Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2020.10

61/168

Technical description

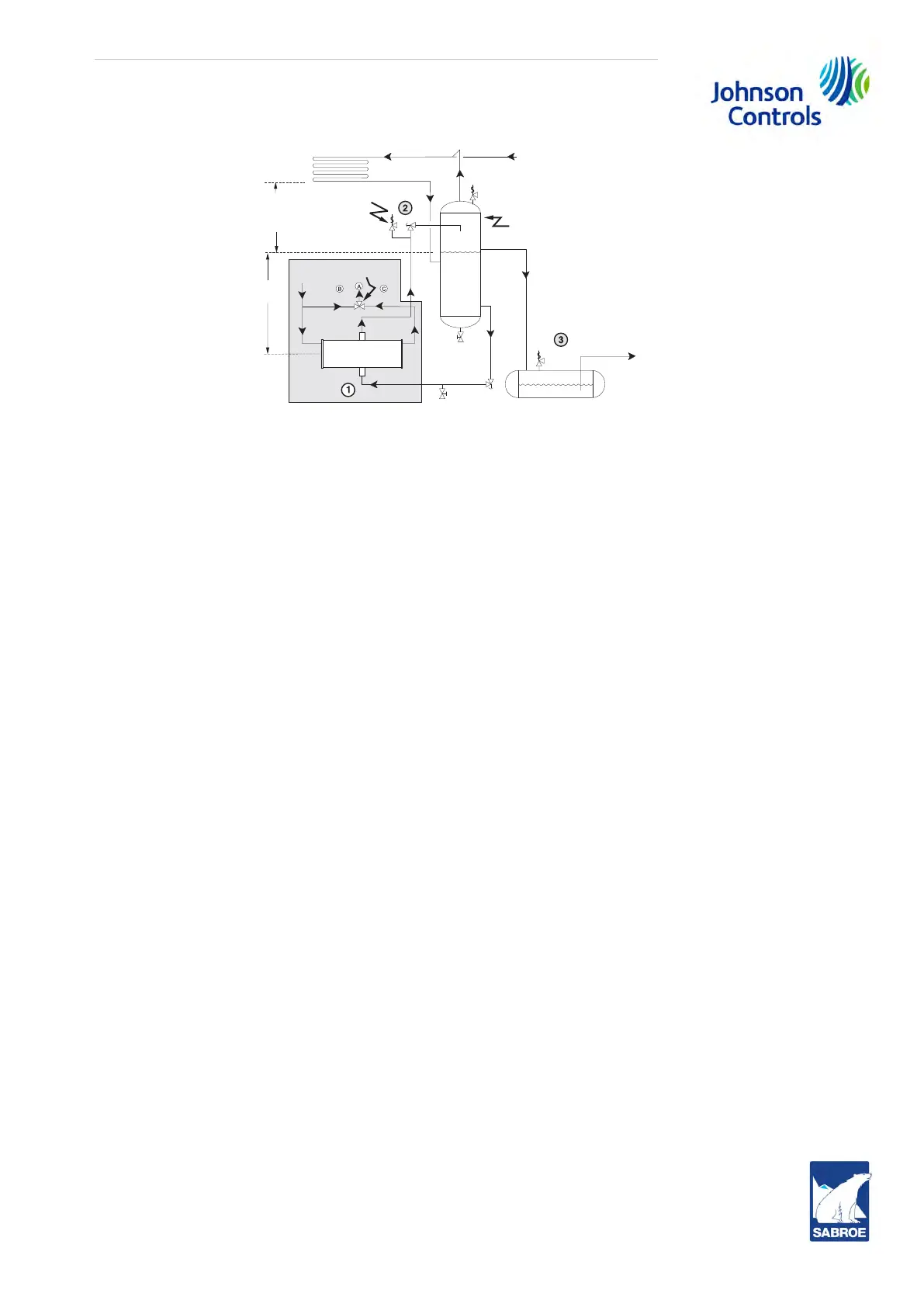

Fig. 37

1. The thermosyphon oil cooler is supplied with the oil side piped to the compressor unit and stub

ends supplied on the refrigerant side.

2. A refrigerant-side safety valve is required in this location only when refrigerant isolation valves

are installed between the cooler and thermosyphon receiver. If no valves are used between the

cooler and TSOC receiver, the safety valve on the TSOC receiver must be sized to handle the vol-

ume of both vessels. Then, the safety valve on the cooler vent (liquid refrigerant side) can be

eliminated.

3. The system receiver must be below the thermosyphon receiver in this arrangement.

4.30 Water-cooled oil cooling

The plate and shell or plate-and-shell type water-cooled oil cooler is mounted on the unit com-

plete with all oil piping. The customer must supply adequate water connections. Determine the

size of the water-cooled oil cooler supplied with the unit as outlined in COMP1. The water supply

must be sufficient to meet the required flow.

Johnson Controls Denmark recommends a closed-loop system for the waterside of the oil cooler.

Careful attention to water treatment is essential to ensure adequate life of the cooler if cooling

tower water is used. It is imperative that the condition of cooling water and closed-loop

fluids are analysed regularly and as necessary and maintained at a pH of 7.4, but not

less than 6.0 for proper heat exchanger life. After initial start-up of the compressor unit, the

strainer at the inlet of the oil cooler should be cleaned several times during the first 24 hours of

operation.

System condenser

Vapour

Safety

v

alve

Static head

t

o overcome

condenser

pressure drop

Thermosyphon

r

eceiver

Liquid overflow

dr

ain to receiver

To system

e

vaporator

System

receiver

(Mounted below

thermosyphon r

eceiver level)

Liquid

le

vel

Oil temp.

c

ontrol valve

Hot

Cool

Cool

oil out

Refrigerant in

Refrigerant

Hot oil in

Plate cooler

T

SOC

6 ft.

(183 cm)

M

in.

out

Loading...

Loading...