50 of 76

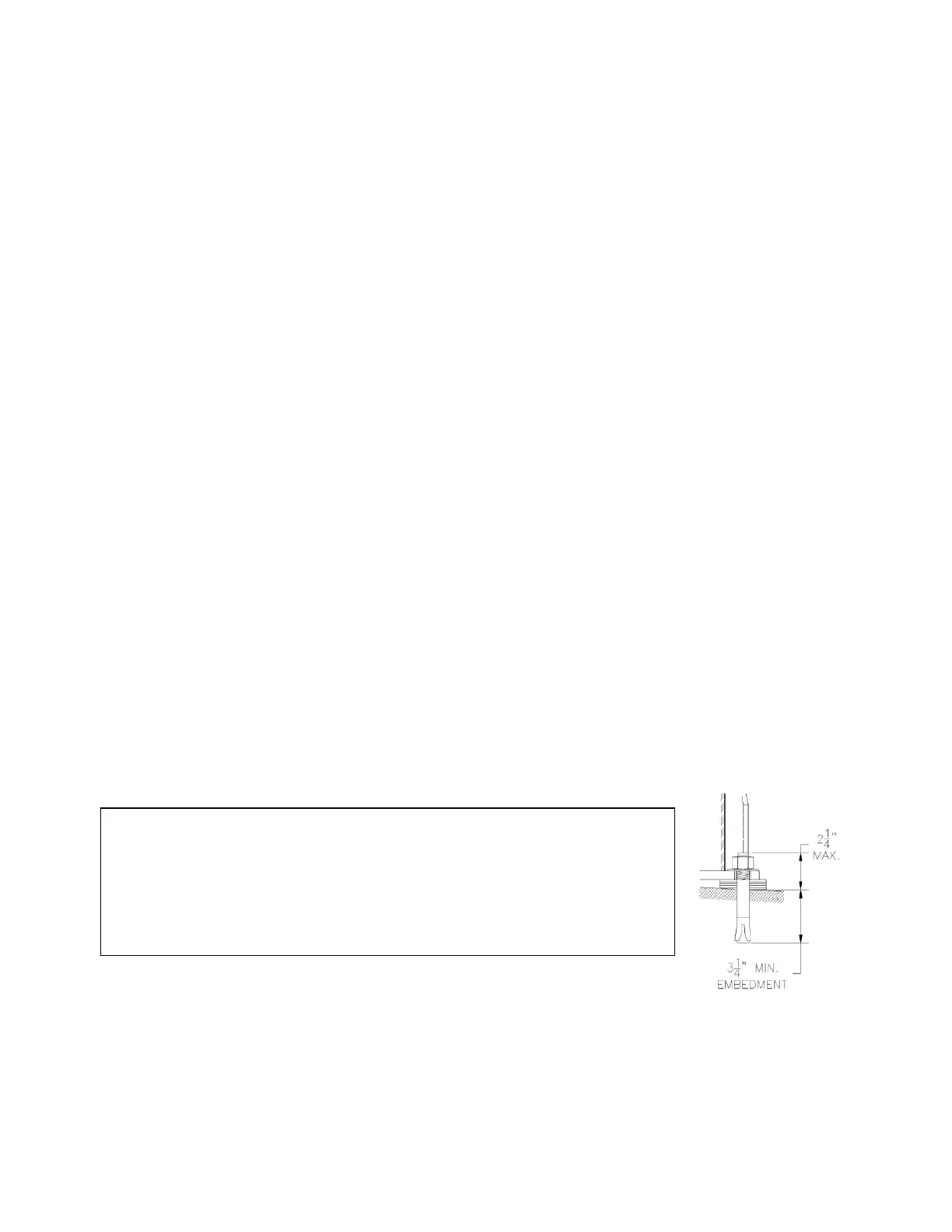

NOTE: The 3/4” 5½” lg. wedge anchor bolts supplied must have

a minimum embedment of 3¼” into concrete floor.

NOTE: If anchors do not tighten to required torque, OR project

more than 1½” above the concrete surface due to floor slope,

contact a foundation engineer to determine the best course of

10.11 RUNWAYS

10.11.1 Check Runways

Check level of runways on the floor, on the locks and on the cables: Refer to

Section 6.10. Adjust as required.

Check runways for damage or abnormal deformation. If such conditions exist,

contact Snap-on Equipment Technical Support.

10.11.2 Inspect Jackbeam Tracks

Inspect rolling jack / oil drain pan tracks for cleanliness, corrosion, excessive

wear or damage.

Clean dirty tracks.

Worn or damaged tracks should be repaired immediately.

10.12 COLUMNS

10.12.1 Check Columns

Check columns for corrosion, giving special attention to the area at the base of

the column.

Check severely corroded areas by pecking with an awl or welder’s chipping

hammer.

If column is corroded through at any point, it must be replaced immediately.

If not corroded through, remove old paint and rust scale, then coat with a high

quality corrosion resistant paint. Clean and lubricate glide blocks.

10.12.2 Check Column Anchors

Check column anchor bolts for tightness (if loose, re-torque to 110 ft-lb). If

anchors do not tighten to required torque, or continue to loosen, contact Snap-on

Equipment Technical Support.

Verify proper embedment of anchors after tightening.

10.13 APPROACH RAMPS, CHOCKS, FRONT WHEEL STOPS

Inspect for excessive wear or damage. Repair or replace if required.

Inspect hinge pins. Replace if excessively worn. Lubricate if in good condition

Loading...

Loading...