Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2020.10_2020.11

121/168

Installation instructions

7.27 BPU coupling installation procedure

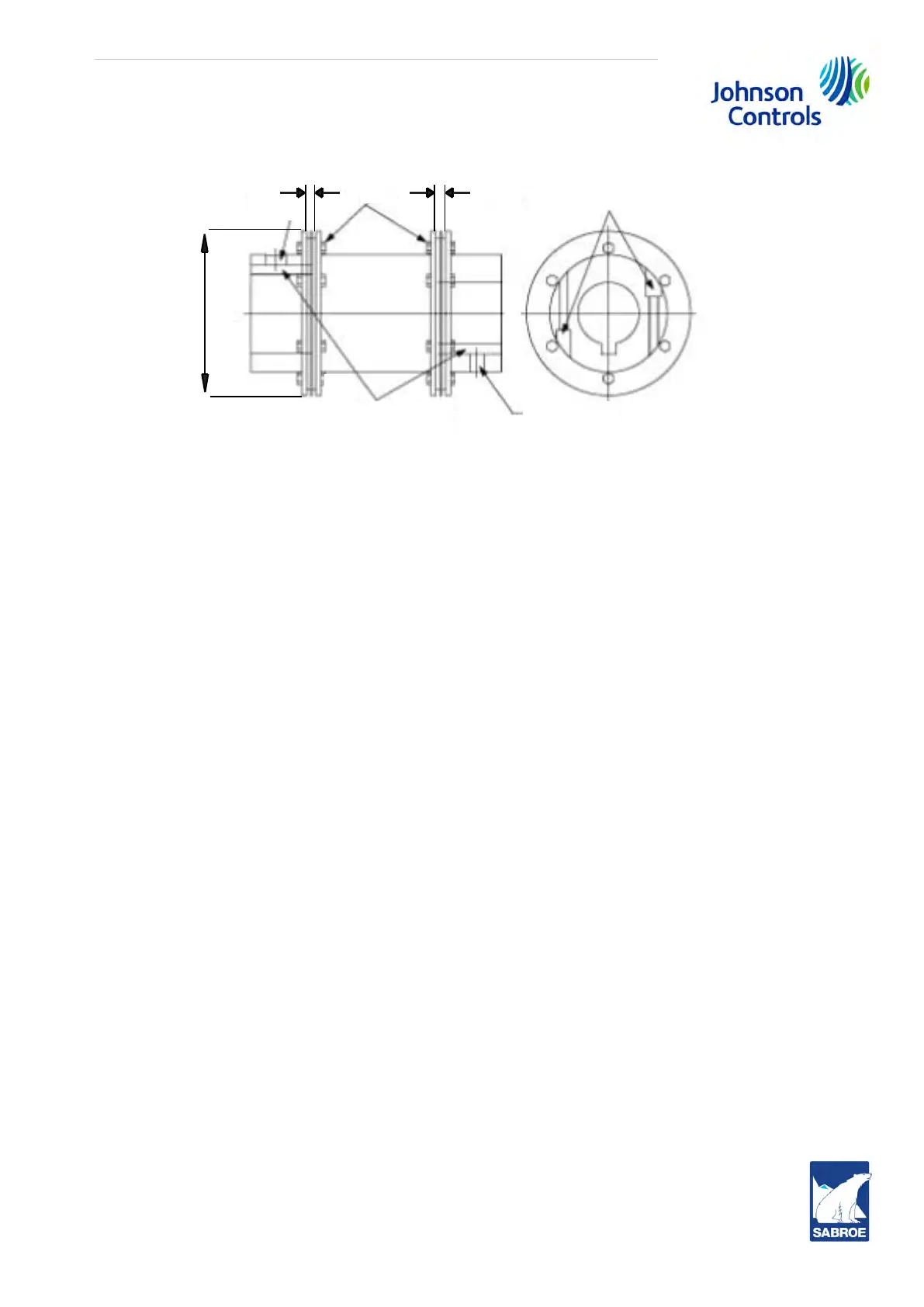

Fig. 83

1. Inspect shafts and hubs to make sure they are free from burrs.

2. Fit the key to the shaft.

Note: Never tighten the clamp bolts without the hub mounted onto the appropriately sized

shaft. Also, do not tighten the set screw before the clamp bolts. Make sure it is not engaging

the top of the key before proceeding to step 3.

Apply a light oil film on all contact surfaces. Do not use any oil with molibdenum bisulphite or

high-pressure additives and do not use grease. These substances notably reduce the friction

coefficient.

3. With the clamp bolts loose and the set screw slightly unscrewed, install the motor and

compressor coupling hubs and key on their respective shafts.

4. Make sure they can slide horizontally so that once the disc packs are installed, no axial

stress is transferred to the disc packs by a stuck coupling hub.

5. Rotate both hubs so that the keys are 180 degrees opposite each other.

6. With the hubs mounted and the axial spacing set, proceed to place the spacer between

the two hub flanges. Be careful when handling the spacer.

Make sure the spacer is fully supported.

If the spacer is not fully supported, the unitised flex discs may be damaged after

installation.

7. Install the unitised flex disc now.

Make sure that all bolt threads are clean and lightly oiled.

8. Start a bolt through a bolt hole in the spacer.

9. Put the unitised flex disc between the hub and spacer until a bushing hole in the unitised

flex disc lines up with the bolt.

10. Slide the bolt through the bushing hole in the unitised flex disc.

11. Install the lock nut until it is snug.

Do not torque any lock nuts at this time.

12. The remaining bolts for this end of the coupling can be installed through the hub bolt holes

and flex disc bushing holes.

Set

Disc pack

Hub clamping bolts

Set screw

Keyways located

180° opposite

lock nuts

screw

G G

A

Loading...

Loading...