Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2020.10

147/168

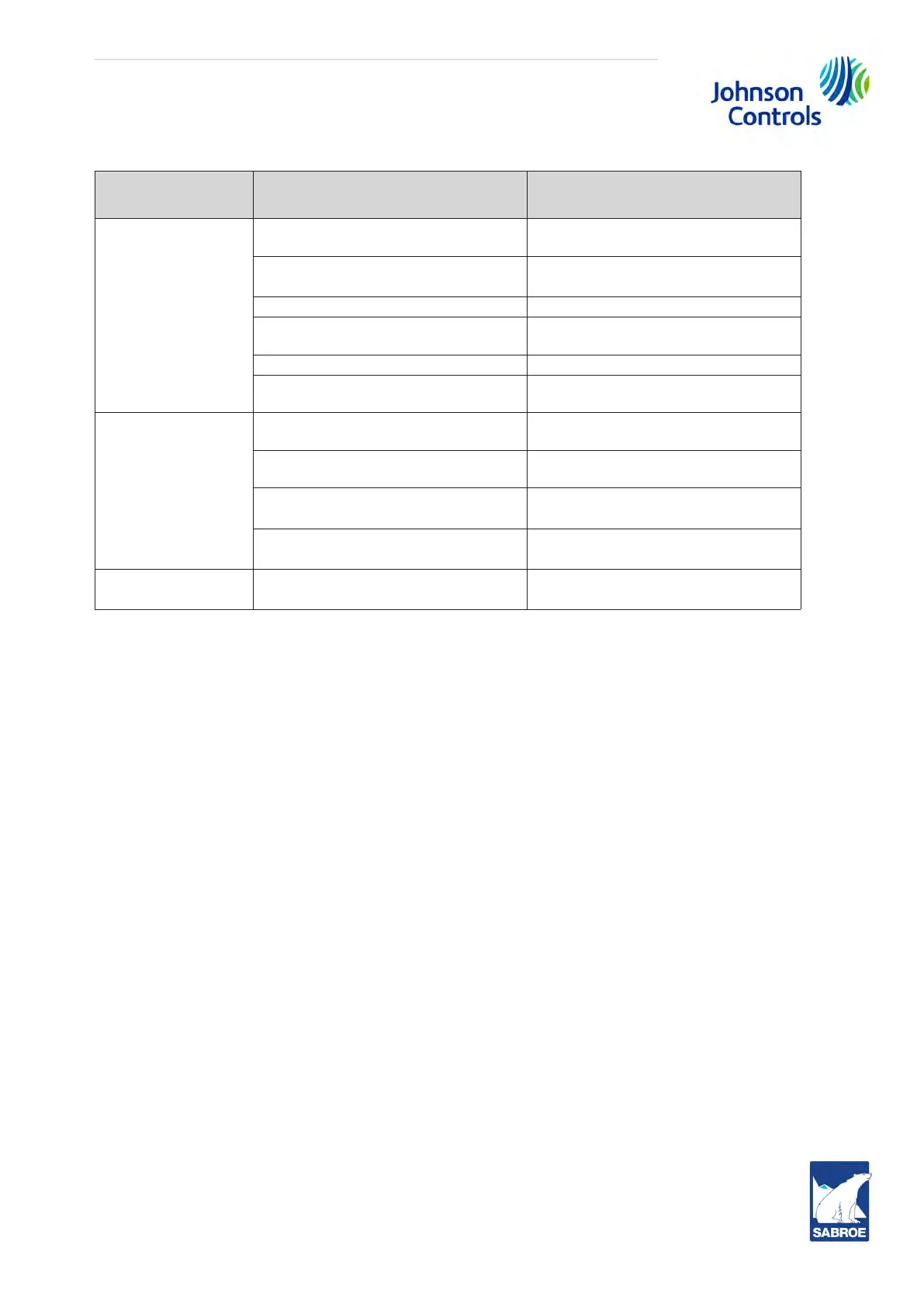

Faultfinding instructions

Compressor unit - oil separation

Symptom

Probable cause Solution

Gradual oil loss with

an oil level in the co-

alescer section sight

glass

Maintaining too high oil level.

Lower level by opening/adjusting

the oil return valve.

Refrigerant carry-over or liquid in-

jection overfeeding.

Correct operation.

Loss of suction superheat. Adjust evaporator feeds.

Contaminated oil, damaged or not

seated coalescer elements.

Replace oil charge and coalescers.

Coalescer return valve closed.

Open return valve.

Coalescing oil return line strainer

blocked.

Clean strainer.

Rapid loss with no oil

level in the coalescer

section sight glass

On shutdown, compressor unit suc-

tion check valve did not close.

Repair valve.

Suction check valve bypass open too

far.

Close valve.

Coalescers loose or not seated

properly.

Correct or replace.

On economised unit: economiser

check valve not working.

Repair or replace.

Shaft seal leakage

Leakage exceeds normal allowable

rate of 7 drops per minute.

Replace seal.

Table 55: Compressor unit - oil separation

Loading...

Loading...