Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2020.10

139/168

Maintenance instructions

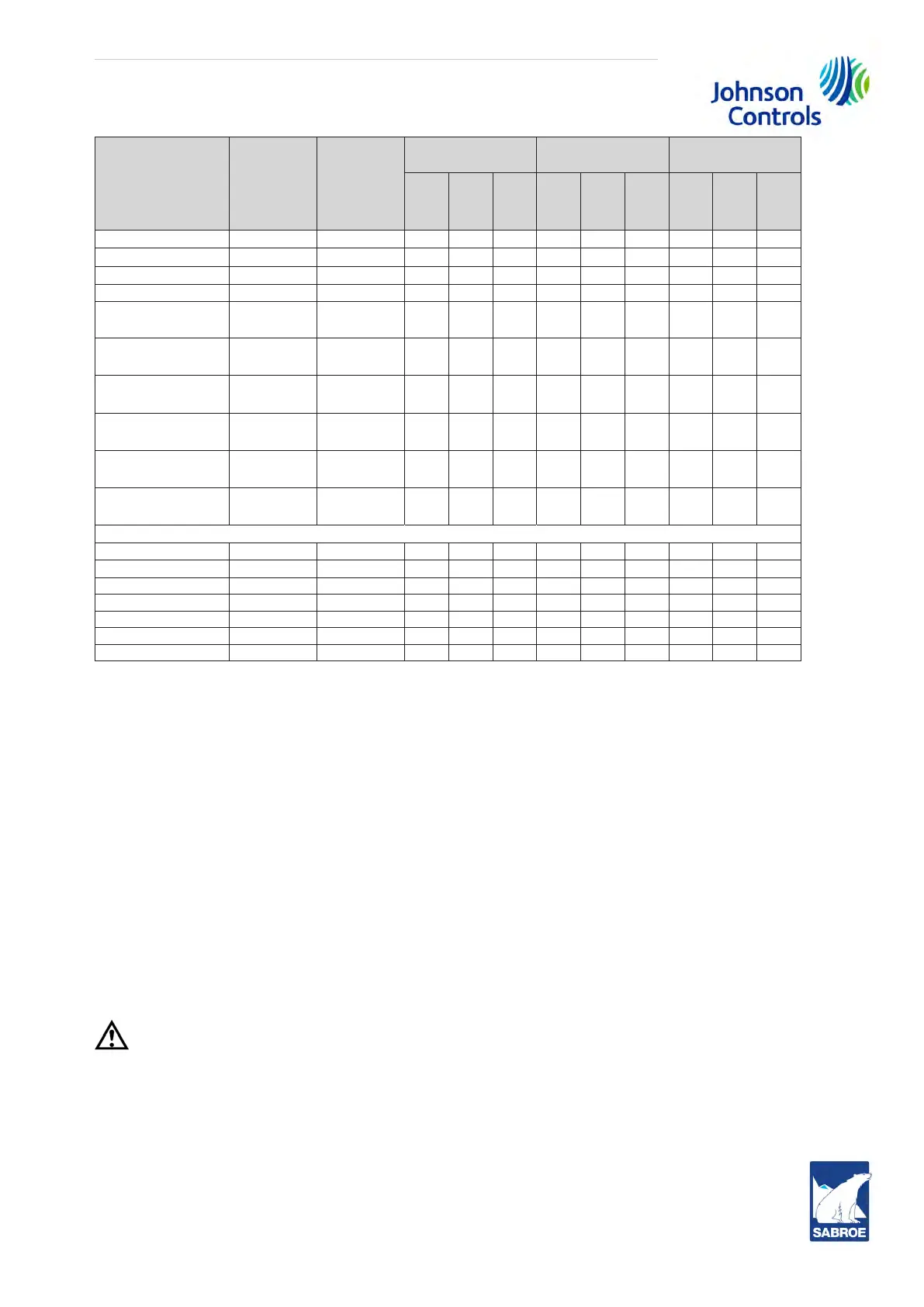

Parameter Unit Method

Sabroe oil

PAO 68

Sabroe oil

AP 68

Sabroe oil

A 100

Tar-

get

spec.

Max.

Min.

Tar-

get

spec.

Max.

Min.

Tar-

get

spec.

Max.

Min.

Viscosity @40°C cSt ASTM D 445 66 76 53 64 74 51 100 115 80

TAN*1) mg KOH/g ASTM D 664 0.03 0.2

-

0.01 0.02

-

0.05 0.02

-

SAN*2) mg KOH/g ASTM D 665

-

0

- -

0

- -

0

-

Water

ppm

Karl Fisher

-

100

- -

100

- -

100

-

Apperarance

- - re-

port

re-

port

re-

port

Colour

-

ASTM D

1500

re-

port

re-

port

re-

port

Pentane Insolubles

(Sum)

W% MM 490

-

0.05

-

0.05

- -

0.05

-

Oxidation abs/cm IR,1700-

1720/cm

-

5

- -

5

- -

5

-

Nitration

abs/cm IR,1627-

1637/cm

-

5

- -

5

- -

5

-

Nitro Compounds abs/cm

IR,1547-

1557/cm

-

0.5

- -

0.5

- -

0.5

-

Maximum values for metal content in the oil)

Lead

ppm

ICP

-

10

- -

10

- -

10

-

Copper

ppm

ICP

-

10

- -

10

- -

10

-

Silicium

ppm

ICP

-

25

- -

25

- -

25

-

Iron

ppm

ICP

-

100

- -

100

- -

100

-

Chromium

ppm

ICP

-

5

- -

5

- -

5

-

Aluminium

ppm

ICP

-

10

- -

10

- -

10

-

Tin

ppm

ICP

-

10

- -

10

- -

10

-

1) TAN (Total Acid Number) is only non-ammonia applications

2) SAN (Strong Acid Number) is only reported for non-ammonia applications

A report is compiled for every sample received. This report will describe:

• whether the oil can still be used without taking any further action.

• whether the oil can be used after it has been filtered through a very fine filter. If this is nec-

essary, the oil must be pumped directly from the compressor unit through a 3 micron filter

and back to the unit. The system must be completely closed to prevent the oil from being

affected by moisture in the air.

• whether the oil can no longer be used.

The report will always be sent to the address stated on the sample label included in the form set.

A copy will be sent to Johnson Controls Denmark so that we are in a position to advise you, if

required.

11.12 Charging compressor with lubricating oil

Caution!

Only charge oil when the unit pressure is below 6 bar!

Oil charging is carried out by means of a portable oil charging pump, see Fig. 86. Proceed as

follows:

1. Connect the high-pressure hose, pos. 7, to the service valve, pos. 106, on the unit via the

non-return valve, pos. 12. Use the correct reduction nipple. See Fig. 87.

2. Place the free end of the suction hose from the pump, pos. 1, together with the by-pass

hose, pos. 2, in the barrel.

Loading...

Loading...