– 118 –

Adjustment Procedure

Results of Improper Adjustment

(Important) No lubrication is needed for the thread take-up lever.

(Maintenance-free mechanism)

When adjusting the thread take-up lever mechanism, the following

items shall be observed:

[Replacement of thread take-up lever]

1. Remove the needle bar ❶ and the needle bar connector ❷.

2. Draw out the needle bar upper bushing ❸.

(Caution) Be careful not to hurt the needle bar upper bushing ❸

.

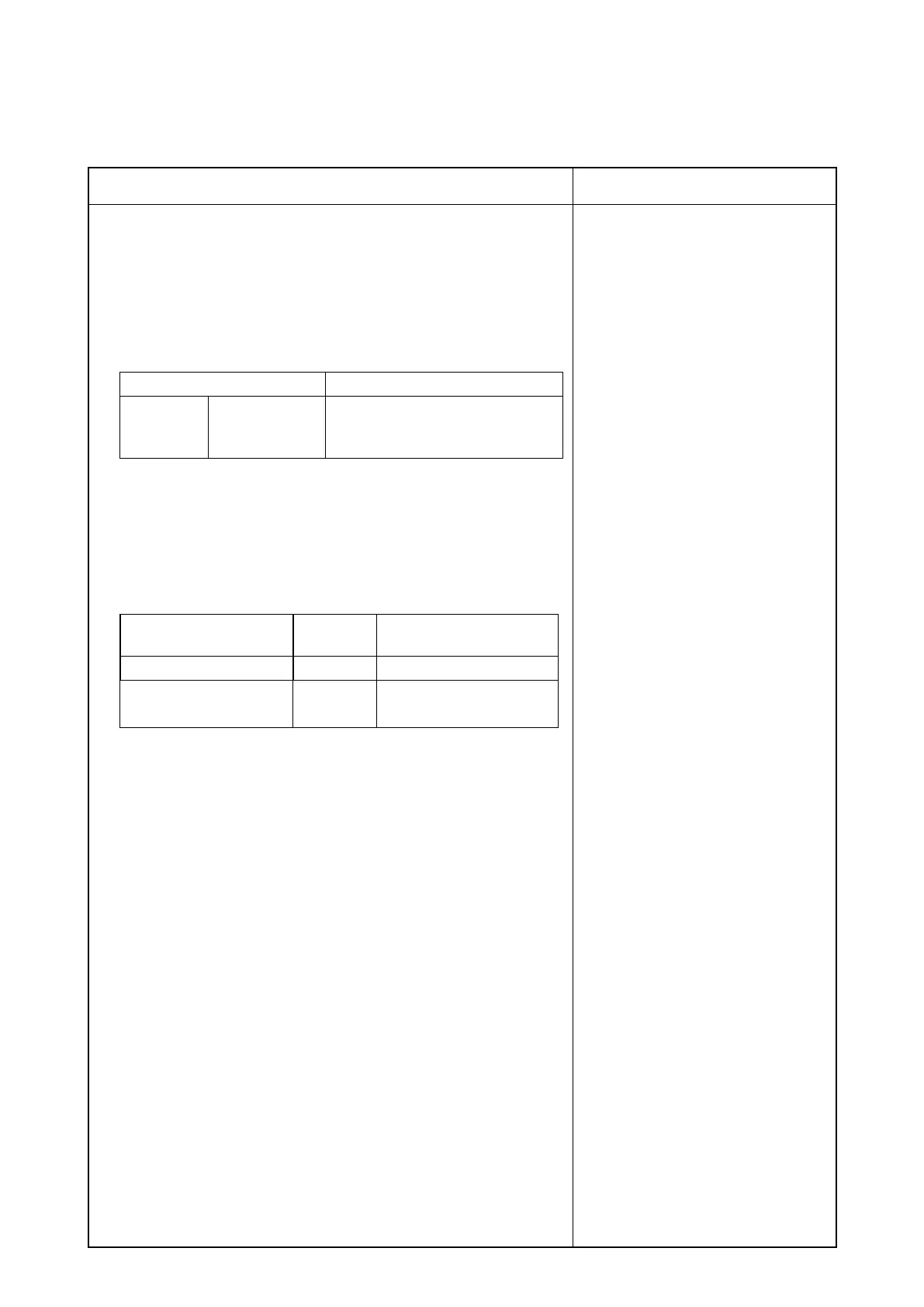

Needle bar upper bushing

❸

Remarks

Part No. 23608003

It is positioned at a concave

0.5mm from the upper surface of

an arm.

3. Loosen two needle bar crank setscrews ❺ of the main shaft coun-

terbalance ❹.

4. Loosen two thread take-up lever crank shaft setscrews ❼.

(The thread take-up lever support shaft ❻ is processed at.)

5. Loosen the thrust collar setscrew ❾ of the thread take-up lever

crank.

6. Pull out the crank shaft set toward you, except the thrust collar.

7. Remove the thread take-up lever (coupling) ❽.

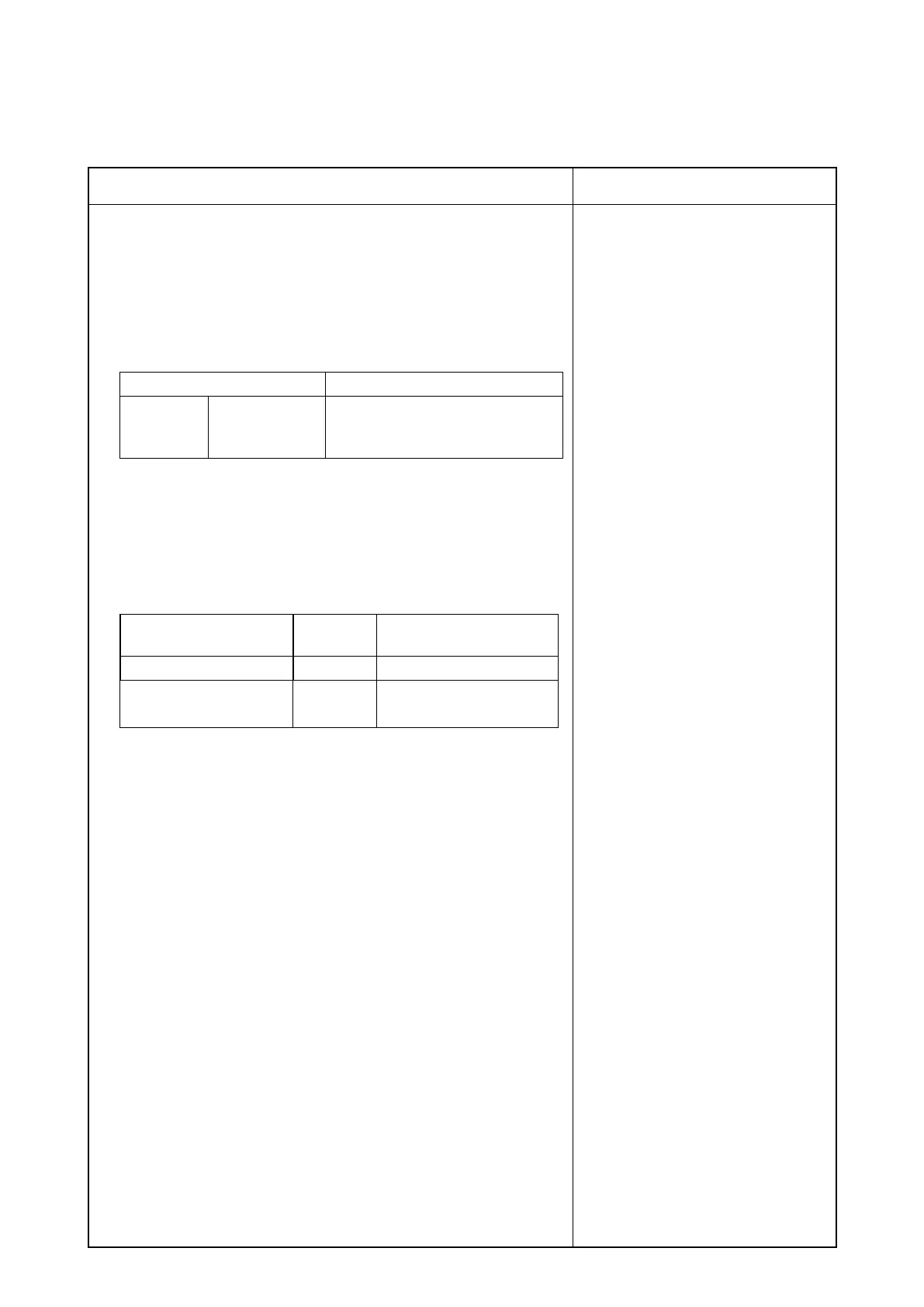

Thread take-up lever

(coupling)

❽

Part No.

Thread take-up lever stroke

Standard specication 40174341 110mm

Specication for heavy-

weight materials

40191118 108mm

8. Reassembly can be carried out in the reverse order for disassembly.

At that time, however, the items specied below shall be strictly

observed.

9. Insert the thread take-up lever unit to the position where it comes

in contact with the main shaft counterbalance ❹. Install the crank

shaft set in the order of the thread take-up lever crank, the thrust

collar, and the arm.

10. Fix the needle bar crank setscrew ❺.

(Caution) The rst screw in the revolving direction shall be made

to coincide with the at section of the shaft.

11. Remove thrust rattles from the thread take-up lever crank shaft ❻

and x it being pinched by the thrust collar and the E ring.

(Make thrust adjustments so that there are no thrust rattles and

the thread take-up lever crank can slide smoothly.)

12. Drive the needle bar upper bushing ❸ to install the parts of needle

bar ❶ and needle bar connector ❷.

13. Turn the hand wheel by hand several turns in forward direction and x

the thread take-up lever crank shaft ❻ by means of the thread take-up

lever crank shaft setscrew ❼, keeping adequate needle bar centering.

(Cautions)1. Improper centering of the needle bar ❶ causes the

thread take-up lever mechanism to be loaded inad-

equately, thus greatly affecting the durability.

2. Coincidence is absolutely needed between the at

section of the thread take-up lever crank shaft ❻

and the screw.

3. After conrming that there is no thrust backlash,

assemble the take-up lever thrust collar.

○

If this section is hurt, this will be a

cause of seizure.

○

If there is thrust backlash, this will

be a cause of breakage of the

thread take-up lever.

Loading...

Loading...