– 3 –

List 3

List 2

Model

Scale of DOWN position detecting plate

LU-2200N series A

DU-141H-7, DSC series, DSU series, LZH-1290-7 D

Model

Handwheel

Upper-position

marker dot

Lower-position

maker dot

Reverse-rotation

needle-up position

marker dot

DU-141H-7, DSC series, DSU series Red White -

LZH-1290-7 Between red and red White -

LU-2200N series Between F and E K B

3)Checkrstthatthesewing-machineconnectorshavebeenremoved.Then,placethesewingmachine

controller in the setting where the sewing machine stops with its needle down. Loosen setscrew

of

synchronizer

. To adjust so that the sewing machine stops with its needle down, turn the joint to align

engraved marker dot

on the handwheel which represents the lower position (i.e., the sewing machine

stops with its needle down) with engraved marker dot

on the machine arm.

The location of the engraved marker dots on the handwheel which represents the stop position of the

sewing machine differs with model. Refer to List 3 for the location of the marker dots of your sewing ma-

chine.

4) After adjusting DOWN stop, set the sewing machine controller to the needle UP position setting and con-

rmtheUPstopposition.WhenUPstoppositionisimproper,performneadjustmentwithUPposition

detecting plate

.

5) After adjusting the stop position, attach the cover of synchronizer

. Return the sewing machine control-

ler to the needle DOWN position setting.

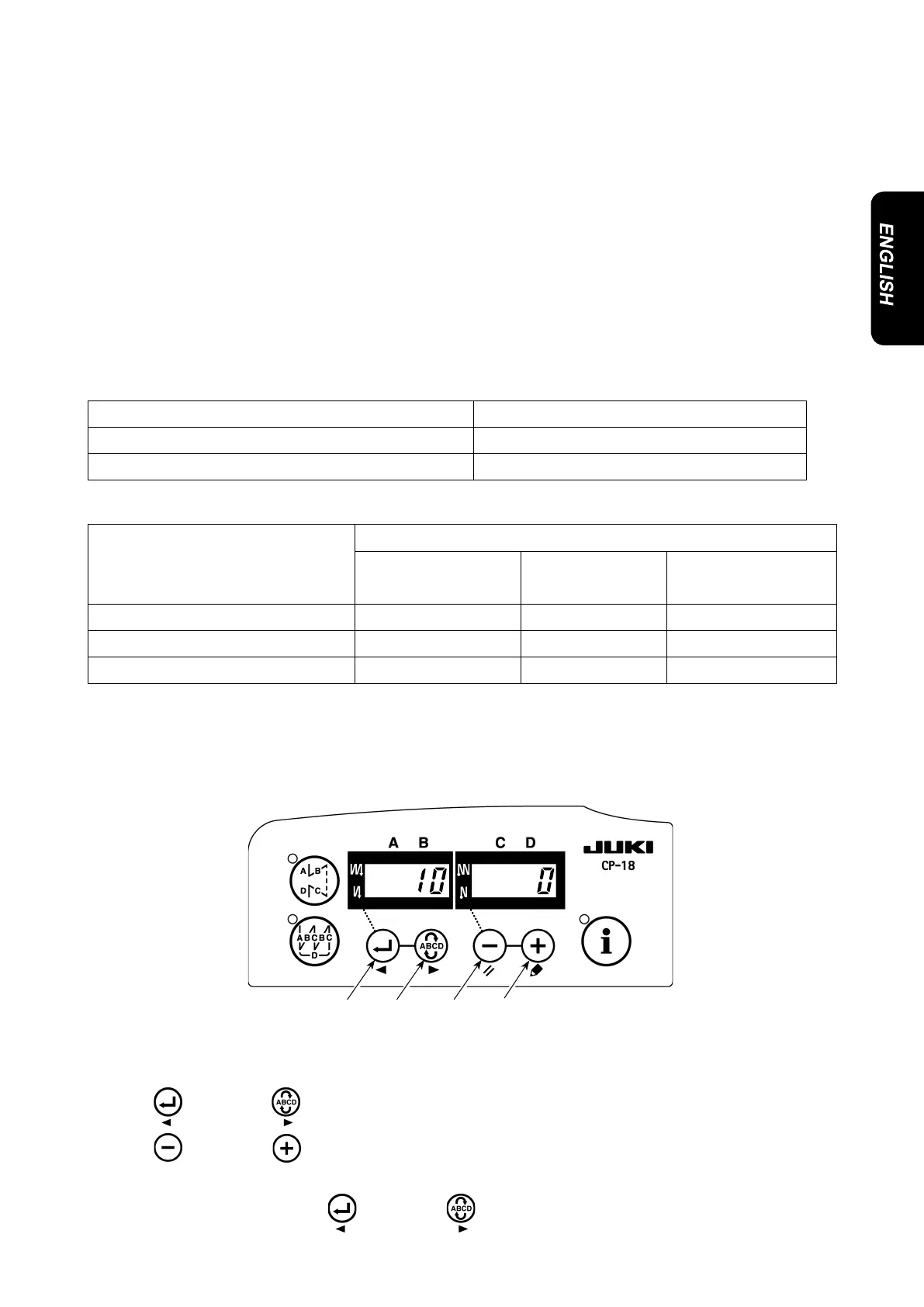

How to set the needle bar position when the machine is stopped

Make the setting by function No.10 (needle bar position setting when the machine is stopped).

1) Refer to "1. Setting of the mounted head, 1) How to enter into the function setting mode” and enter into

the function setting mode.

2) Press

switch

or switch

to call out function setting No.10.

3) Press

switch

or switch

and select "0” or "1”.

"0”….down position stop, "1”…..up position stop

4) After the setting is made, press

switch

or switch

, and turn the power OFF.

Loading...

Loading...