JOHNSON CONTROLS

22

FORM 160.75-N1

ISSUE DATE: 04/15/2019

SECTION 2 - INSTALLATION

Chiller with Solid State Starter or Variable

Speed Drive

A chiller equipped with a factory mounted Solid State

Starter or Variable Speed Drive does not require wir-

ing to the compressor motor. The motor power wiring

is factory connected to the Solid State Starter or Vari-

able Speed Drive. Refer to Field Wiring Diagram. All

wiring to the control panel and the oil pump starter is

completed by the factory. A control transformer is fur-

nished with the Solid State Starter or Variable Speed

Drive.

Copper Conductors – Only copper conduc-

tors should be connected to compressor

motors and starters. Aluminum conductors

have proven to be unsatisfactory when

connected to copper lugs. Aluminum oxide

and the difference in thermal conductivity

between copper and aluminum cannot

guarantee the required tight connection

over a long period of time.

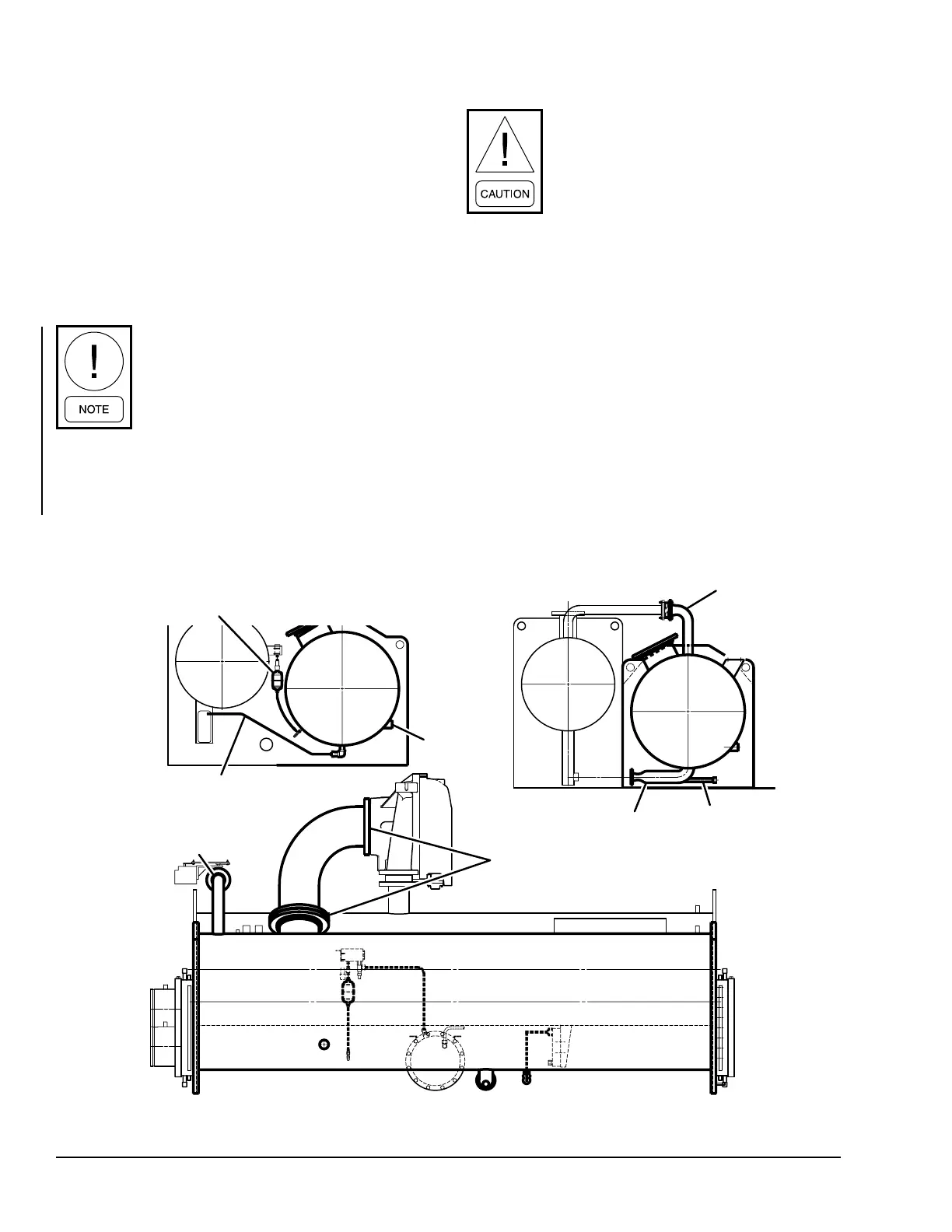

INSULATION

DO NOT eld insulate until the unit has

been leak tested under the supervision of

the Johnson Controls representative.

Insulation of the type specified for the job, or mini-

mum thickness to prevent sweating of 30°F (-1°C)

surfaces should be furnished (by others) and applied

to the evaporator shell, end sheets, liquid feed line to

flow chamber, compressor suction connection, and

evaporator liquid heads and connections. The liquid

head flange insulation must be removable, to allow

head removal for the tube maintenance. Details of ar-

eas to be insulated are given on the Product Drawing.

Units are furnished factory anti-sweat insulated on or-

der at additional cost. This includes all low tempera-

ture surfaces except the two (2) cooler liquid heads.

FIGURE 11 - UNIT INSULATION

LD12649

Input Drain

and

Charging

Connection

Liquid Line

NOTE: Bold lines represent Insulation

2” Liquid

Level Indicator

to Filter Drier

Refigerant from

Oil Cooler to Cooler

Hot Gas

Connection

Tape Insulation

around flanges to

allow for removal

CONDENSER

CONDENSER

EVAPORATOR

EVAPORATOR

Loading...

Loading...