Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

008831 en 2020.10

65/168

Technical description

subcooling is provided by flashing liquid in the economiser cooler to an intermediate pressure

level. The intermediate pressure is provided by a port located part way down the compression

process on the screw compressor. As the screw compressor unloads, the economiser port will

drop in pressure level, eventually being fully open to suction. Because of this, an output from the

microprocessor is generally used to turn off the supply of flashing liquid on a shell and coil or DX

economiser when the capacity falls below approximately 45%-60% capacity (85%-90% slide

valve position). This is done because the compressor will be more efficient operating at a higher

slide valve position with the economiser turned off, than it will at a low slide valve position with

the economiser turned on. Please note, however, that shell and coil and DX economisers can be

used at low compressor capacities in cases where efficiency is not as important as assuring that

the liquid supply is subcooled. In such cases, the economiser liquid solenoid can be left open

whenever the compressor is running.

Due to the tendency of the port pressure to fall with decreasing compressor capacity, a back-pres-

sure regulator valve (BPR) is generally required on a flash economiser system (Fig. 49) in order to

maintain some preset pressure difference between the subcooled liquid in the flash vessel and

the evaporators. If the back-pressure regulator valve is not used on a flash economiser, it is possi-

ble that no pressure difference will exist to drive liquid from the flash vessel to the evaporators,

since the flash vessel pressure will approach suction pressure at a decreased slide valve position.

In cases where wide swings in pressure are anticipated in the flash economiser vessel, it may be

necessary to add an outlet pressure regulator to the flash vessel outlet to avoid overpressure of

the economiser port, which could result in motor overload. Example: A system feeding liquid to

the flash vessel in batches.

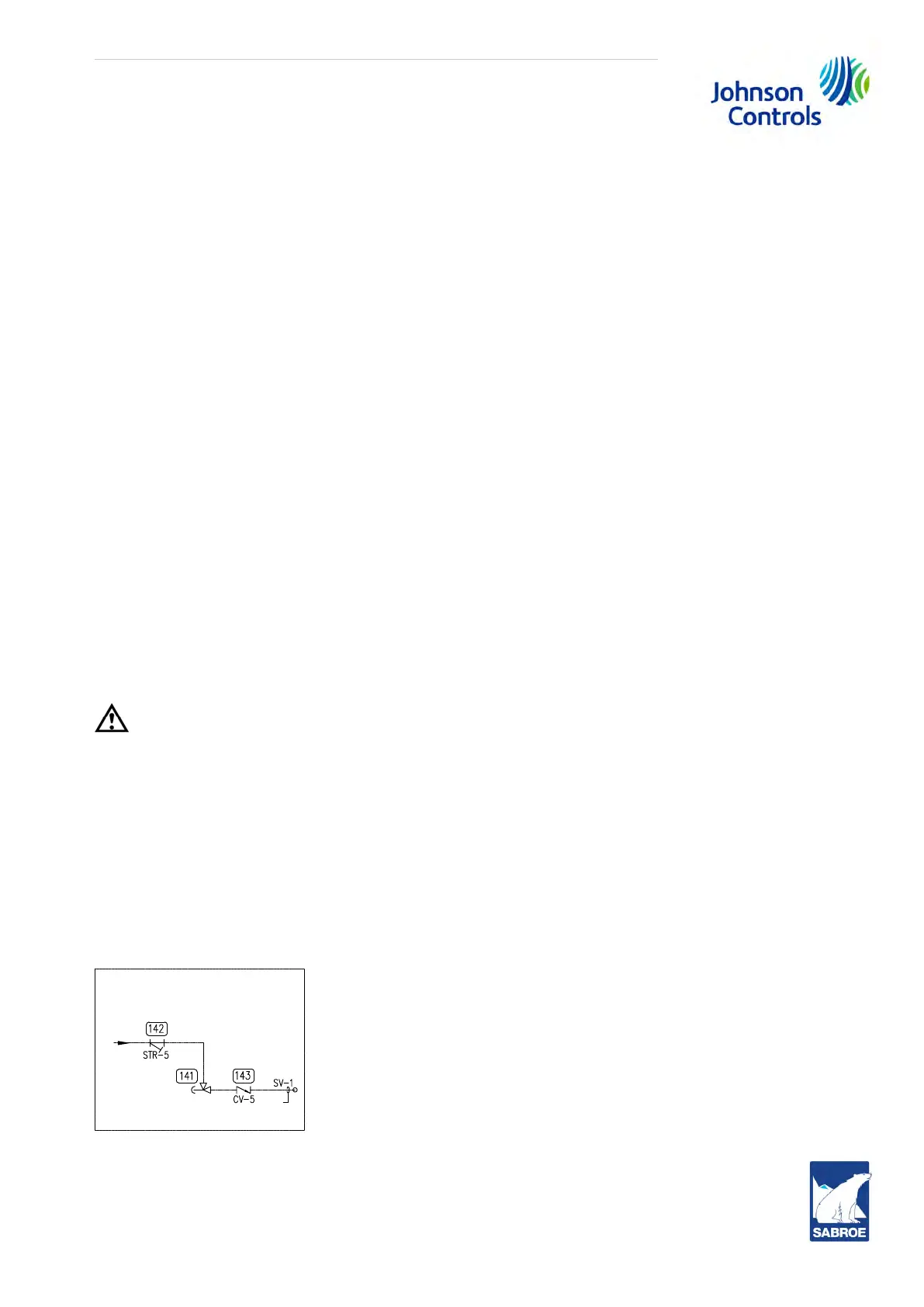

The recommended economiser systems are shown below. Notice that in all systems there should

be a strainer (STR) and a check valve (CV) between the economiser vessel and the economiser

port on the compressor. The strainer prevents dirt from passing into the compressor, and the

check valve prevents oil from flowing from the compressor unit to the economiser vessel during

shutdown.

Caution!

It is recommended to use piston-type check valves for installation in the economiser line, as op-

posed to disc-type check valves. The latter are more prone to gas pulsation-induced failure. The

isolation and check valves as well as the strainer should be located as closely as possible to the

compressor, preferably within 1 metre.

Anti-vibration kit

For SGC compressors running ammonia at high suction temperature and variable frequency drive

(VSD), an anti-vibration kit should be installed on the economiser line. The anti-vibration kit con-

sists of a strainer, a stop valve, a check valve and a damper (pos. 208). The damper should be in-

stalled as the last device before the compressor.

Fig. 44: Standard economiser kit

Loading...

Loading...