Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2020.10

89/168

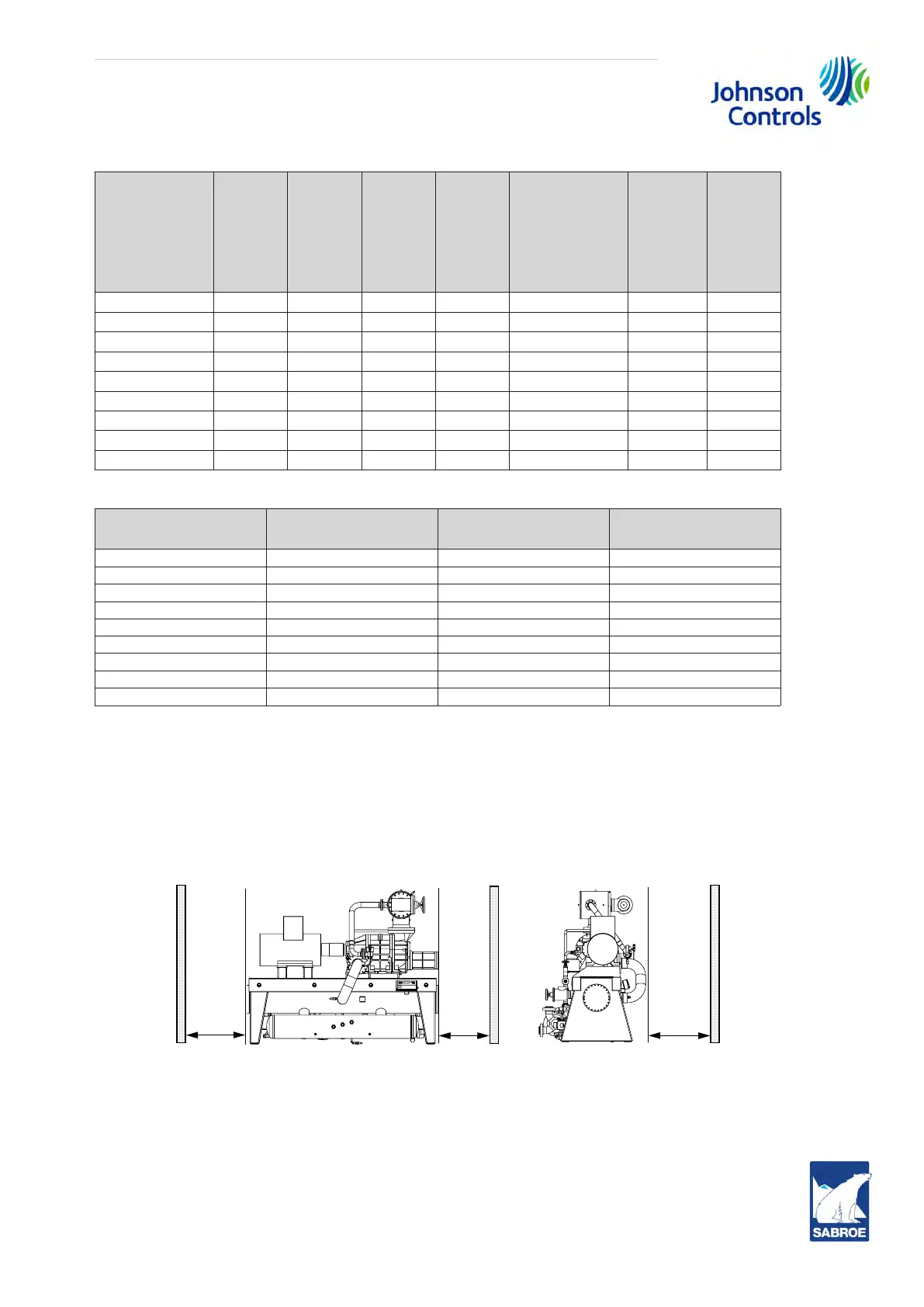

Technical data

Compr.

model

Rotor

dia.

mm

Rotor

L/D

Min.

Speed

rpm

Max.

Speed

rpm

Geometrical

swept

volume

drive shaft

end

Ft

3

/Rev. M

3

/Rev.

M

3

/H

2950

rpm

SGC 1913 193 1.35 1,000 3,600 0.16653 0.004713 834

SGC 1918 193 1.8 1,000 3,600 0.22204 0.006284 1,112

SGC 2313 233 1.35 1,000 3,600 0.29301 0.008292 1,468

SGC 2317 233 1.7 1,000 3,600 0.36897 0.010442 1,848

SGC 2321 233 2.1 1,000 3,600 0.45580 0.012899 2,283

SGC 2813 283 1.35 1,000 3,600 0.52501 0.014858 2,630

SGC 2817 283 1.7 1,000 3,600 0.66115 0.018711 3,312

SGC 2821 283 2.1 1,000 3,600 0.79546 0.022512 3,985

SGC 2824 283 2.4 1,000 3,600 0.89858 0.025430 4,501

Table 20: Geometrical swept volume

Compressor

SAB

Compressor

SGC

Approx. weight

lbs.

Approx. weight

kg

SAB 193 S SGC 1913 1720 780

SAB 193 L SGC 1918 1895 860

SAB 233 S SGC 2313 2670 1210

SAB 233 L SGC 2317 2950 1340

SAB 233 E SGC 2321 3300 1500

SAB 283 S SGC 2813 4100 1860

SAB 283 L SGC 2817 4400 2000

SAB 283 E SGC 2821 4700 2136

SAB 283 X SGC 2824 5100 2315

Table 21: Compressor weight (without coupling)

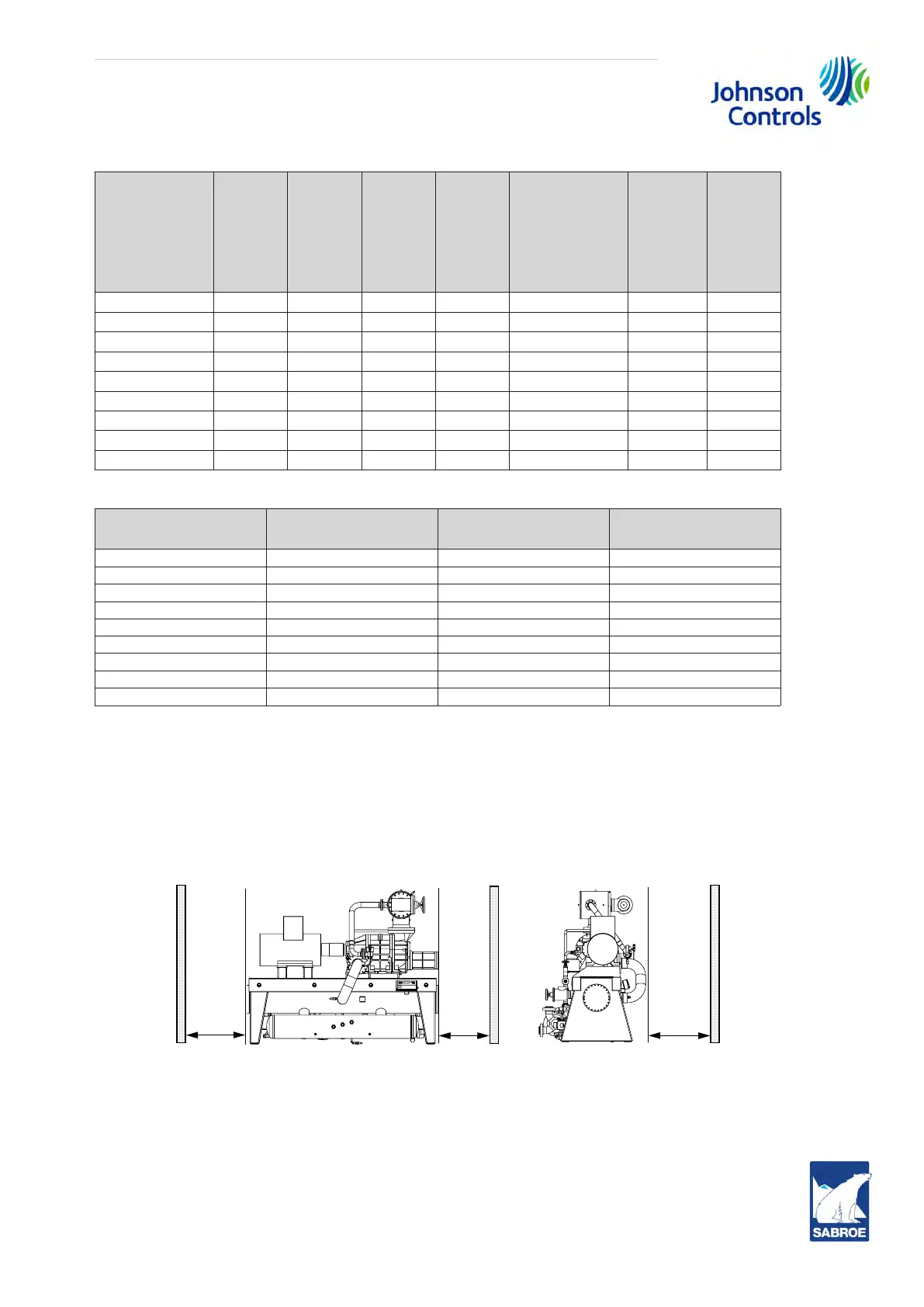

6.3 Planning the machine room

When planning the machine room, make sure that there is enough space around the plant to allow

easy access for repair and maintenance tasks.

See also complete dimensioned sketches of the individual compressor types and units.

Fig. 65: Planning the machine room

Loading...

Loading...