JOHNSON CONTROLS

21

SECTION 2 - INSTALLATION

FORM 160.75-N1

ISSUE DATE: 04/15/2019

2

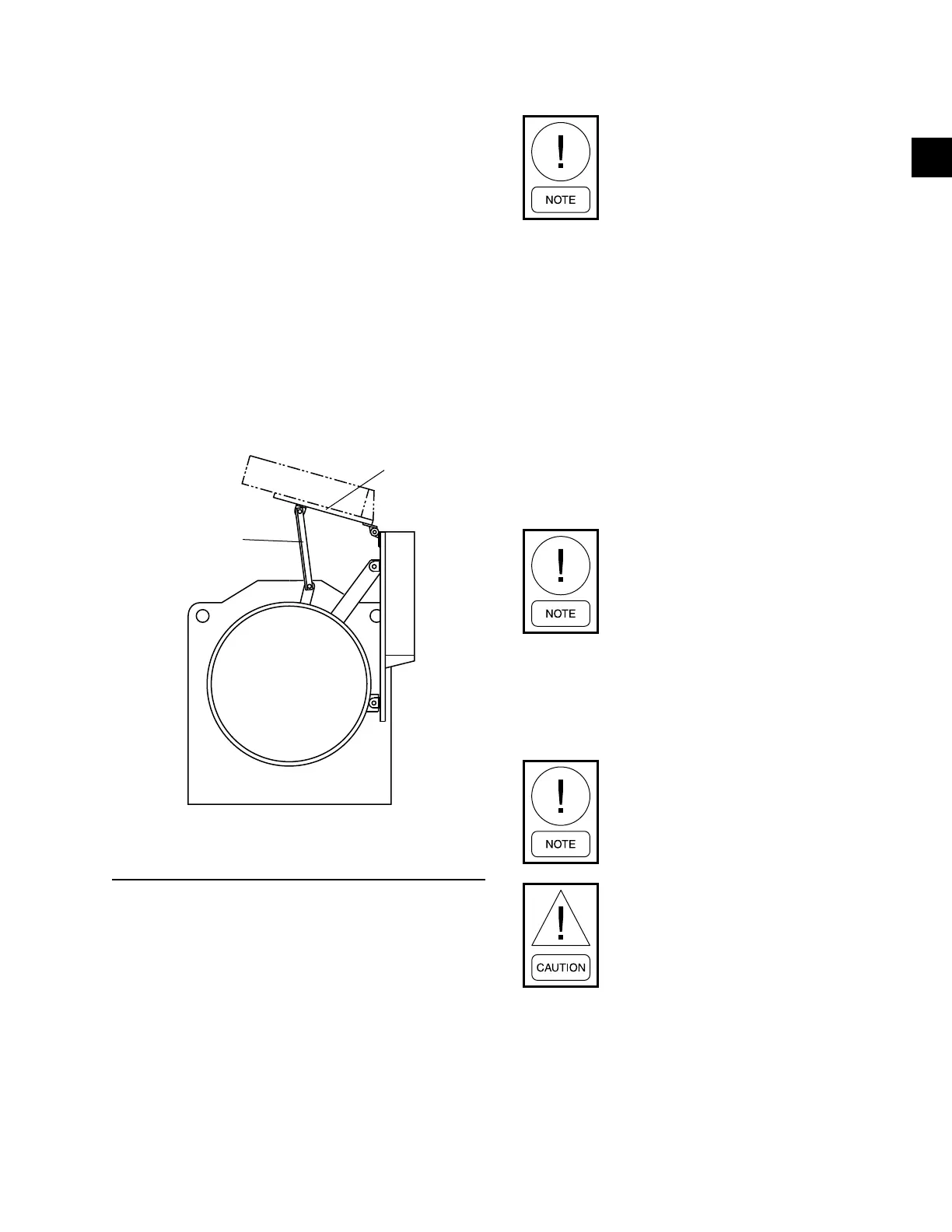

CONTROL PANEL POSITIONING

On large YK chillers equipped with H9 and K1-K7

compressors, the control panel height can be adjusted.

Chillers equipped with P and Q compressors the

control panel height is NOT adjustable. The OptiV-

iew™ Control Center is placed in a position above the

evaporator for shipping. To move the control center

into position for operation, proceed as follows:

1. While supporting the control center, remove the

hardware between the support arms and the evap-

orator.

2. Swing the control center into a vertical position.

3. Slide the control center down the guide rails to the

proper position. Tighten securely.

4. Discard unused hardware.

FIGURE 10 - CONTROL PANEL POSITIONING

(H9, K1-K7)

LD03826

CONTROL WIRING

On units shipped disassembled, after installation of the

control center, control wiring must be completed be-

tween unit components and control center, solid state

starter, or variable speed drive, when used, using wir-

ing harnesses furnished. Refer to Installation and Re-

assembly - Unit (Form 160.75-N3).

Field wiring connections for commonly encountered

control modifications (by others) if required, are

shown on Wiring Diagrams – Field Control Modifica-

tions (Form 160.75-PW4).

No deviations in unit wiring from that

shown on drawings furnished shall be

made without prior approval of the John-

son Controls representative.

POWER WIRING

Chiller with Electromechanical Starter

A 115 volt – single phase – 60 or 50 Hertz power sup-

ply of 20 amperes must be furnished to the control

center, from the control transformer (2 KVA required)

included with the compressor motor starter. Do NOT

make final power connections to control center until

approved by YORK representative.

OIL PUMP – 3 PHASE STARTER

Separate wiring or a fused disconnect switch should be

supplied by the installer.

Remote Electromechanical starters for

the chiller must be furnished in accor-

dance with YORK Starter Specications

Product Drawing Form 160.73-PA1 to

provide the features necessary for the

starter to function properly with the

YORK control system.

Each chiller unit is furnished for a specific electrical

power supply as stamped on the Unit Data Plate, which

also details the motor connection diagrams.

To insure proper motor rotation the starter

power input and starter to motor con-

nections must be checked with a phase

sequence indicator in the presence of the

Johnson Controls representative.

DO NOT cut wires to nal length or make

nal connections to motor terminals or

starter power input terminals until ap-

proved by the Johnson Controls repre-

sentative.

YK Motors (Electromechanical Starter)

Motor leads are furnished with a crimp type connection

having a clearance hole for a 3/8" bolt, motor terminal

lugs are not furnished. Refer to Wiring Labels in mo-

tor terminal box for hook-up to suit motor voltage and

amperage for power wiring connections.

Loading...

Loading...