JOHNSON CONTROLS

18

FORM 160.75-N1

ISSUE DATE: 04/15/2019

SECTION 2 - INSTALLATION

bolts or coupling and checked for piping alignment. If

any of the bolts are bound in their holes, or if the con-

nection springs are out of alignment, the misalignment

must be corrected by properly supporting the piping or

by applying heat to anneal the pipe.

If the piping is annealed to relieve stress,

the inside of the pipe must be cleaned of

scale before it is nally bolted in place.

EVAPORATOR AND CONDENSER WATER

PIPING

The evaporator and condenser liquid heads of chiller

have nozzles which are grooved, suitable for welding

150 psig DWP flanges or the use of flexible couplings.

Factory mounted flanges are optional.

The nozzles and water pass arrangements are furnished in ac-

cordance with the job requirements (refer to Product Draw-

ings) furnished with the job. Standard units are designed for

150 psig DWP on the water side. If job requirements are for

greater than 150 psig DWP, check the unit data plate before

applying pressure to evaporator or condenser to determine if

the chiller has provisions for the required DWP.

Inlet and outlet connections are identified by labels

placed adjacent to each nozzle.

The coolant temperature inside any JCI-supplied liquid-

cooled motor starter must be maintained above the dewpoint

temperature in the equipment room to prevent condensing

water vapor inside the starter cabinet. Therefore, an addi-

tional temperature-controlled throttle valve is needed in the

flow path for the starter heat exchanger to regulate cooling

above the equipment room dewpoint for applications using

cooling sources other than evaporative air-exchange meth-

ods, such as wells, bodies of water, and chilled water. The

temperature control valve should be the type to open on in-

creasing drive coolant temperature, fail-closed, and set for a

temperature above dewpoint. It can be requested as factory-

supplied on a chiller order by special quotation.

Chilled Water

Foreign objects which could lodge in, or block flow

through, the evaporator and condenser tubes must be

kept out of the water circuit. All water piping must be

cleaned or flushed before being connected to the chiller

pumps, or other equipment.

Permanent strainers (supplied by others) are required

in both the evaporator and condenser water circuits to

protect the chiller as well as the pumps, tower spray

nozzles, chilled water coils and controls, etc. The

strainer must be installed in the entering chilled water

line, directly upstream of the chiller.

Water piping circuits should be arranged so that the

pumps discharge through the chiller, and should be

controlled as necessary to maintain essentially constant

chilled and condenser water flows through the unit at

all load conditions.

If pumps discharge through the chiller, the strainer

may be located upstream from pumps to protect both

pump and chiller. (Piping between strainer, pump and

chiller must be very carefully cleaned before start-up.)

If pumps are remotely installed from chiller, strainers

should be located directly upstream of the chiller.

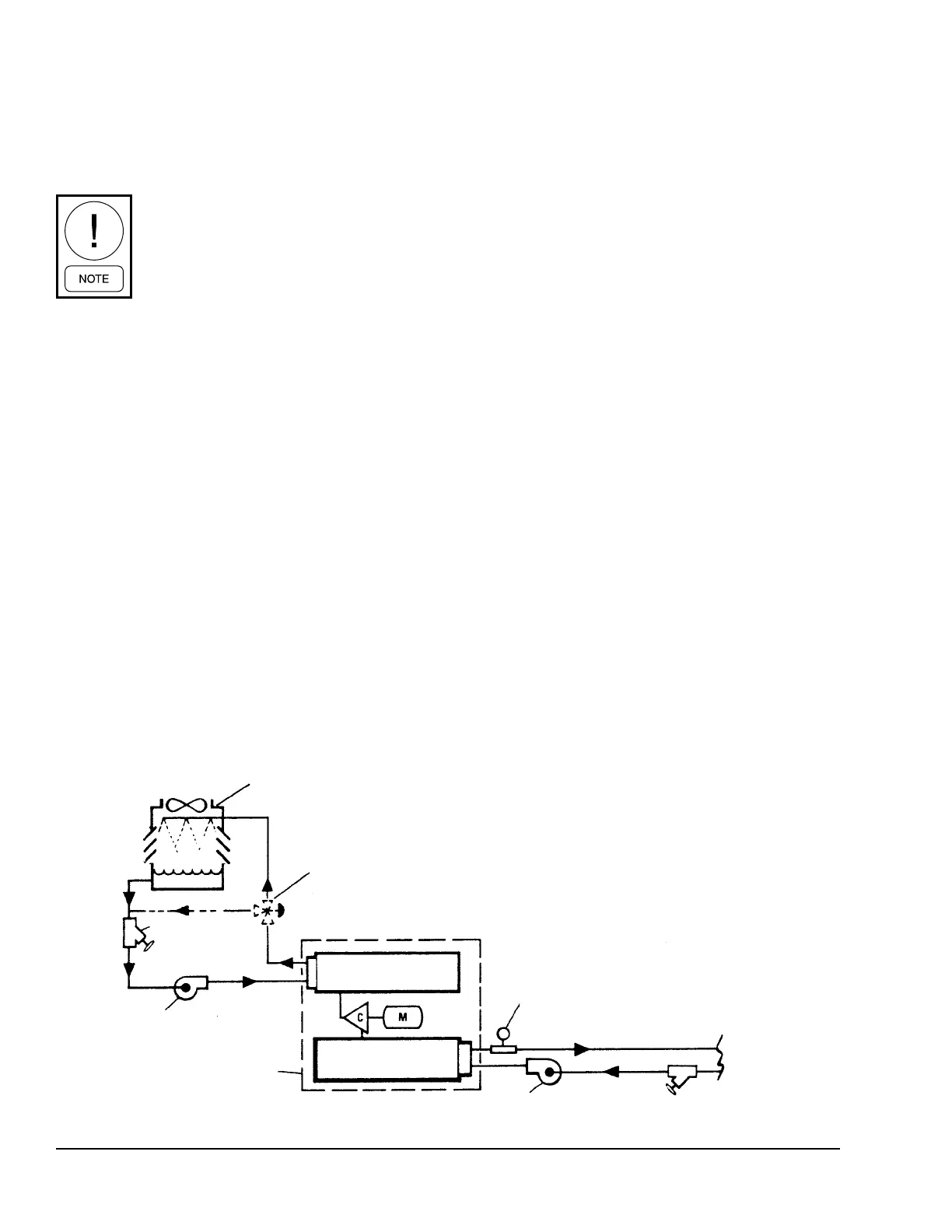

FIGURE 8 - SCHEMATIC OF A TYPICAL PIPING ARRANGEMENT

LD08529

EVAPORATOR

CONDENSER

STRAINER

STRAINER

COOLING

TOWER

COOLING

UNIT

C = COMPRESSOR

M = MOTOR

FLOW SWITCH

CHILLED WATER PUMP

COOLING TOWER

PUMP

COOLING UNIT

CODEPAK

CONTROLLED COOLING

TOWER BYPASS VALVE

(IF NECESSARY)

Loading...

Loading...