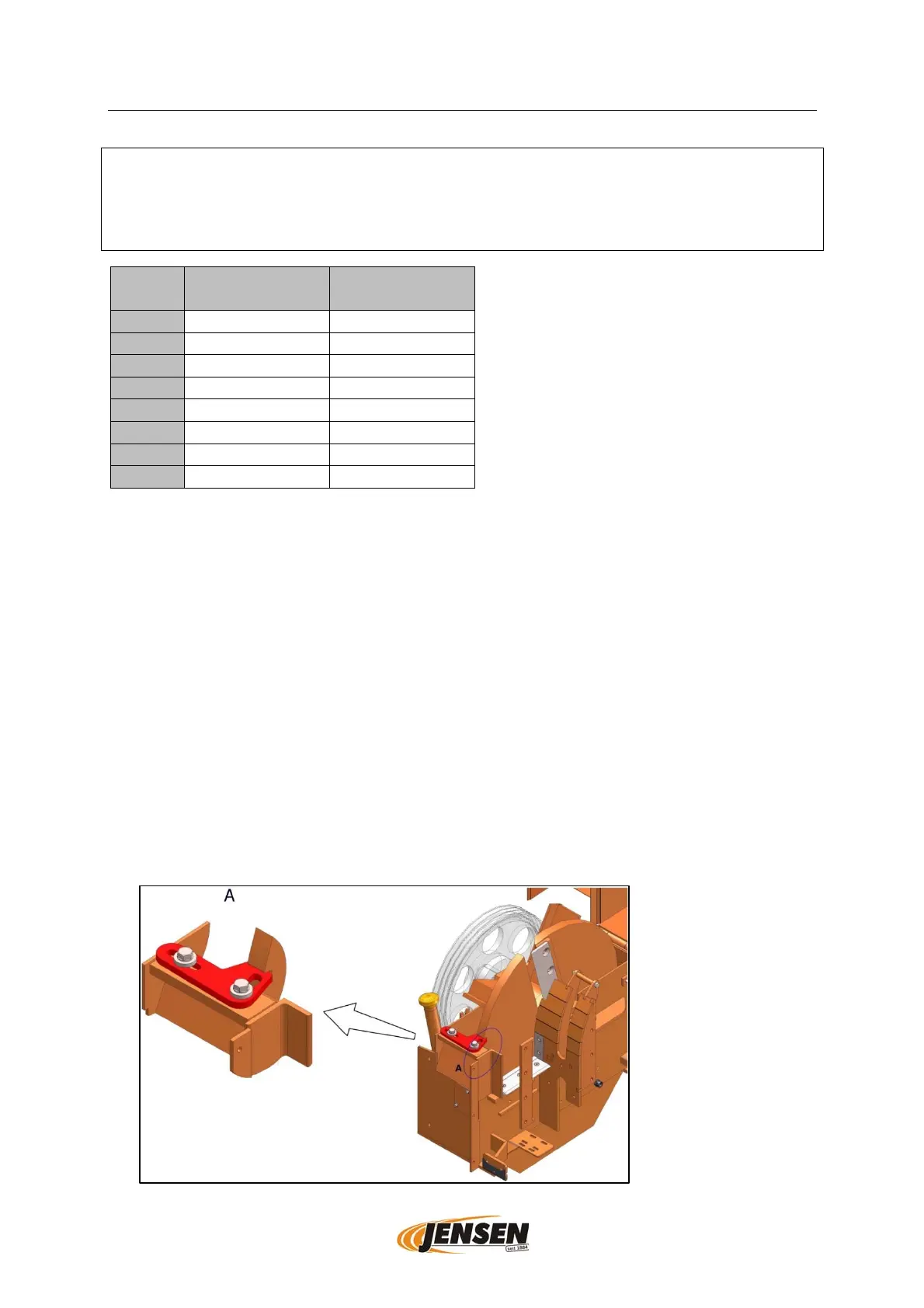

thread

locking torque

8.8

Nm

locking torque

10.9

Nm

M6 10 14,5

M8 25 35

M10 49 72

M12 86 125

M16 210 310

M20 410 610

M24 710 1050

¾“ 410

6.5. Maintenance of the cutting tools

Blunt knifes can affect the quality of the wood chips negatively.

If necessary the cutting tools can be re-sharpened or changed.

Important!

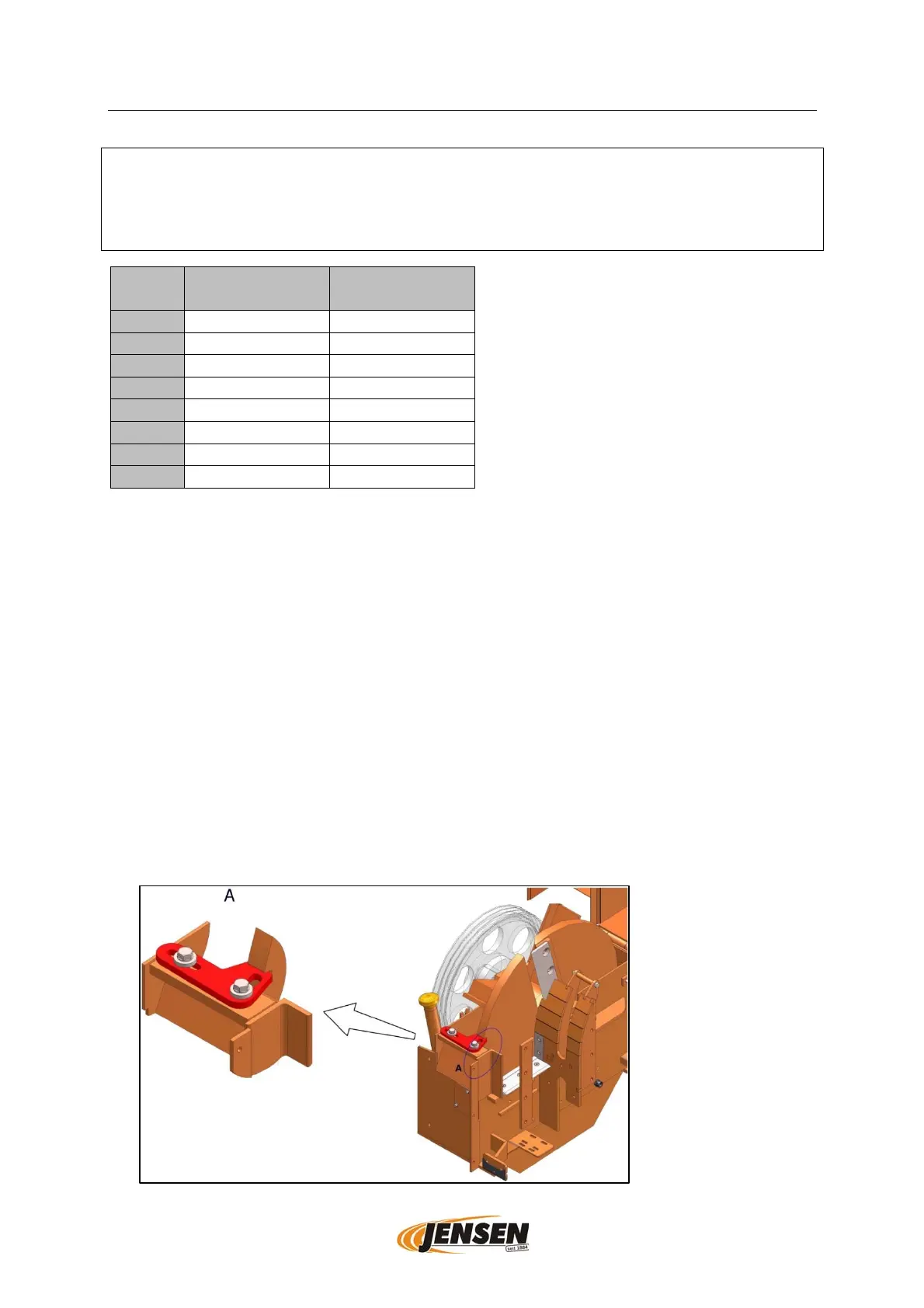

1. Block the knife disk with the provided blocking tool before changing the knives.

Use the bolts of the ejector cap (see picture).

2. Always keep the cutting unit in a sharp condition to guarantee an efficient and

slightly cut.

3. Do not grab the knife on the blade side – Danger of injury!

4. Attention! Excessive wear out of the cutting unit can cause a total loss of the

cutting unit.

5. Pay attention for the operating condition: the condition of the material can affect

the durability of the cutting tools (clean fresh wood or with abrasive materials

attached material).

Knife disk blocking tool schematic display, differences in design and type possible.

Loading...

Loading...