JOHNSON CONTROLS

9

SECTION 1 - INTRODUCTION

FORM 160.75-N1

ISSUE DATE: 04/15/2019

1

INSPECTION – DAMAGE – SHORTAGE

The unit shipment should be checked on arrival to see

that all major pieces, boxes and crates are received.

Each unit should be checked on the trailer or rail car

when received, before unloading, for any visible signs

of damage. Any damage or signs of possible damage

must be reported to the transportation company imme-

diately for their inspection. Johnson Controls will not

be responsible for any damage in shipment, at job site,

or loss of parts. (Refer to Shipping Damage Claims,

Form 50.15-NM.)

When received at the job site all containers should be

opened and contents checked against the packing list.

Any material shortage should be reported to Johnson

Controls immediately. (Refer to Shipping Damage

Claims, Form 50.15-NM.)

CHILLER DATA PLATE

A unit data plate is mounted on the control center as-

sembly of each unit, giving unit model number; design

working pressure; water passes; refrigerant charge; se-

rial numbers; and motor power characteristics and con-

nection diagrams.

Additional information may be found on the motor data

plate. This information should be included when con-

tacting the factory on any problem relating to the motor.

LONG-TERM STORAGE

To protect the waterbox of pressure vessels from rust-

ing, the tube side (water side) has been purged and

charged with nitrogen to a positive pressure of 5 psig

to 7 psig.

Do not break the seal or remove closures until ready

for set up. Relieve pressure as per the following proce-

dure (see Figure 3 on page 10).

Failure to follow the following procedures

will cause severe personal injury or death

to operators themselves or people on-site.

It is the obligation and responsibility of

operators to identify and recognize the

inherent hazards of material under pres-

sure and to protect themselves.

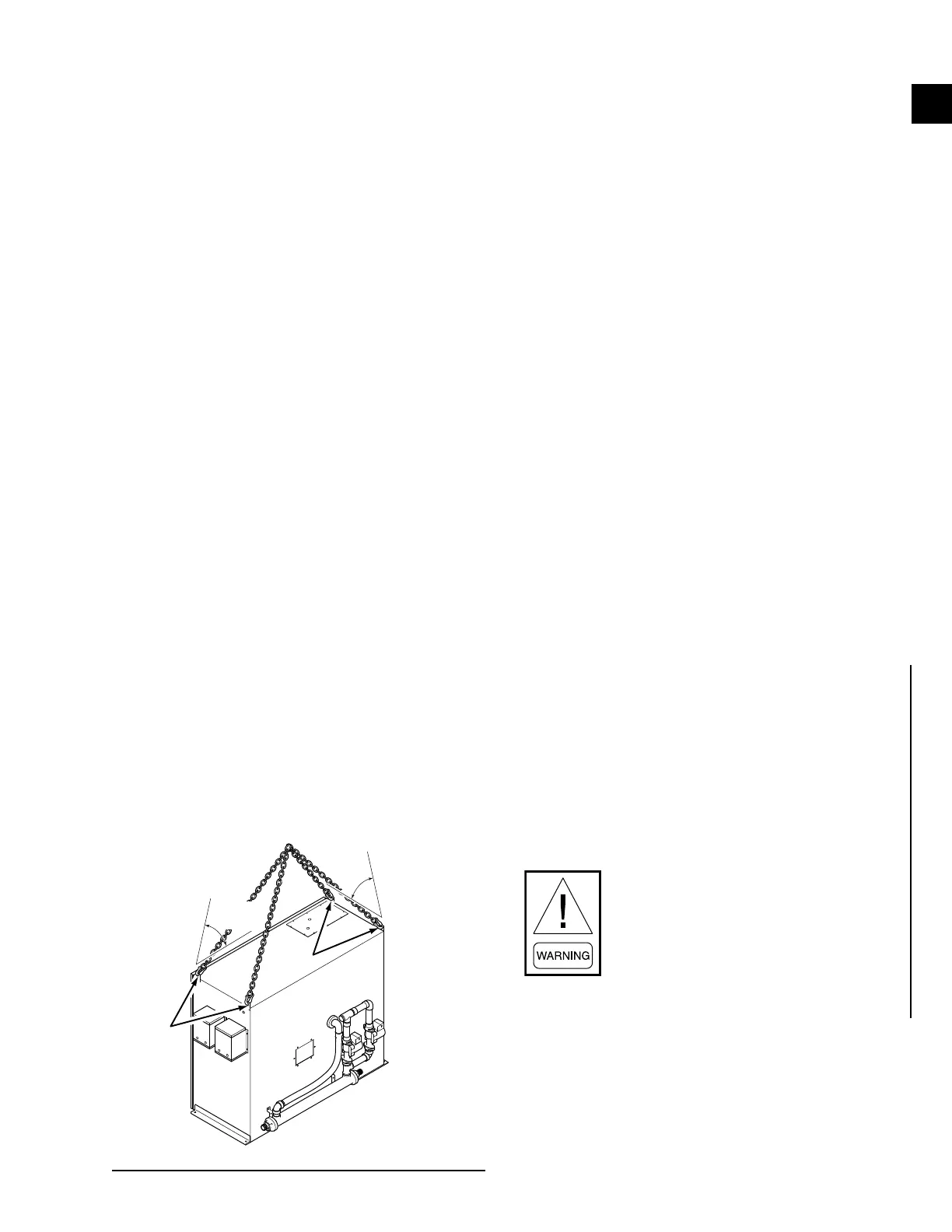

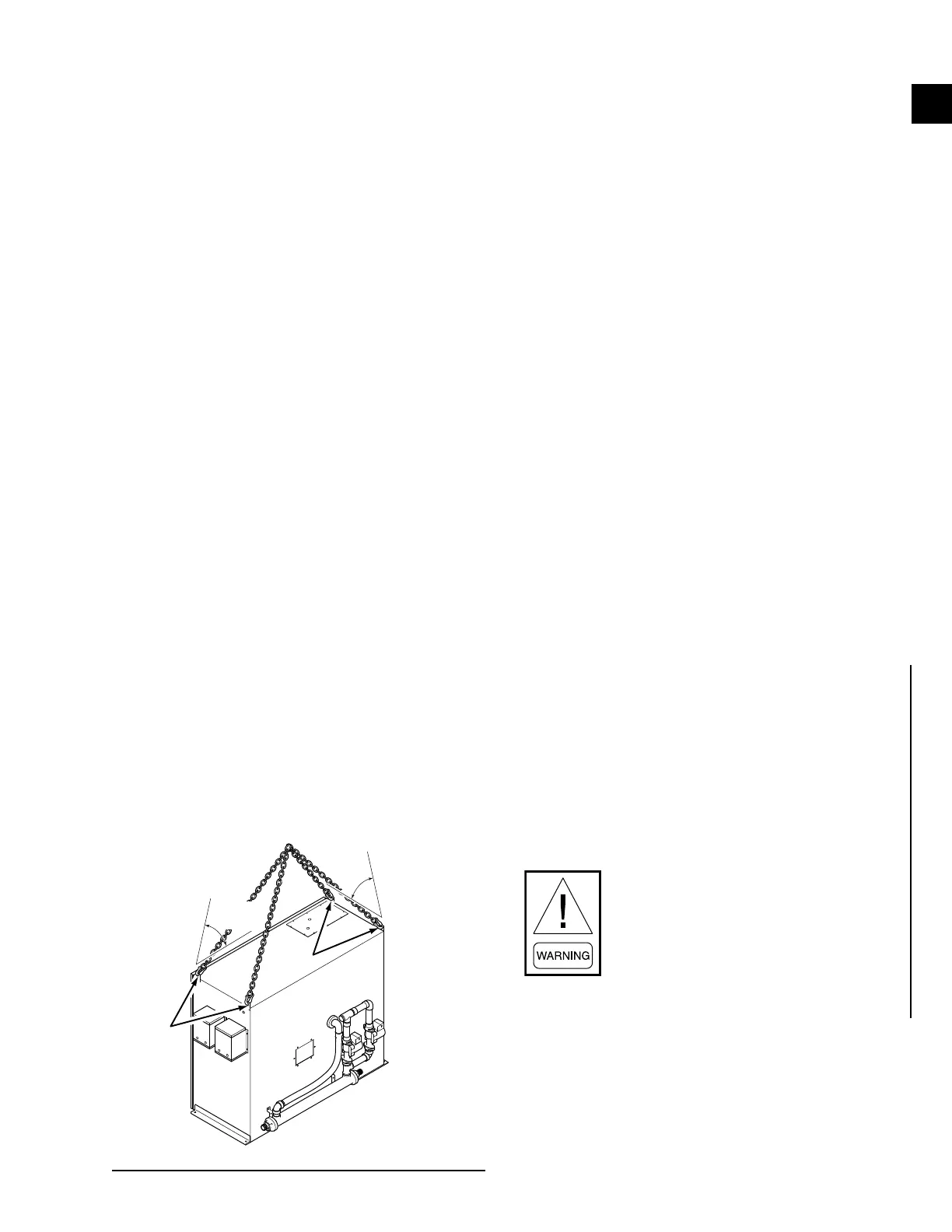

FORM 9 – Unit Separate from Variable Speed

Drive

Shipped as two major assemblies:

• Chiller Unit

• Variable Speed Drive

The unit is first factory assembled, refrigerant piped,

wired and leak tested; then dismantled for shipment.

Evaporator/condenser is not skidded.

All wiring integral with compressor is left on it, and

all conduit is left on shell. All openings on compressor,

and shell are closed and charged with dry nitrogen (2

to 3 PSIG).

Miscellaneous packaging of tubing, water temperature

controls, wiring, isolators, etc. The unit is shipped with

a nitrogen charge. Refrigerant charge shipped in ap-

propriate cylinders. See Figure 2.

FORM 10 – Unit Separate from Variable Speed

Drive

Shipped as two major assemblies:

• Chiller Unit

• Variable Speed Drive

The unit is first factory assembled, refrigerant piped,

wired and leak tested; then dismantled for shipment.

Evaporator/condenser is not skidded.

All wiring integral with compressor is left on it, and all

conduit is left on shell.

Miscellaneous packaging of tubing, water temperature

controls, wiring, isolators, etc. The unit is shipped with

refrigerant charge. See Figure 2.

Lifting

Holes

Lifting

Holes

65°

Min.

65°

Min.

FIGURE 2 - VARIABLE SPEED DRIVE RIGGING

Loading...

Loading...