– 44 –

Adjustment Procedure

Results of Improper Adjustment

4) Response to problems occurring at the beginning

of sewing

○ Inthecaseneedlethreadbreakageoccurswhenusingathin

thread or fragile thread

○

Inthecaseneedlethreadisnottuckedonthewrongsideofma-

terial

○ Inthecaseneedlethreadbreakageoccurswhenstartingsewing

from the material end (such as sewing the material with needle

thread tucked on the undersurface of material)

Ifanyoftheaforementionedproblemsoccurs,theassistfunction

which works to reduce the presser foot pressure at the beginning of

sewing can be set by using the auto-lifter device ❹.

When P161 is set to "1", the assist function is activated.

○

Iftheautomaticpresserlifter

❹

is not used, set the presser foot

pressure to a lower level to make

it easier for the thread between

the presser and material to be

sewed to come out. (The recom-

mended presser foot pressure is

30 N (3 kg) or less.)

Adjust the presser foot pressure

and the sewing speed appro-

priatelytopreventinsufcient

feedefciencyduetojumpingor

other faults of the presser foot.

Conrmtheadjustmentresultby

actually sewing the material.

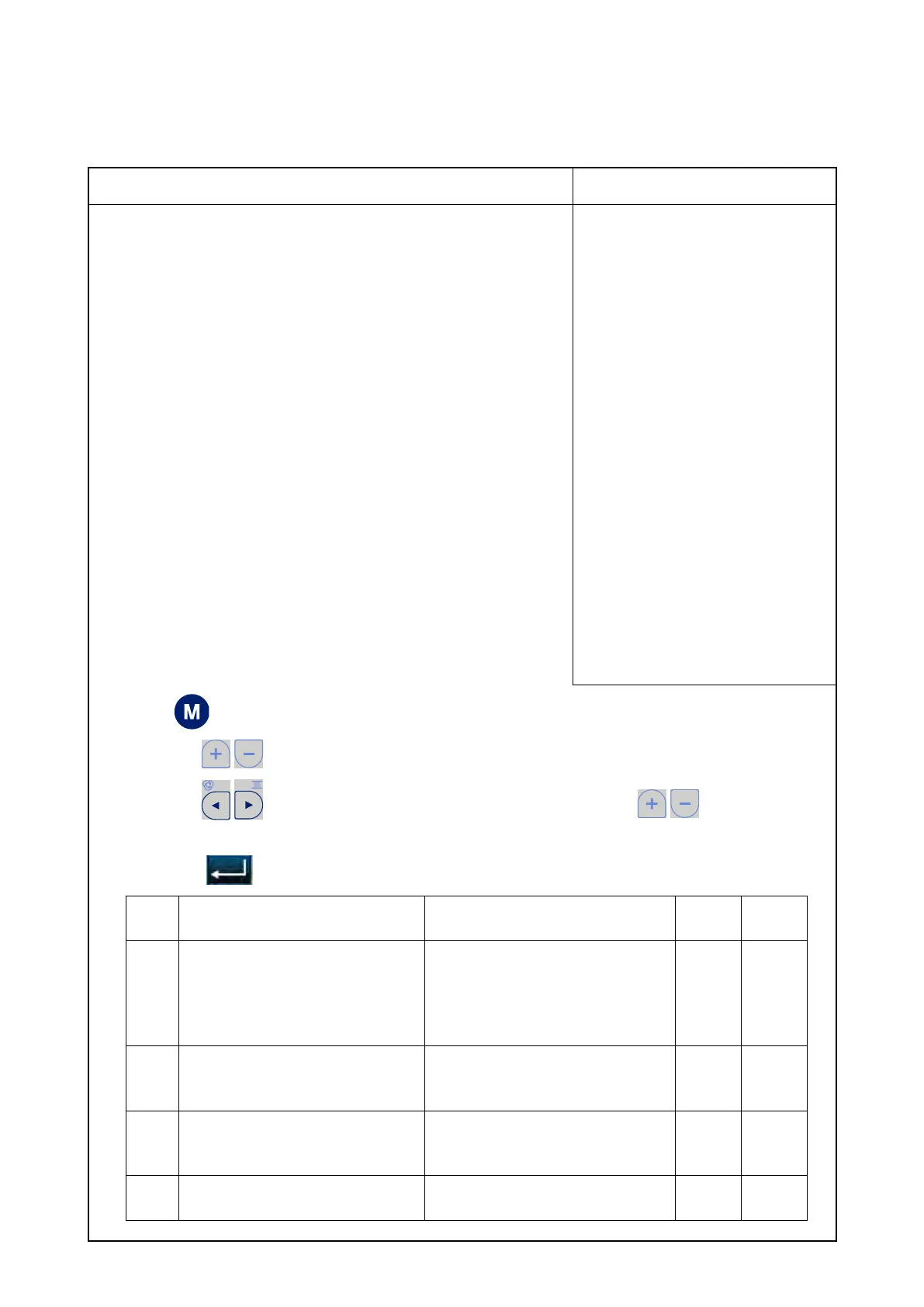

1. Press .

2. Press the

switch to select the item number in the table.

3. Press the

switch to activate the setting section, and press the switch to adjust

the value.

4.

Press the

switch to determine your selection.

No. Items Description Range

Initial

value

P161

Presser lifting operation at

holding thread ON/ OFF

Selects ON or OFF of the presser

lifting operation when the thread is

held.

1 : Lifting operation activated

0 : Lifting operation deactivated

0 to 1 0

P162

Angle at start of presser lifting

operation starts when the thread

is held

Sets the angle at the start of the

presser lifting operation when the

thread is held.

0 to 359 100

P164

Setting of presser lifting amount

at holding thread

Sets the amount of the presser

lifting movement when the thread

is held.

0 to 500 340

P165

Presser lifting operation time

when the thread is held

Sets the presser lifting operation

time when the thread is held.

1 to 990 20

Loading...

Loading...